filmov

tv

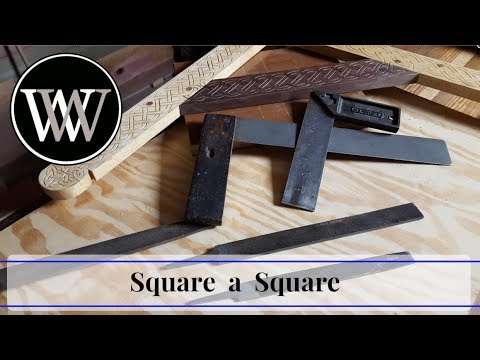

Make your own try-squares for woodwork.

Показать описание

New tools in this video (affiliate):

Follow me on Instagram: @rexkrueger

Make your own try-squares for woodwork.

Making shop squares

Make your own Try and Metre Squares | 3 min crafts

How to Square a Square and Make it True | Hand Tool Woodworking tip

Making Try squares

Making Squares for Woodworking

All about squares for woodworking.

French/Try Squares are back for 2019

Combination vs Double vs Try squares- Choosing the right one

Scrap Wood Try Squares

How to use sock to get unstuck #shorts

SHE PULLED THE SWORD OUT OF THE STONE RIGHT IN FRONT OF ME IN DISNEY WORLD

We Ate the Squares

How to do a TIKTOK Color Picking Trick in PROCREATE #Shorts

Straight Edges, Steel Rules, & Try Squares - The Archive Collection

2-Ingredient Truffles! tutorial #Shorts

SQUARES - Want to try this? See video description

Vintage Try Squares Restoration

I BUILT The *BEST* HOMEMADE Controller… (KontrolFreeks, Grips, + MORE!)

Everything you can do with Combo/T-Squares and Why they are the Most Important Tool in ANY Shop

How to Cut SQUARE Like a PRO!

If You See Square Waves, Get Out of the Water!

I Am Going To Read Your Mind - Part 2

DIY Welding Clamp Squares - Beginner Project - Forme Industrious

Комментарии

0:19:30

0:19:30

0:05:19

0:05:19

0:03:23

0:03:23

0:09:26

0:09:26

0:00:29

0:00:29

0:09:00

0:09:00

0:13:42

0:13:42

0:03:30

0:03:30

0:03:52

0:03:52

0:07:57

0:07:57

0:00:59

0:00:59

0:00:41

0:00:41

0:12:43

0:12:43

0:00:54

0:00:54

0:06:46

0:06:46

0:00:23

0:00:23

0:00:56

0:00:56

0:12:13

0:12:13

0:08:01

0:08:01

0:13:08

0:13:08

0:09:57

0:09:57

0:09:31

0:09:31

0:07:22

0:07:22

0:16:03

0:16:03