filmov

tv

PrimeWeld MIG 180 Wire Speed Settings

Показать описание

Another Mig Welding video using 115 volt on a 20 amp circuit.

The primeweld mig180 has a good settings chart inside the wire feeder door.

Settings for 1/8" thick steel were listed at 18 volts and 236 inches per minute with .035" er70s6 wire and C25 gas (75 argon 25 co2).

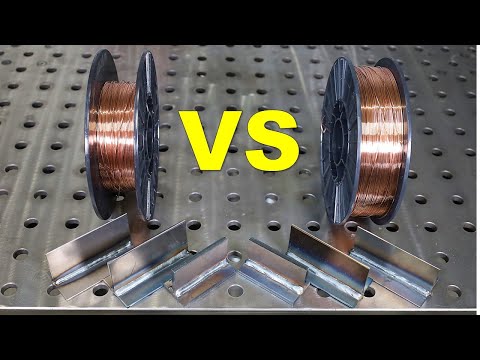

What happens when you lower wire speed too much?

and what happens when your wire speed is too high for a given voltage?

WIre speed controls amperage but you also need adequate voltage in order to have an efficient arc.

Join the discussion with thousands of welders at the Welding Tips & Tricks forum

The primeweld mig180 has a good settings chart inside the wire feeder door.

Settings for 1/8" thick steel were listed at 18 volts and 236 inches per minute with .035" er70s6 wire and C25 gas (75 argon 25 co2).

What happens when you lower wire speed too much?

and what happens when your wire speed is too high for a given voltage?

WIre speed controls amperage but you also need adequate voltage in order to have an efficient arc.

Join the discussion with thousands of welders at the Welding Tips & Tricks forum

PrimeWeld MIG 180 Wire Speed Settings

MIG Welding Settings and Techniques Tested - PrimeWeld MIG180

Setup and testing of my new Primeweld Mig 180

Bought #PRIMEWELD MiG 180 end of Oct 2023 hard to set wire speed and won’t weld right no solution…...

PRIMEWELD Mig 180 One Year Review NOT SPONSERD ( 2022 )

Prime Weld MiG 180 unboxing and testing

Setting Wire Speed On A Mig Welder To Match Voltage, Must See For Beginners Learning Welding

Prime Weld Mig 180 First looks!!

115 Volt MIG Welding Techniques & Settings

Primeweld MIG 180 Welder| Welding machines

PrimeWeld Mig180 Update

PRIMEWELD MIG 180 REVIEW AND THE CT520DP

Prime Weld Mig 180 Review (Under $600 !!!!)

Prime weld Mig 180 settings and techniques

SALDATRICE PRIMEWELD MIG 180 + SPOOLGUN (ALLUMINIO) | MMA/MIG MAG/FLUX CORE/ALLUMINIUM | FROM USA

MIG Welding Overhead PrimeWeld MIG180 on 115volt

PrimeWeld MIG180 SPOOL GUN Aluminum

Are Expensive MIG Welders a Ripoff? Let’s Settle This!

New #primeweld mig 180 wire setting problem only adjusts by 4 while trying to set wire speed?

PrimeWeld Mig180 Mig Welder And Stick Welder

MIG Welding Settings and Techniques Tested - PrimeWeld MIG180

Perfect Mig Welder Settings in 3 Easy Steps

#1 Tip and Trick to Improve Flux Core Welding

MIG Welding: What Size Wire Should I Use?

Комментарии

0:06:54

0:06:54

0:05:26

0:05:26

0:14:09

0:14:09

0:00:53

0:00:53

0:07:52

0:07:52

0:32:23

0:32:23

0:06:40

0:06:40

0:12:02

0:12:02

0:05:55

0:05:55

0:15:57

0:15:57

0:09:29

0:09:29

0:01:38

0:01:38

0:19:52

0:19:52

0:23:46

0:23:46

0:28:26

0:28:26

0:04:12

0:04:12

0:02:23

0:02:23

0:15:46

0:15:46

0:00:47

0:00:47

0:14:07

0:14:07

0:00:34

0:00:34

0:09:46

0:09:46

0:04:16

0:04:16

0:05:50

0:05:50