filmov

tv

3 MIG Welding Tips From A Welding Instructor

Показать описание

Our Fab School instructor Miguel shares 3 MIG welding tips for beginners.

3 MIG Welding Tips From A Welding Instructor

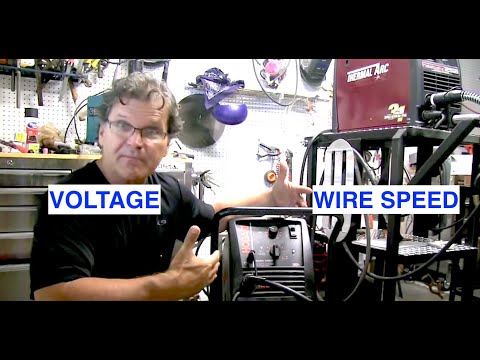

Mig Welding Basics part 3-Setting Voltage and Wire Speed

Simple MIG Welding Technique - Flat, Horizontal, Vertical & Overhead | Welding Tips & Tricks...

Perfect Mig Welder Settings in 3 Easy Steps

3F 2 Pass Vertical MIG Weld

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

GMAW-S 3G Test Plate

HOW TO MIG LIKE TIG WELD (Stacking Dimes) W/ OVERKILLRACINGANDCHASSIS w/ *Tips and Techniques*

3 Tips for MIG Welding in Windy Weather

How NOT TO Weld: Most Common MIG Welding Mistakes

How to Make Consistent MIG Welds

MIG Welding Basics For Beginners

Simple technique welding Mig-Mag #welding #sorts

MIG Welding 3g Vertical Open Root Plate Test

MIG Welder Settings: MIG Welding Basics for Beginners

MIG Welding Techniques - 3G Position Open Root +Hot Pass Walking - Technika Spawania MIG-MAG

HOW TO GET NEAT MIG WELDS IN 3 STEPS

Short Circuit Mig Fillet Welds and more...

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

not everyone know about this SIMPLE Mig Mag welding technique

MIG Settings for any Thickness

3G MIG Uphill Pulse Spray vs Short Circuit

MIG Welding 3g Plate Uphill Root vs Downhill

MIG Welding Aluminum with a Spool Gun

Комментарии

0:12:31

0:12:31

0:07:18

0:07:18

0:09:46

0:09:46

0:03:16

0:03:16

0:22:14

0:22:14

0:07:45

0:07:45

0:06:20

0:06:20

0:03:23

0:03:23

0:16:44

0:16:44

0:04:53

0:04:53

0:14:40

0:14:40

0:00:22

0:00:22

0:06:05

0:06:05

0:07:44

0:07:44

0:09:09

0:09:09

0:11:08

0:11:08

0:10:21

0:10:21

1:15:34

1:15:34

0:03:03

0:03:03

0:09:32

0:09:32

0:06:29

0:06:29

0:06:29

0:06:29

0:01:00

0:01:00