filmov

tv

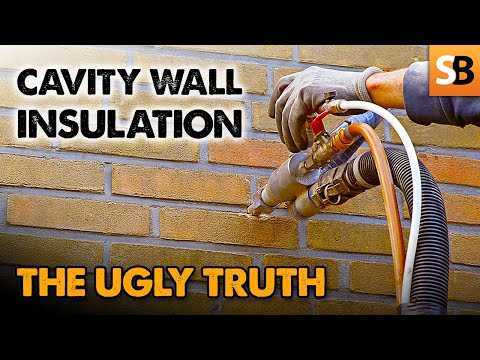

Brickwork & Insulation | Building an Extension #4

Показать описание

In Part 4 of our series following the building of an extension we cover the brickwork and insulation stage and some points to consider when insulating your home.

In this episode Roger Bisby explains the benefits of using Rigid thermal PIR insulation, an alternative to mineral wool fibre insulation. Installing insulation such as PIR board insulation can help make a home warmer and reduce energy costs.

Thanks to its high rate of return per square metre Rigid thermal PIR home insulation can help increase energy efficiency and achieve part-L compliance.

EcoTherm insulation has a lambda value of just 0.021 – 0.027 W/mk. For example: By using a 100 mm thick Eco-Versal board you can achieve a thermal resistance (R value) of 4.55m2K/W . To achieve the same value with traditional insulation you may require up to 200mm thickness of insulation.

In the case of this project using Ecotherm Insulation Boards has helped the homeowner to significantly exceed the insulation requirements which means they can increase the extensions's glazed area with the addition of large windows and bi-fold doors. This made this sustainable insulation material the best insulation for their requirements.

As ever this episode of the extension series covers technology, tips and techniques designed to help anyone undertaking building work.

Episode 4 features:

Building a brick pier to support the steel beams

Putting in wall ties

Cutting a thermalite block with an Irwin block saw

How to cut a block with a hammer and bolster

Damp proof course going in on the outer skin

When and why you need an expansion joint in your brickwork to prevent cracking

The insulation installation

Don't forget to subscribe to our channel to keep up to date with all of the latest episodes.

===================================================

Don't forget to stay up to date with Skill Builder!

In this episode Roger Bisby explains the benefits of using Rigid thermal PIR insulation, an alternative to mineral wool fibre insulation. Installing insulation such as PIR board insulation can help make a home warmer and reduce energy costs.

Thanks to its high rate of return per square metre Rigid thermal PIR home insulation can help increase energy efficiency and achieve part-L compliance.

EcoTherm insulation has a lambda value of just 0.021 – 0.027 W/mk. For example: By using a 100 mm thick Eco-Versal board you can achieve a thermal resistance (R value) of 4.55m2K/W . To achieve the same value with traditional insulation you may require up to 200mm thickness of insulation.

In the case of this project using Ecotherm Insulation Boards has helped the homeowner to significantly exceed the insulation requirements which means they can increase the extensions's glazed area with the addition of large windows and bi-fold doors. This made this sustainable insulation material the best insulation for their requirements.

As ever this episode of the extension series covers technology, tips and techniques designed to help anyone undertaking building work.

Episode 4 features:

Building a brick pier to support the steel beams

Putting in wall ties

Cutting a thermalite block with an Irwin block saw

How to cut a block with a hammer and bolster

Damp proof course going in on the outer skin

When and why you need an expansion joint in your brickwork to prevent cracking

The insulation installation

Don't forget to subscribe to our channel to keep up to date with all of the latest episodes.

===================================================

Don't forget to stay up to date with Skill Builder!

Комментарии

0:20:14

0:20:14

0:00:27

0:00:27

0:00:23

0:00:23

0:00:15

0:00:15

0:01:30

0:01:30

0:00:12

0:00:12

0:00:16

0:00:16

0:00:17

0:00:17

0:09:38

0:09:38

0:00:17

0:00:17

0:00:39

0:00:39

0:03:01

0:03:01

0:00:36

0:00:36

0:10:59

0:10:59

0:00:11

0:00:11

0:00:20

0:00:20

0:02:34

0:02:34

0:13:29

0:13:29

0:02:09

0:02:09

0:01:37

0:01:37

0:04:29

0:04:29

0:02:24

0:02:24

0:14:00

0:14:00

0:10:02

0:10:02