filmov

tv

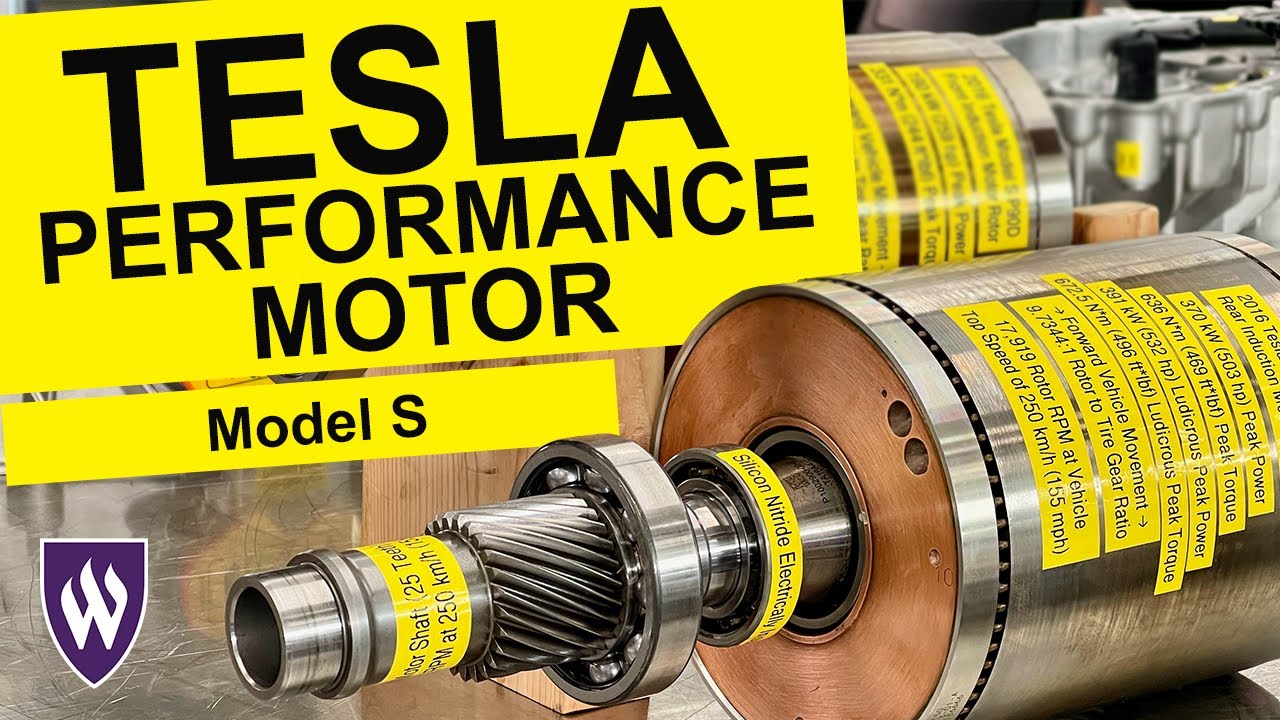

Understanding the Tesla Model S Performance Motor

Показать описание

Join me for a deep dive into the details of the 18,000 RPM performance rear motor and drive unit from a 2015-2016 Tesla Model S P90D. This drive unit is similar to the one used in the 2017-2020 P100D. The video is divided into four sections showing: 1. The motor and gears. 2. The high-performance bearings. 3. The lubrication system. and 4. The cooling system.

CORRECTIONS:

Thank you to everyone for catching my errors. There are always errors ;)

1. The Nissan Leaf ring gear is held on with 8 bolts, not 6.

2. The fluid in this drive unit is Dexron 6 transmission fluid.

3. Induction motor rotors do not have poles, just the stator. The 60 slot stator has four poles.

4. Silicon Nitride is a ceramic material.

TIMELINE:

0:00 Start

0:10 Introduction

1:35 Gearbox housing

2:10 Video Section 1 - Gears and Motor Rotor

2:45 The giant differential ring gear with 16-bolts!

