filmov

tv

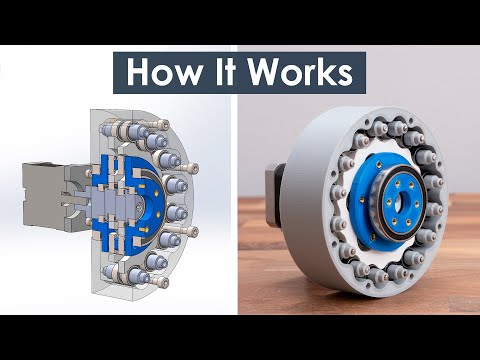

How to Design a Cycloidal Drive for Robot Actuator Module!

Показать описание

This video is a guideline of how to design a cycloidal disc for a cycloidal drive gear. On this tutorial, I am using Solidworks and a python script to generate a parametic equation for a cycloidal disc.

If you have a good plan of a hardware such as bearing size, pin, and standard parts you want to use, you should use that as a constrain and adjust the design parameters on sketch diagram to make sure that your cycloidal disc will fit perfectly.

For more detail about research papers.

- Build A Cycloidal Drive with Solidworks by Omar Younis

- Cycloid vs. Harmonic Drives for use in High Ratio, Single Stage Robotic Transmissions by Jonathon W. Sensinger

- Design And Application Guidelines For Cycloid Drives With Machining Tolerances by D. C. H. YANG

- Efficiency of High-Sensitivity Gear Trains, Such as

Cycloid Drives by Jonathon W. Sensinger

- On the lobe profile design in a cycloid reducer using instant velocity center by Joong-Ho Shin, Soon-Man Kwon

- Unified Approach to Cycloid Drive Profile, Stress, and Efficiency Optimization by Jonathon W. Sensinger

More Robot Projects:

BG Music credit:

If you have a good plan of a hardware such as bearing size, pin, and standard parts you want to use, you should use that as a constrain and adjust the design parameters on sketch diagram to make sure that your cycloidal disc will fit perfectly.

For more detail about research papers.

- Build A Cycloidal Drive with Solidworks by Omar Younis

- Cycloid vs. Harmonic Drives for use in High Ratio, Single Stage Robotic Transmissions by Jonathon W. Sensinger

- Design And Application Guidelines For Cycloid Drives With Machining Tolerances by D. C. H. YANG

- Efficiency of High-Sensitivity Gear Trains, Such as

Cycloid Drives by Jonathon W. Sensinger

- On the lobe profile design in a cycloid reducer using instant velocity center by Joong-Ho Shin, Soon-Man Kwon

- Unified Approach to Cycloid Drive Profile, Stress, and Efficiency Optimization by Jonathon W. Sensinger

More Robot Projects:

BG Music credit:

Комментарии

0:05:36

0:05:36

0:04:02

0:04:02

0:07:59

0:07:59

0:16:32

0:16:32

0:04:33

0:04:33

0:17:41

0:17:41

0:16:35

0:16:35

0:00:06

0:00:06

0:18:36

0:18:36

0:05:00

0:05:00

0:01:03

0:01:03

0:00:15

0:00:15

0:04:40

0:04:40

0:00:47

0:00:47

0:00:41

0:00:41

0:12:33

0:12:33

0:34:30

0:34:30

0:21:23

0:21:23

0:05:20

0:05:20

0:19:01

0:19:01

0:12:14

0:12:14

0:00:59

0:00:59

0:05:04

0:05:04

0:00:13

0:00:13