filmov

tv

Introduction to Proportional Integral (PI) Control

Показать описание

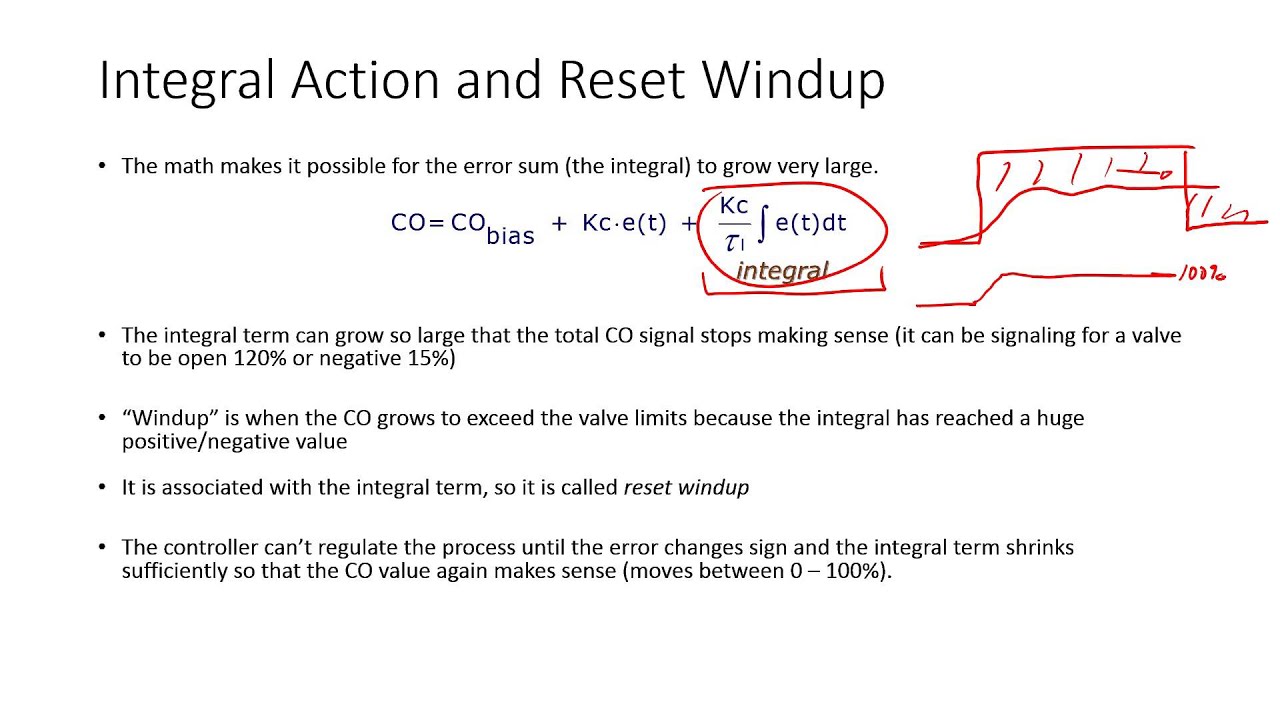

Proportional Integral (PI) controllers are the most popular industrial applications of PID controllers. These controllers have no derivative component and typically have only 2 tuning parameters. Those tuning parameters are terms that enhance either the term that is proportional to the controller error or else the term that is proportional to the integral of the error.

Introduction to Proportional Integral (PI) Control

PID Controller Explained

PID Control - A brief introduction

Proportional Integral PI Controller

#182 P, PI, PD, PID controllers || EC Academy

What is a PID Controller?

Introduction to PID Control

PID Control: The Basics #shorts #thecircuithelper

VLSI INTRODUCTION CLASS

PIDs Simplified

What is a PID Controller? | DigiKey

What Is PID Control? | Understanding PID Control, Part 1

Proportional Integral (PI) controller and its limitations

How to Tune a PID Controller

Control Bootcamp: Cruise Control Example with Proportional-Integral (PI) control

Design of Proportional Integral ( PI ) Controller | Simplified Control Systems EC 409 KTU S7

P, PI, and PD variants of PID control (Kevin Lynch)

P, PI, PD, and PID Controllers: A Comparative Analysis in Control System Engineering

How a PI Controller works inside a VFD Speed Control system

pi pd pid controllers

Intro To Proportional Control

pid controller | instrumentation | proportional integral derivative controller

Effect Proportional Integral PI Controller

PID Control (Proportional -- Integral -- Derivative) A brief introduction

Комментарии

0:14:48

0:14:48

0:09:25

0:09:25

0:07:44

0:07:44

0:10:53

0:10:53

0:04:51

0:04:51

0:05:39

0:05:39

0:49:18

0:49:18

0:00:46

0:00:46

0:53:44

0:53:44

0:13:07

0:13:07

0:22:19

0:22:19

0:11:42

0:11:42

0:13:52

0:13:52

0:08:43

0:08:43

0:23:17

0:23:17

0:06:22

0:06:22

0:02:42

0:02:42

0:11:36

0:11:36

0:05:35

0:05:35

0:11:28

0:11:28

0:07:25

0:07:25

0:05:53

0:05:53

0:15:42

0:15:42

0:07:44

0:07:44