4:20 The giant differential case bearings

4:50 The differential case speed at 250 km/h (155 mph) = 1841 RPM

5:15 MUST SEE Comparing the Tesla 213mm x 50mm. ring gear with 78 teeth (Factors 2, 3, 13) to a Chevrolet Bolt EV and Nissan Leaf EV

5:40 A Chevrolet Bolt EV differential 198mm x 34.3mm ring gear with 12-bolts.

6:10 A Nissan Leaf EV differential 200mm x 32mm ring gear with 8-bolts!

7:30 The Counter Shaft (Jack Shaft) with 25 (Factors 5, 5) pinion gear teeth. 78/25 = 3.12:1 Gear ratio from countershaft to the differential case

8:50 The countershaft speed at 250 km/h (155 mph) = 5743 RPM

9:30 The motor shaft with 25 teeth drives 78 teeth on the countershaft for another gear reduction of 78/25 = 3.12:1

10:08 The motor shaft speed at 250 km/h (155 mph) = 17,919 RPM

11:20 See all three gears in the reduction gearbox with an overall gear reduction of (78/25) x (78/25) = 9.7344:1

12:05 MUST SEE The AC Induction Motor Rotor with 74 bars

13:25 Motor specifications for power, torque, and gear ratio

16:22 MUST SEE Close up view of silicon nitride bearing

18:20 The motor rotor speed sensor reluctor wheel (tone ring)

19:22 Must SEE The rotor installed on the drive gear and the functioning gearbox

20:18 Video Section 2 - Specialized Bearings

21:21 The 60 slot four-pole stator and housing

23:05 The oil pump and how it is overdriven by the differential ring gear 23/78 = 0.2948:1 gear ratio (3.339 times faster than the ring gear)

23:55 MUST SEE The function of the oil pump (it may surprise you)

26:27 Motor shaft (Input Shaft) bearing reference speed and limiting speeds

27:30 How to run bearings at higher speeds than their limiting speeds

29:54 Video Section 3 - Lubrication

30:25 Drain and fill plug locations

30:50 Gearbox vent and inverter vents

31:05 Sport model label

31:39 MUST SEE Four different sealed areas in the drive unit

32:46 Video Section 4 - Cooling System

33:30 MUST SEE The coolant inlet port and the two paths coolant takes

33:53 Up for rotor cooling and gearbox cooling

35:03 Down for stator and inverter cooling

36:05 Coolant from the rotor moves to the gearbox heat exchanger and the outlet port

37:25 Stator temperature sensors

38:10 Coolant from the stator to the inverter coolant passages

38:28 Stator coolant temperature sensor

38:35 MUST SEE Insulated-Gate Bi-Polar Transistor (IGBT) module coolant passages and flow through gearbox passages

40:34 Inverter coolant outlet temperature sensor

40:45 The gearbox oil-to-coolant heat exchanger

41:38 Coolant outlet port to coolant pump and onboard charger module under the back seat.

41:55 Drive unit cooling system summary

43:04 IGBT inverter modules installed and inverter cover

43:40 High voltage battery cable connections and low voltage connections at the inverter

44:35 Video summary

ABOUT US

ADDITIONAL TRAINING FOR YOU

DONATE TO OUR DEPARTMENT

CORRECTIONS:

Thank you to everyone for catching my errors. There are always errors ;)

1. The Nissan Leaf ring gear is held on with 8 bolts, not 6.

2. The fluid in this drive unit is Dexron 6 transmission fluid.

3. Induction motor rotors do not have poles, just the stator. The 60 slot stator has four poles.

4. Silicon Nitride is a ceramic material.

TIMELINE:

0:00 Start

0:10 Introduction

1:35 Gearbox housing

2:10 Video Section 1 - Gears and Motor Rotor

2:45 The giant differential ring gear with 16-bolts!

