filmov

tv

Cycloidal Drives Made Easy: Design, Build, and Test with Fusion 360

Показать описание

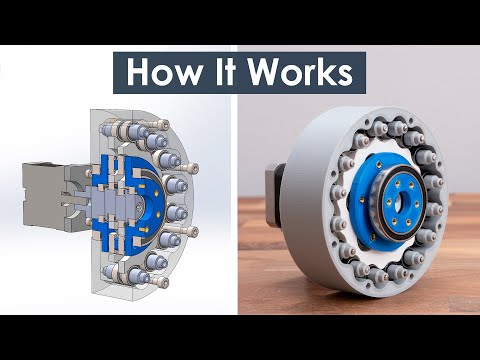

This video covers the concept, design, and build of 3D printed cycloidal drives, and why they're the best gearbox actuator.

If you have any questions feel free to ask in the comments.

Animations were used that are owned by - @HowToMechatronics - I do not own the rights to these animations.

Cycloidal Drive API:

SolidWorks Cycloidal Drive (Omar Younis):

My GitHub:

Parts List:

- NEMA23 Stepper Motor

- TB6600 Driver

- PLA+ Filament

- Nylon Spacers

- Ball Bearings

- M3 Screws

00:00 - Intro to Cycloidal Drives

00:38 - Understanding Cycloidal Drives

01:45 - Inside a Cycloidal Drive

03:00 - idk

03:59 - Understanding Eccentricity

05:08 - Designing Cycloidal Drives

06:36 - Designing in Fusion360

07:41 - Implementation of Bearings (Budget)

08:51 - Building my Cycloidal Gearbox

10:37 - Testing my Cycloidal Gearbox

Music:

New Life - Noire

If you have any questions feel free to ask in the comments.

Animations were used that are owned by - @HowToMechatronics - I do not own the rights to these animations.

Cycloidal Drive API:

SolidWorks Cycloidal Drive (Omar Younis):

My GitHub:

Parts List:

- NEMA23 Stepper Motor

- TB6600 Driver

- PLA+ Filament

- Nylon Spacers

- Ball Bearings

- M3 Screws

00:00 - Intro to Cycloidal Drives

00:38 - Understanding Cycloidal Drives

01:45 - Inside a Cycloidal Drive

03:00 - idk

03:59 - Understanding Eccentricity

05:08 - Designing Cycloidal Drives

06:36 - Designing in Fusion360

07:41 - Implementation of Bearings (Budget)

08:51 - Building my Cycloidal Gearbox

10:37 - Testing my Cycloidal Gearbox

Music:

New Life - Noire

Cycloidal Drives Made Easy: Design, Build, and Test with Fusion 360

Wow I Didn't Know it's so EASY to Design Cycloidal Drives

What makes cycloidal gearboxes so amazing?

design a cycloidal gear step by step

Cycloidal Gearbox Explained - How does it work?

What is Cycloidal Drive? Designing, 3D Printing and Testing

Harmonic vs Cycloidal Drive - Torque, Backlash and Wear Test

Designing a cycloidal drive in Python and Fusion 360

Experiments with Cycloidal Drives

How to Design a Cycloidal Disk in Fusion 360

Of Cycloid reducer

Building an Internal Cycloidal Robotic Actuator

How to Design a Cycloidal Drive for Robot Actuator Module!

Super satisfying cycloidal drive build 👀⚙️| #3dprinting #robotics #arduino #mechanical #engineering...

Let’s build a cycloid drive! (Full project video coming soon!) #3dprinting #robotics #engineering

3d Printed Cycloidal Drive for Robot Arms

Animation Wankel/cycloidal gearbox design for High RPM's motor in OpenSCAD. Easily 3D printable...

Cycloidal Drive 📌, Cycloidal Speed Reducer #mechanical #engineering #solidworks #cad #shorts #short...

Design cycloidal gearbox 3:1 ratio with pinion multiplier. Animation with OpenSCAD.

DIY Cycloidal Laser-Cut All-Metal Robotic Actuator: Durable!

What makes planetary gearboxes so amazing?

Manufacturing of a Cycloidal Reducer for a Robot Arm joint

A New Take On The Cycloidal Drive (Extremely Compact)

Cycloidal Actuator V2 - free to download in video description #3dprinting #robotics

Комментарии

0:12:33

0:12:33

0:04:40

0:04:40

0:04:33

0:04:33

0:04:02

0:04:02

0:00:59

0:00:59

0:16:36

0:16:36

0:21:23

0:21:23

0:07:59

0:07:59

0:15:05

0:15:05

0:16:32

0:16:32

0:00:08

0:00:08

0:19:01

0:19:01

0:17:41

0:17:41

0:00:31

0:00:31

0:00:31

0:00:31

0:05:00

0:05:00

0:00:17

0:00:17

0:00:16

0:00:16

0:00:17

0:00:17

0:10:02

0:10:02

0:09:59

0:09:59

0:04:06

0:04:06

0:08:19

0:08:19

0:00:14

0:00:14