filmov

tv

Before You Use Wago Wire Connectors

Показать описание

The details I have found out about them and why not to use them

Before You Use Wago Wire Connectors

Wago Connectors - EASY ways to connect 2 or more wires!

Which Splicing Device is Best? Push Ins Vs. Wago Vs. Wirenuts

How to use wago connector

Debunking the Pros: Can WAGO Lever Nuts Handle Heavy Electrical Loads?

THATS NOT HOW WAGO’S WORK!!!

New Wago Electric Connector is SHOCKING everyone - Inline 221 has arrived!

How do I use a Wago?

Is it necessary to use Wago connectors for all electrical wire connections? #electrican

How to use WAGO 221 Splicing Connectors

Use Wago Connectors instead of Wire Nuts

How to Use Wago Connectors - 221 Series Lever Nuts

Is it necessary to use Wago connectors for all electrical wire connections? #electrican

How does a WAGO connector work?

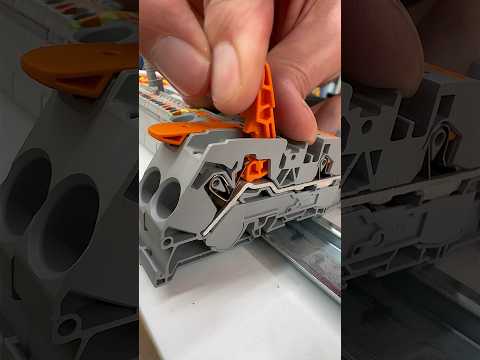

Uncovering the Hidden Test Points on Wago Connectors!

👷🏻♂️⚡️🔌💡 How to Use Wago Wire Connectors?👷🏻♂️⚡️🔌💡 Fast and Safe wire Connection...

The Secret To Removing Wires From a Wago 2773 Connector

Wago Connectors Compared | What Wire Connectors Are The Best?

What Wire Connector is the Best? Settling a Debate! Wire Nut VS Wago

What Wire Connector is the Best? Wire Nut VS Wago TESTED

How To Make The Perfect Connection With WAGO 221 Connectors

Massive WAGO 221 - For when you need More Power!

WAGO 221 Lever Nuts: Testing the Most Common Negative Feedback

WAGO 222 connectors review and demo. How to use with WAGOBOX Junction Box.

Комментарии

0:07:37

0:07:37

0:01:37

0:01:37

0:13:06

0:13:06

0:00:41

0:00:41

0:09:17

0:09:17

0:00:10

0:00:10

0:04:20

0:04:20

0:09:40

0:09:40

0:00:15

0:00:15

0:00:34

0:00:34

0:00:49

0:00:49

0:03:01

0:03:01

0:00:17

0:00:17

0:00:14

0:00:14

0:00:36

0:00:36

0:00:34

0:00:34

0:00:15

0:00:15

0:09:36

0:09:36

0:11:09

0:11:09

0:05:51

0:05:51

0:01:02

0:01:02

0:00:34

0:00:34

0:07:24

0:07:24

0:06:44

0:06:44