filmov

tv

How to solder properly, even with poor tools #soldering #electronics #microscope #arduino

Показать описание

In this video, I show you how to achieve good solder joints.

I intentionally used my old and subpar soldering iron to show that good solder joints are achievable with even this equipment.

I intentionally used my old and subpar soldering iron to show that good solder joints are achievable with even this equipment.

How to solder properly, even with poor tools #soldering #electronics #microscope #arduino

Using Flux | Soldering Basics | Soldering for Beginners

Soldering tips and tricks - Tip 11 Use the right quantity of solder and temperature when soldering!

Don't solder When Flux Evaporates! Here's Why...

How To Use Solder Paste | Short Video #soldering #shorts

How to Tin a Soldering Iron Tip

Leaded vs. Lead-Free Solder Wire: How Tin Content Impacts Your Soldering Results!

5 SECRETS TO PERFECT SILVER SOLDERING!

solder not sticking to tip #shorts #hack

Hands-free solder feed. No tools required other than a normal soldering iron.

Soldering iron Cleaning || iron bit cleaner || Tip Cleaner #soldering_iron #solderingtips #soldering

PJLSW - 858D Hot Air Rework Station first time use

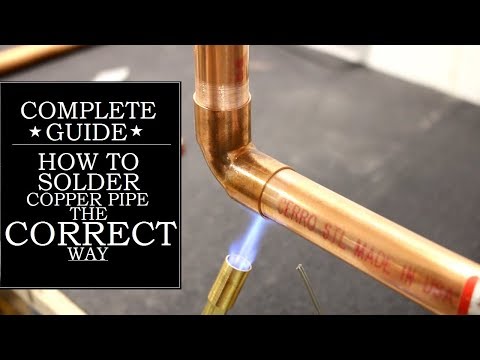

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

SOLDERING MISTAKE #2 (heat quantity)

secret trick stick welding , why no welders talk about this

How to solder properly-Part 1 | THT

How To solder small Components on DIY PCB

Top 4 Soldering MISTAKES That RUIN Your Projects #SHORTS

BGA Soldering by hand with no template #electronicsrepair #ecurepair #soldering #rework #shorts

How to quickly clean a soldering iron tip #lifehack #soldering #mixerdiy #idea

3 Common Soldering Mistakes (part 1) FLUX #shorts #plumbing #plumber #soldering #fluxo

Soldering Wires to Components the RIGHT WAY #SHORTS

Required Tools and Supplies For Basic Soldering | Soldering Basics | Soldering for Beginners

How i desolder and solder the part of Joystick from PS4 and PS5 Dual Sense controller

Комментарии

0:01:00

0:01:00

0:03:25

0:03:25

0:00:40

0:00:40

0:00:44

0:00:44

0:00:14

0:00:14

0:03:32

0:03:32

0:00:18

0:00:18

0:13:47

0:13:47

0:00:44

0:00:44

0:02:38

0:02:38

0:00:21

0:00:21

0:00:47

0:00:47

0:05:05

0:05:05

0:01:00

0:01:00

0:00:31

0:00:31

0:03:32

0:03:32

0:09:16

0:09:16

0:00:25

0:00:25

0:00:58

0:00:58

0:00:16

0:00:16

0:00:42

0:00:42

0:00:37

0:00:37

0:03:13

0:03:13

0:03:27

0:03:27