filmov

tv

How to fix and splice large battery cables and wires using solder and crimp

Показать описание

Simple way to make a permanent splice without removing cable.

Copper terminal

Solder

Dielectric grease

plastic zip ties

black electrical tape

Copper terminal

Solder

Dielectric grease

plastic zip ties

black electrical tape

6 Ways to Fix Broken Wires - Beginner Through Pro

How To Connect or Splice Wires Together - 10 Methods

How to splice wires - how to solder, how to crimp, wire connectors

Let's talk about the Splice problem 😬

How to Terminate Optic Fibre the Easy Way including my 3 tips. SC Connector and splice.

3 Ways to CORRECTLY Splice Electrical Wires

How To Repair A Damaged Electrical Cord Safely

How to fix and splice large battery cables and wires using solder and crimp

Easy Subarray Sum | P3149 | Codechef STARTERS 149 | Full Solution with code

How To Repair Splice Or Tap Into Stranded Copper Electrical Wires!

How to Fix an Open Splice in Under 2 minutes

How to Splice Wires Quickly and Correctly

How to fix Splice app not working

⚡️How to repair a 12/3 romex with an electrical splice kit😂 #whackhack #wkhk #thebasementking

How-To Install a Optical Fiber Splice-On Connector with ANY Fusion Splicer

How to Splice Wires Together in Your Car

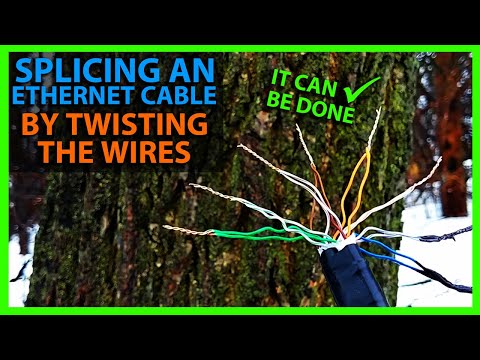

How To Splice an Ethernet Cable By Twisting The Wires Together

How to Fix Cassette Tapes The Right Way. Open, Splice, Repair Like a Pro.

Fix cut phone wire. Splice method no parts needed Like old timers

Making an Underground Electrical Splice

Run-ons and comma splices | Syntax | Khan Academy

Beginner Friendly Splicing - How To Splice 3 Stranded Rope Together

The solution to my Splice problem on my MPC. No Seriously , it's fixed now.

How To Fix A Cut Coaxial Cable-F Connector Repair Tutorial

Комментарии

0:13:27

0:13:27

0:06:38

0:06:38

0:10:01

0:10:01

0:14:41

0:14:41

0:07:48

0:07:48

0:14:22

0:14:22

0:07:06

0:07:06

0:02:46

0:02:46

0:11:10

0:11:10

0:08:36

0:08:36

0:00:51

0:00:51

0:09:10

0:09:10

0:01:02

0:01:02

0:01:04

0:01:04

0:06:12

0:06:12

0:03:38

0:03:38

0:07:51

0:07:51

0:36:21

0:36:21

0:05:18

0:05:18

0:03:56

0:03:56

0:04:38

0:04:38

0:09:01

0:09:01

0:05:01

0:05:01

0:03:39

0:03:39