filmov

tv

MIG Welding Travel Speed vs Stick Welding Travel speed

Показать описание

Subscribe to my channel for more weekly videos.

Wire fed welding processes like short circuit mig, spray mig, and dual shield flux core have very wide ranges of travel speeds.

Stick welding, while a very good welding process, has a much narrower range of travel speed.

Stick welding excels outdoors, for pipe welding, and one off welds or repairs.

But for production, wire fed processes can make you a lot more money.

Especially bare wire where this is no slag to chip and almost no cleanup.

Follow me on social media to see what I’m up to:

Join the discussion with thousands of welders at the Welding Tips & Tricks forum

Wire fed welding processes like short circuit mig, spray mig, and dual shield flux core have very wide ranges of travel speeds.

Stick welding, while a very good welding process, has a much narrower range of travel speed.

Stick welding excels outdoors, for pipe welding, and one off welds or repairs.

But for production, wire fed processes can make you a lot more money.

Especially bare wire where this is no slag to chip and almost no cleanup.

Follow me on social media to see what I’m up to:

Join the discussion with thousands of welders at the Welding Tips & Tricks forum

MIG Welding Travel Speed vs Stick Welding Travel speed

Travel Speed and Weld Profiles | MIG Monday

PrimeWeld MIG 180 Wire Speed Settings

Mig Welding Angles, Stickout and Travel Speed Explained

Setting Wire Speed On A Mig Welder To Match Voltage, Must See For Beginners Learning Welding

MIG Welding Wire Speed and Penetration

How NOT TO Weld: Most Common MIG Welding Mistakes

How does Wire Feed Speed Effect Your Weld? | MIG Monday

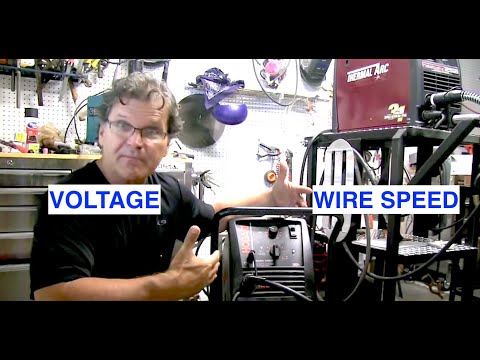

Mig Welding Basics part 3-Setting Voltage and Wire Speed

How To Calculate Inches Per Minute (ipm) For Travel Speed & Wire Speed

Basic mig welding technique for beginners

How to Make Consistent MIG Welds

Why ppl fail the mig Test #cwb #welding #migwelding #weldfail #studentwelder #weldingschool #welder

3F 2 Pass Vertical MIG Weld

Push vs. Pull Methods in MIG Welding

Guaranteed Better Mig Welds Or Your Money Back!

MIG Welder Settings: MIG Welding Basics for Beginners

3 MIG Welding Tips From A Welding Instructor

Simple technique welding Mig-Mag #welding #sorts

Finding the right travel speed stick welding #welding

GMAW Welding Process Variables- Travel Speed &Travel Angle

Controlling Your Bead With Travel Speed

beginner welding mig # #migwelding #sorts

115 Volt MIG Welding Techniques & Settings

Комментарии

0:04:40

0:04:40

0:04:23

0:04:23

0:06:54

0:06:54

0:04:12

0:04:12

0:06:40

0:06:40

0:07:37

0:07:37

0:16:44

0:16:44

0:07:03

0:07:03

0:12:31

0:12:31

0:04:05

0:04:05

0:00:16

0:00:16

0:04:53

0:04:53

0:01:01

0:01:01

0:03:16

0:03:16

0:01:17

0:01:17

0:59:18

0:59:18

0:07:44

0:07:44

0:00:49

0:00:49

0:00:22

0:00:22

0:00:42

0:00:42

0:07:14

0:07:14

0:00:54

0:00:54

0:00:32

0:00:32

0:05:55

0:05:55