filmov

tv

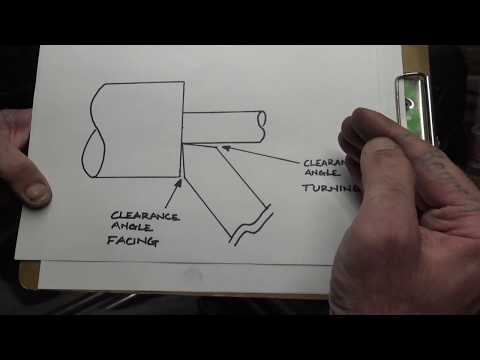

Metal Lathe Tutorial 1 : Theory

Показать описание

This is Lathe Skills, a multi-part series to help you learn basic machine shop work. Please support this work on Patreon:

Watch the whole Lathe Skills series at

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

For more cool shop projects, check out

Watch the whole Lathe Skills series at

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

For more cool shop projects, check out

Metal Lathe Tutorial 1 : Theory

Learning to Use a Lathe, Part 1: Basic operation and facing cut

Metal Lathe Tutorial 16: Your First Project!

Metal Lathe Tutorial 2 : Tool Bits

Metal Lathe Tutorial 3: Facing

Metal Lathe Tutorial 7: Turning To A Shoulder

Metal Lathe Tutorial 4: Tail Support

Metal Lathe Tutorial 6: Chatter

How to add Metal to your wood carving

Metal Lathe Tutorial 22 : Boring! Boring BARS, that is!

Metal Lathe Tutorial 8: Concentricity

Metal Lathe Tutorial 13 : How To Pick Metal

Metal Lathe Tutorial 21 : Speeds & Feeds

Metal Lathe Tutorial 12 : Surface Finish

Metal Lathe Tutorial 5: Turning

Metal Lathe Tutorial 15: Parting

Metal Lathe Basics Tutorial | How To Use A Metal Lathe

Metal Lathe Tutorial 18 : Your Second Project!

Metal Lathe Tutorial 9 : Four-Jaw Chucks

Metal Lathe Tutorial 10: Drilling

Metal Lathe Tutorial 20 : Snap Gauges & Depth Gauges

Lathe Tutorial P1 Machine Overview

Lathe Tutorial

Metal Lathe Tutorial 19 : Calipers & Micrometers

Комментарии

0:07:22

0:07:22

0:18:36

0:18:36

0:24:18

0:24:18

0:07:21

0:07:21

0:07:23

0:07:23

0:08:01

0:08:01

0:06:58

0:06:58

0:05:18

0:05:18

0:15:42

0:15:42

0:23:47

0:23:47

0:09:17

0:09:17

0:16:07

0:16:07

0:21:20

0:21:20

0:19:07

0:19:07

0:08:03

0:08:03

0:30:57

0:30:57

0:15:21

0:15:21

0:14:23

0:14:23

0:10:19

0:10:19

0:11:32

0:11:32

0:10:15

0:10:15

0:08:17

0:08:17

0:09:48

0:09:48

0:24:21

0:24:21