filmov

tv

Metal Lathe Basics

Показать описание

SUPPORT MY CHANNEL: Channel Sticker are NOW available here for a small donation.

(Please donate at least $3.00 to cover printing and postage)

THANK YOU FOR YOUR SUPPORT!

(Please donate at least $3.00 to cover printing and postage)

THANK YOU FOR YOUR SUPPORT!

Metal Lathe Tutorial 1 : Theory

Metal Lathe Basics Tutorial | How To Use A Metal Lathe

How to Use a Metal Lathe - Kevin Caron

Learning to Use a Lathe, Part 1: Basic operation and facing cut

Metal Lathe Work Holding Tips: Beginner lathe techniques

Metal Lathe Basics

Every shop needs a metal lathe.

Tormach's Beginner Guide to Lathe Tooling

A wonderful technique that every machinist should know .

Mini Lathe Basic Setup and Operation - Start Machining in YOUR Home Shop! Eastwood

Metal Lathe Tutorial 7: Turning To A Shoulder

Getting Started In Machining - Absolute Beginners Click Here!

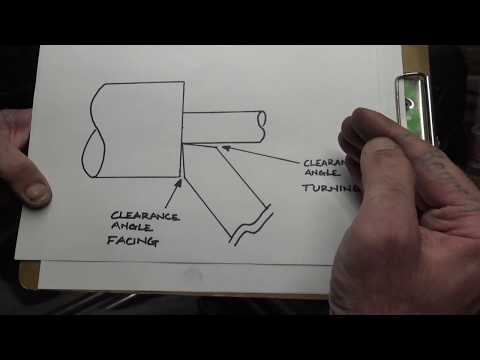

Metal Lathe Tutorial 2 : Tool Bits

Metal Lathe Operation, Practice and First Project

Metal Lathe Tutorial 12 : Surface Finish

Machinist Tips and Tricks Volume 1

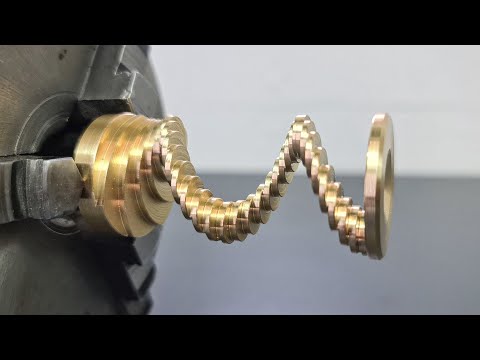

Making a Crazy Part on the Lathe - Manual Machining

Learning to Use a Lathe, Part 2: Turning Steel Down to Size

How to cut a thread on a manual lathe (Intermediate method ideal for home workshop & hobby engin...

Metal Lathe Tutorial 21 : Speeds & Feeds

Lathe Basics - WOOD magazine

Metal Lathe Tutorial 15: Parting

Lathe Machine : Definition, Parts, Types & Operations

Basic lathe work

Комментарии

0:07:22

0:07:22

0:15:21

0:15:21

0:09:32

0:09:32

0:18:36

0:18:36

0:02:03

0:02:03

0:18:32

0:18:32

0:00:30

0:00:30

0:02:16

0:02:16

0:04:27

0:04:27

0:05:03

0:05:03

0:08:01

0:08:01

0:28:21

0:28:21

0:07:21

0:07:21

0:55:00

0:55:00

0:19:07

0:19:07

0:05:15

0:05:15

0:04:15

0:04:15

0:18:58

0:18:58

0:12:07

0:12:07

0:21:20

0:21:20

0:12:33

0:12:33

0:30:57

0:30:57

0:04:32

0:04:32

0:10:12

0:10:12