filmov

tv

How to Transition from Metal to PVC the RIGHT way

Показать описание

Chris shows you the proper way to transition from Metal to PVC connections.

We are a distributor of pumps, packaged pumping systems, on-site wastewater treatment equipment, on-site wastewater treatment systems, and custom electrical control panels for water and wastewater applications, water well supplies, drilling supplies, and water treatment equipment.

We are a distributor of pumps, packaged pumping systems, on-site wastewater treatment equipment, on-site wastewater treatment systems, and custom electrical control panels for water and wastewater applications, water well supplies, drilling supplies, and water treatment equipment.

Transition metals and their properties | Matter | Chemistry | FuseSchool

Transition Metals in Ionic Formulas

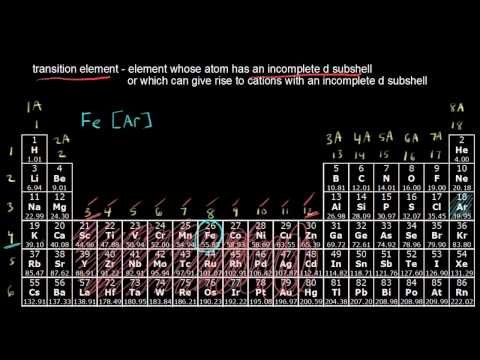

Transition Metals | Periodic table | Chemistry | Khan Academy

How to Transition from Metal to PVC the RIGHT way

How to install metal roof transition trim for Union's MasterRib panel.

27. Introduction to Transition Metals

Installing Transition Flashings on Metal Roofs

How to TRANSITION (PEX | COPPER | POLYB | CPVC | GALVANIZED) (COMPLETE GUIDE) | GOT2LEARN

The golden Tree #transition #shorts #youtubeshorts #ytshorts # #explore # #arabic #islamic

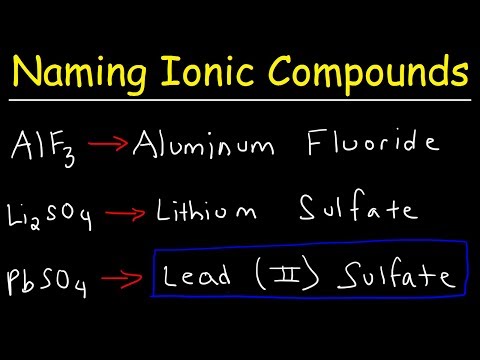

How To Name Ionic Compounds With Transition Metals

Introduction to Transition Metal Catalysis

Electronic Configuration - Transition Metals

Onsite metal fabrication - four-piece duct transition (Mechanical / sheet metal training #106)

How to Find the Number of Valence Electrons for Transition Metals

How to Find the Ionic Charge for Transition Metals

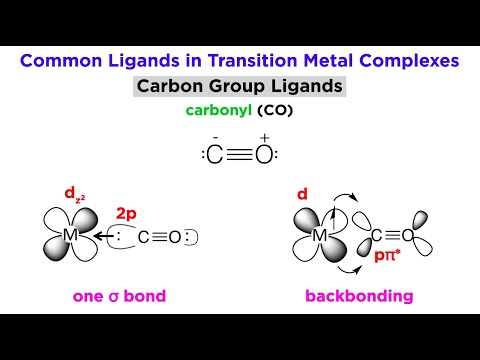

Types of Bonding in Transition Metal Systems and Simple Ligands

Installing a Heavy Duty PBR Metal Roof - Day 2: Transition

How To: Build Custom Sheetmetal Ductwork Transition | Step by Step Guide

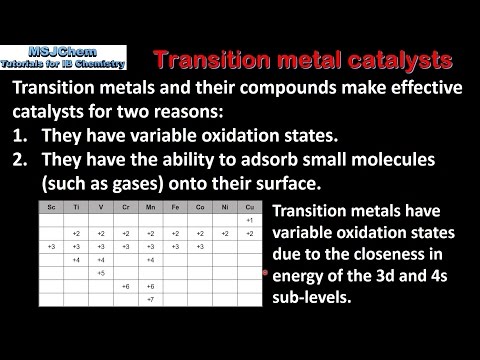

A.3 Transition metal catalysts (SL)

Writing Ionic Formulas with Transition Metals

Naming Ionic Compounds with Transition Metals Introduction

Metal transition

Why do Transition Metals Form Coloured Compounds?

Shingle to Metal Roof Transition - Istueta Roofing

Комментарии

0:03:21

0:03:21

0:08:12

0:08:12

0:05:34

0:05:34

0:07:15

0:07:15

0:01:47

0:01:47

0:43:31

0:43:31

0:05:18

0:05:18

0:08:15

0:08:15

0:00:09

0:00:09

0:13:33

0:13:33

0:09:38

0:09:38

0:04:14

0:04:14

0:34:38

0:34:38

0:05:29

0:05:29

0:05:18

0:05:18

0:11:54

0:11:54

0:20:09

0:20:09

0:25:16

0:25:16

0:01:49

0:01:49

0:07:21

0:07:21

0:10:10

0:10:10

0:06:39

0:06:39

0:12:15

0:12:15

0:04:56

0:04:56