filmov

tv

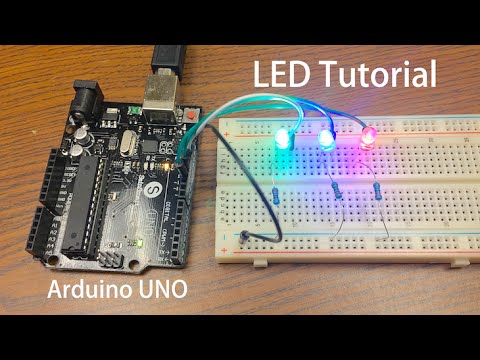

How to Turn an LED On

Показать описание

Below are my Super Patrons with support to the extreme!

Sam Lutfi

J4yC33

By: Mehdi Sadaghdar

How to Turn an LED On

Arduino Blinking LED Tutorial

Bending LED Flexible Strips | Inspired LED

How To Convert T8 Fluorescent Lights to LED ● Explained in Simple Terms

Building DIY LED lights

How to connect LED light with switch using battery

How to fix led strip light remote (very simple)

LED Light Remote Explained

LED Turn Signal Light Conversion

proper way to wire led lights

Arduino Tutorial: LED Sequential Control- Beginner Project

How to Turn on 2 LED lights with Arduino and Breadboard

Fluorescent to LED Conversion

How to test LEDs using a cheap digital multimeter (Cylindrical, SMD LED)

How to Connect Multiple LED's with 9V Battery, Switch in Series Connection | Simple Electric Ci...

How To Make An LED Circuit Using Breadboard At Home | Easy DIY

How to Install a Magnetic Switch for LED Lighting in Cabinets and Drawers | Inspired LED

How to Bend LED Strips Around Corners

How to Fix Your LED Turn Signal Bulbs that Don't Flash. Make Them Blink! | @WiringRescue

Battery Replacement For RGB Led Remote | RGB remote Cap Open | Led Strip Lights

How to Connect Single LED to 9V Battery with Resistor & ON/OFF Switch | Connection Tutorials

How to Wire an LED Strip to a Switch

LED Strip Light RGB Controller Installation Guide step by step, led strip lights amazon, led strip

Watch this before buying LEDs

Комментарии

0:17:00

0:17:00

0:02:50

0:02:50

0:00:52

0:00:52

0:05:19

0:05:19

0:14:12

0:14:12

0:01:39

0:01:39

0:02:05

0:02:05

0:05:54

0:05:54

0:00:28

0:00:28

0:02:28

0:02:28

0:03:53

0:03:53

0:05:06

0:05:06

0:05:21

0:05:21

0:05:54

0:05:54

0:03:13

0:03:13

0:04:32

0:04:32

0:01:02

0:01:02

0:01:57

0:01:57

0:05:10

0:05:10

0:01:35

0:01:35

0:02:17

0:02:17

0:02:53

0:02:53

0:05:38

0:05:38

0:19:47

0:19:47