4:20 The giant differential case bearings

4:50 The differential case speed at 250 km/h (155 mph) = 1841 RPM

5:15 MUST SEE Comparing the Tesla 213mm x 50mm. ring gear with 78 teeth (Factors 2, 3, 13) to a Chevrolet Bolt EV and Nissan Leaf EV

5:40 A Chevrolet Bolt EV differential 198mm x 34.3mm ring gear with 12-bolts.

6:10 A Nissan Leaf EV differential 200mm x 32mm ring gear with 8-bolts!

7:30 The Counter Shaft (Jack Shaft) with 25 (Factors 5, 5) pinion gear teeth. 78/25 = 3.12:1 Gear ratio from countershaft to the differential case

8:50 The countershaft speed at 250 km/h (155 mph) = 5743 RPM

9:30 The motor shaft with 25 teeth drives 78 teeth on the countershaft for another gear reduction of 78/25 = 3.12:1

10:08 The motor shaft speed at 250 km/h (155 mph) = 17,919 RPM

11:20 See all three gears in the reduction gearbox with an overall gear reduction of (78/25) x (78/25) = 9.7344:1

12:05 MUST SEE The AC Induction Motor Rotor with 74 bars

13:25 Motor specifications for power, torque, and gear ratio

16:22 MUST SEE Close up view of silicon nitride bearing

18:20 The motor rotor speed sensor reluctor wheel (tone ring)

19:22 Must SEE The rotor installed on the drive gear and the functioning gearbox

20:18 Video Section 2 - Specialized Bearings

21:21 The 60 slot four-pole stator and housing

23:05 The oil pump and how it is overdriven by the differential ring gear 23/78 = 0.2948:1 gear ratio (3.339 times faster than the ring gear)

23:55 MUST SEE The function of the oil pump (it may surprise you)

26:27 Motor shaft (Input Shaft) bearing reference speed and limiting speeds

27:30 How to run bearings at higher speeds than their limiting speeds

29:54 Video Section 3 - Lubrication

30:25 Drain and fill plug locations

30:50 Gearbox vent and inverter vents

31:05 Sport model label

31:39 MUST SEE Four different sealed areas in the drive unit

32:46 Video Section 4 - Cooling System

33:30 MUST SEE The coolant inlet port and the two paths coolant takes

33:53 Up for rotor cooling and gearbox cooling

35:03 Down for stator and inverter cooling

36:05 Coolant from the rotor moves to the gearbox heat exchanger and the outlet port

37:25 Stator temperature sensors

38:10 Coolant from the stator to the inverter coolant passages

38:28 Stator coolant temperature sensor

38:35 MUST SEE Insulated-Gate Bi-Polar Transistor (IGBT) module coolant passages and flow through gearbox passages

40:34 Inverter coolant outlet temperature sensor

40:45 The gearbox oil-to-coolant heat exchanger

41:38 Coolant outlet port to coolant pump and onboard charger module under the back seat.

41:55 Drive unit cooling system summary

43:04 IGBT inverter modules installed and inverter cover

43:40 High voltage battery cable connections and low voltage connections at the inverter

44:35 Video summary

ABOUT US

ADDITIONAL TRAINING FOR YOU

DONATE TO OUR DEPARTMENT

Комментарии

0:46:28

0:46:28

0:52:51

0:52:51

0:46:32

0:46:32

0:31:39

0:31:39

0:04:55

0:04:55

0:11:37

0:11:37

0:19:50

0:19:50

0:12:08

0:12:08

0:00:09

0:00:09

0:27:50

0:27:50

0:10:09

0:10:09

0:13:55

0:13:55

0:17:05

0:17:05

0:10:34

0:10:34

0:17:41

0:17:41

0:07:25

0:07:25

0:14:23

0:14:23

0:16:42

0:16:42

0:13:17

0:13:17

0:00:16

0:00:16

0:11:20

0:11:20

0:23:42

0:23:42

0:25:09

0:25:09

0:11:21

0:11:21