filmov

tv

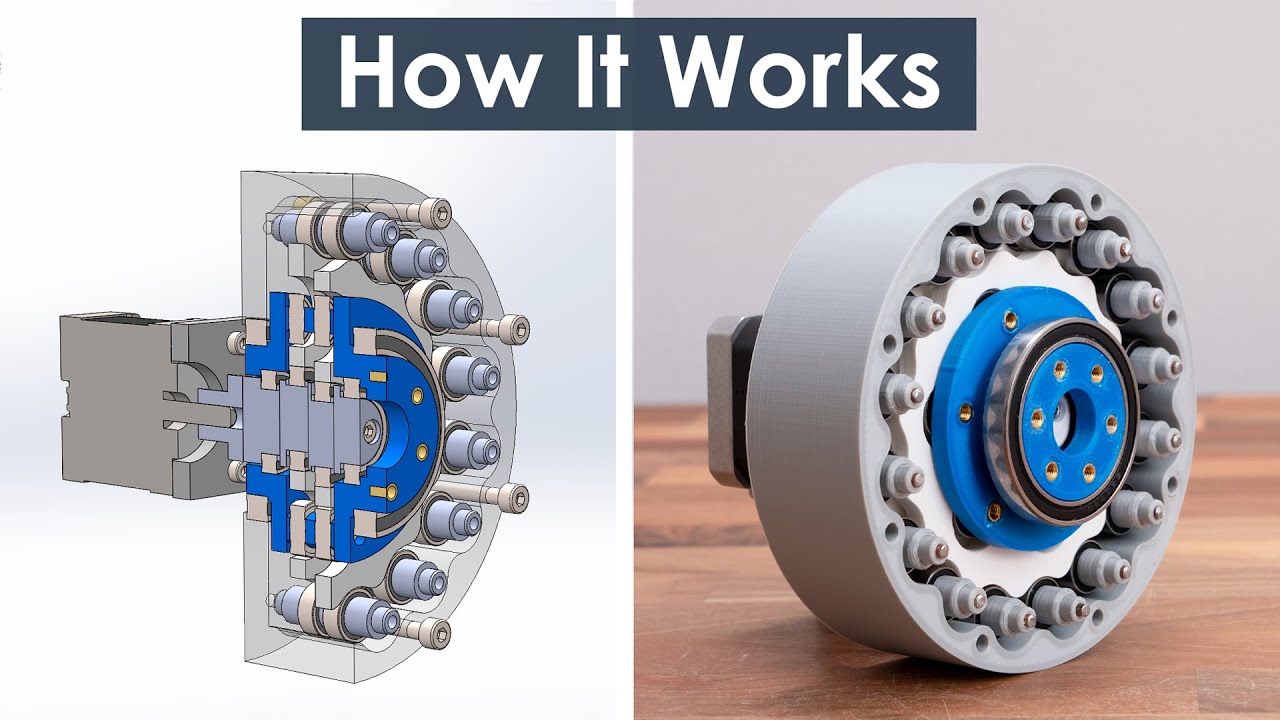

What is Cycloidal Drive? Designing, 3D Printing and Testing

Показать описание

Parts list (check website article for full list, affiliate links):

AliExpress:

Like my page on Facebook:

What is Cycloidal Drive? Designing, 3D Printing and Testing

What makes cycloidal gearboxes so amazing?

design a cycloidal gear step by step

Wow I Didn't Know it's so EASY to Design Cycloidal Drives

Cycloidal Gearbox Explained - How does it work?

Designing a cycloidal drive in Python and Fusion 360

Harmonic vs Cycloidal Drive - Torque, Backlash and Wear Test

How to Design a Cycloidal Disk in Fusion 360

How to Design a Cycloidal Drive for Robot Actuator Module!

Cycloids

Cycloidal Drives Made Easy: Design, Build, and Test with Fusion 360

CNC Machined vs 3D Printed Cycloidal Drive

SolidWorks Tutorial #305 : Cycloidal drive

What is a Cycloidal Gear-- A GalcoTV Tech Tip | Galco

Cycloid drive (RV reducer) working principle

What Is a Cycloidal Drive

Experiments with Cycloidal Drives

Building an Internal Cycloidal Robotic Actuator

I designed and built a 3D printed Cycloidal Gearbox

120Nm 3D Printed Cycloidal Drive

Cycloidal Drive #1 - 3D Printed Gearbox 40:1

3D Printed Cycloidal Drive | What They Are, How They Work, and Testing

Cycloidal Drive 🙌 #new #mechanism #cad #3danimation #mechanical #engineers #designproject #3dvisual...

Manufacturing a Cycloidal Drive with a Shapeoko Pro CNC Machine

Комментарии

0:16:36

0:16:36

0:04:33

0:04:33

0:04:02

0:04:02

0:04:40

0:04:40

0:00:59

0:00:59

0:07:59

0:07:59

0:21:23

0:21:23

0:16:32

0:16:32

0:17:41

0:17:41

0:00:41

0:00:41

0:12:33

0:12:33

0:19:58

0:19:58

0:30:16

0:30:16

0:01:53

0:01:53

0:00:23

0:00:23

0:02:50

0:02:50

0:15:05

0:15:05

0:19:01

0:19:01

0:00:15

0:00:15

0:19:44

0:19:44

0:00:31

0:00:31

0:13:00

0:13:00

0:00:06

0:00:06

0:17:42

0:17:42