filmov

tv

Good or Garbage? Wire Splicing with Solder Sleeves.

Показать описание

It's not just any heat shrink tube - it's a genius invention with a solder ring inside. Simply slide the wires in, apply heat, and voila! Your work is complete.

Check out more heat shrink wizardry in our complete guide to Heat Shrink Tubing

#wires #soldering #heatshrink

Check out more heat shrink wizardry in our complete guide to Heat Shrink Tubing

#wires #soldering #heatshrink

Good or Garbage? Wire Splicing with Solder Sleeves.

Are Solder Seal Connectors BETTER than Butt Splices? (the truth)

Wago Connectors Compared | What Wire Connectors Are The Best?

Should We Use WAGOS or WIRENUTS?!?!

10 PROFESSIONAL solutions for Splice electrical Wires

How to Wire Up Ethernet Plugs the EASY WAY! (Cat5e / Cat6 RJ45 Pass Through Connectors)

How to use solder seal wire connectors?

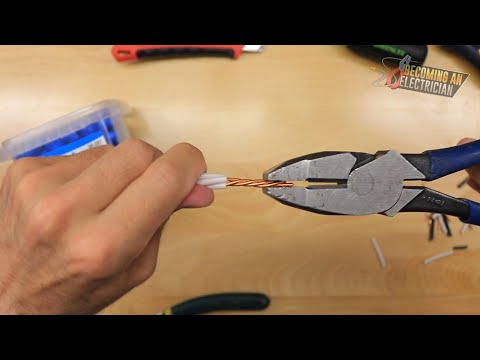

How to Splice Wires for Electricians

Low Heat Butt Connector Wire Splice Test

Wire Splicing easily connecting cables with a soldering iron - by VOGMAN

How to Splice Wires for the Very Best Connection

How to Terminate a Fiber Cable Using MetraAV's Termination Tools

10 Things You Didn't Know About Wire Connectors

In-Sure® Push-In Wire Connectors Instructional Video

Electronics Heat Shrink Self-Solder seal Butt Splice Connectors Waterproof connector?

Before You Use Wago Wire Connectors

Heat Shrinkable Wire Connectors

SOLDER & SEAL THE BEST WIRE CONNECTORS I HAVE FOUND

How To Use Solder Seal Wire Connectors

Self-soldering heat shrink connectors! Link in Description! #Wiring #solder #splice #HeatShrink

Electrical Wire Splicing Tips & Tricks #shorts #viral #electrical

Self Soldering Butt Splice Heat Shrink Connectors

DIY Hack, Heat Shrink Connectors - Where were you 20 years ago? #electrical #diy #handyman

Solder Seal Wire Connectors Heat Shrink Waterproof Electrical Wire Terminals Connectors Kit #shorts

Комментарии

0:00:22

0:00:22

0:13:02

0:13:02

0:09:36

0:09:36

0:13:50

0:13:50

0:10:52

0:10:52

0:06:17

0:06:17

0:00:39

0:00:39

0:16:36

0:16:36

0:09:47

0:09:47

0:13:06

0:13:06

0:15:39

0:15:39

0:13:45

0:13:45

0:11:12

0:11:12

0:01:56

0:01:56

0:00:29

0:00:29

0:07:37

0:07:37

0:00:38

0:00:38

0:05:51

0:05:51

0:03:38

0:03:38

0:01:00

0:01:00

0:00:13

0:00:13

0:02:12

0:02:12

0:00:25

0:00:25

0:00:29

0:00:29