filmov

tv

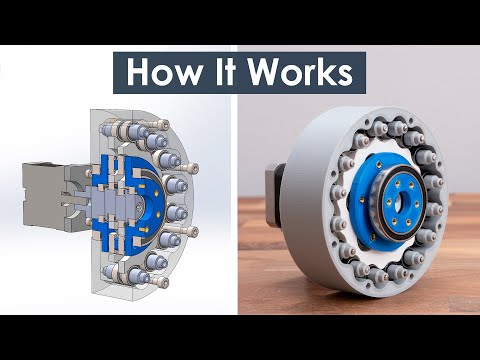

3d Printed Cycloidal Drive for Robot Arms

Показать описание

Designing and building a 3d Printed 20:1 cycloidal reducer / actuator to increase the torque from a stepper motor.

These are the supplies i used:

These are the supplies i used:

Cycloidal vs Belt vs Planetary - The Best 3D Printed Drive for Your Next Robotic Project?

A 3D printed Cycloid Gearbox with two rotors (and suggested improvements)

What makes cycloidal gearboxes so amazing?

3d Printed Cycloidal Drive for Robot Arms

120Nm 3D Printed Cycloidal Drive

3D Printed Cycloidal Drive V2 - Much Better!

3D Printed 20:1 Cycloidal Drive #cycloidaldrive #electricmotors #3dprinting

3D printed Cycloidal Drive BLDC servo V2

26:1 Cycloidal Drive vs 20:1 Micro-Drive #3dprinting #diyrobot #roboticarm #cycloidaldrive #robotic

Harmonic vs Cycloidal Drive - Torque, Backlash and Wear Test

3D printed cycloidal gear drive 36:1

What is Cycloidal Drive? Designing, 3D Printing and Testing

I designed and built a 3D printed Cycloidal Gearbox

CNC Machined vs 3D Printed Cycloidal Drive

3D Printed Planetary Cycloidal Hub Gearbox. How far can it drive?

3D Printed Cycloidal Gearbox!

Mini Cycloidal Drive 1-11 - no backlash

3D printed cycloidal gearbox build and tolerance

3D printed Cycloidal Drive with 31:1 backdrivable

3D Printed Cycloidal Gear Drive

Cycloidal drive - nema17 3d printed

3d printed cycloidal drive!! #3dprinting

Cycloidal Drives Made Easy: Design, Build, and Test with Fusion 360

Internal Motor Cycloidal Gear - 3D printed - Amazing 47:1 Reduction! #3dprinting #technology

Комментарии

0:29:16

0:29:16

0:10:21

0:10:21

0:04:33

0:04:33

0:05:00

0:05:00

0:19:44

0:19:44

0:17:14

0:17:14

0:00:23

0:00:23

0:02:18

0:02:18

0:00:18

0:00:18

0:21:23

0:21:23

0:00:25

0:00:25

0:16:35

0:16:35

0:00:15

0:00:15

0:19:58

0:19:58

0:08:56

0:08:56

0:00:14

0:00:14

0:00:46

0:00:46

0:02:13

0:02:13

0:00:17

0:00:17

0:00:15

0:00:15

0:00:15

0:00:15

0:00:20

0:00:20

0:12:33

0:12:33

0:00:15

0:00:15