filmov

tv

How Square are My Squares? Testing 10 Different Squares from $3 to $140 Using an Easy & Free Test

Показать описание

Many of us have multiple ways to check material for square, but how square are our squares? In this video I'll testing 10 different layout, combination, and bench squares to see just how square they are and show you how to test yours.

CHAPTERS:

0:00 Introduction

0:14 Larger squares

2:39 How to test a square for square

3:35 Testing the larger squares

8:58 Testing the smaller square

11:18 Final thoughts

Please note that this video is not sponsored by any of the brands in the video and all products have been purchased with my own money.

#woodworkingsquares #woodpeckers #howsquare

CHAPTERS:

0:00 Introduction

0:14 Larger squares

2:39 How to test a square for square

3:35 Testing the larger squares

8:58 Testing the smaller square

11:18 Final thoughts

Please note that this video is not sponsored by any of the brands in the video and all products have been purchased with my own money.

#woodworkingsquares #woodpeckers #howsquare

How Square are My Squares? Testing 10 Different Squares from $3 to $140 Using an Easy & Free Tes...

All about squares for woodworking.

Check your squares for square!

Squares go out of square. How to fix wood, plastic, and metal squares.

All about SQUARES in Astrology | Astrology Basics | How to handle SQUARES 🔥

Make your own try-squares for woodwork.

Making Squares for Woodworking

Adding more squares to my scrap yarn blanket 💕 #crochetart #crochet

How to crochet a hat / beanie with diamond granny squares super easy follow along tutorial

Just how square were the old classic Starrett combination squares anyway?

What can you make with just 4 Granny Squares?

Tool Storage Ideas DIY - Storing Squares

Learn All About Squares! 🟨 Shape Songs with the StoryBots | Netflix Jr

EASY GRANNY SQUARE COLOR CHANGES + 5 Expert Tips for Flawless Squares

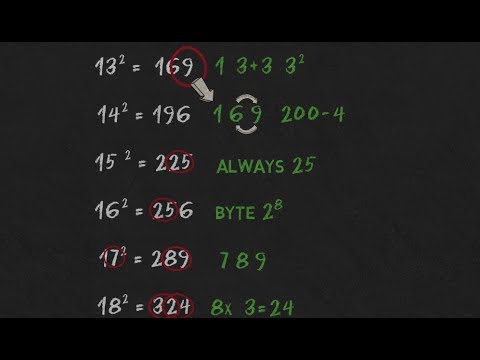

Memorizing Squares by Association - First 25 - Quick Mental Math Trick

Summing Squares Geometrically

Everything you can do with Combo/T-Squares and Why they are the Most Important Tool in ANY Shop

Cutting Perfect Fabric Squares and Rectangles

'Squares,' Songs About Shapes by StoryBots | Netflix Jr

How To Easily Sew Crochet Granny Squares

How to Join Granny Squares with Invisible Seam

We Ate the Squares

The Easiest and Fastest Way to Join Granny Squares!

07 - Factoring Perfect Square Trinomials & Factoring the Difference of Two Squares

Комментарии

0:13:35

0:13:35

0:13:42

0:13:42

0:01:00

0:01:00

0:23:20

0:23:20

0:05:16

0:05:16

0:19:30

0:19:30

0:09:00

0:09:00

0:00:18

0:00:18

0:18:58

0:18:58

0:04:51

0:04:51

0:00:15

0:00:15

0:07:41

0:07:41

0:02:34

0:02:34

0:17:10

0:17:10

0:04:15

0:04:15

0:00:56

0:00:56

0:13:08

0:13:08

0:08:32

0:08:32

0:01:24

0:01:24

0:13:34

0:13:34

0:05:11

0:05:11

0:12:43

0:12:43

0:04:32

0:04:32

0:27:38

0:27:38