filmov

tv

Ghosting in 3D Prints - What is it and how do you fix it?

Показать описание

Ghosting artifacts can really ruin the look of a 3D Printed object! In this video we'll discuss what ghosting (or ringing, rippling, echoing) is and how you can reduce or eliminate it from your 3D Printed models.

Support Maker's Muse on Patreon

Support Maker's Muse on Patreon

Ghosting in 3D Prints - What is it and how do you fix it?

Reduce Ghosting for a Dollar - 3D Printing

Reducing 3d Printing Ghosting

Remove ringing by tuning acceleration and junction deviation - step by step guide

We solved this common problem in 3D printing

Four ways to beat moire on your 3D printer

What 3D Printing Ghosting Looks Like & How I fixed it in 4 easy steps?

Ultimate 3D Print RINGING Tests | Remove Longer LK5 Pro GHOSTING

THIS IS Y

POCKMARKS - how to get rid of gaps in 3D prints

(HOW) I fixed the Ugly Layers on my 3D Printer

KingRoon Easy Fix for wavey/ghosting prints

CR10S ghosting fix

Wobbly 3D printer makes for better parts!

Creality Ender 3 V2 - Simple Tips for Super Clean 3D Prints

How a 3DBenchy can tell where your 3D prints need improvement

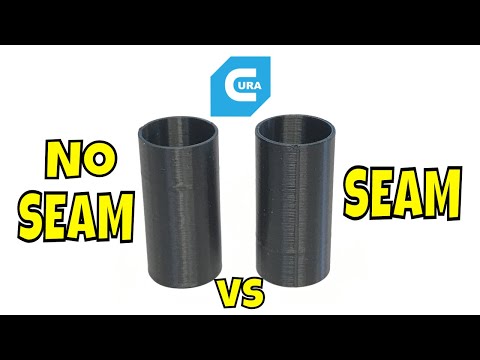

How to Control Seams In Cura Slicer Settings

Fix Ringing & Ghosting on Creality K1 3D Printer #shorts

We found the BEST belt tension for 3D printers

Issues with ghosting in your #3dprints. Try using a STEP file. #3dprinting #engineering #design

This setting might actually be ruining your prints, instead of helping them.

Ghosting, banding, and general print quality issues fixed! Z axis

Arduino Keypad - Branding Ghosting Problem - 3D Print

3D Printer Wall Anchor - ROCK SOLID upgrade! (Reduce Vibration/Ghosting)

Комментарии

0:05:50

0:05:50

0:04:37

0:04:37

0:12:29

0:12:29

0:17:19

0:17:19

0:04:53

0:04:53

0:08:16

0:08:16

0:06:41

0:06:41

0:07:18

0:07:18

0:12:02

0:12:02

0:03:10

0:03:10

0:10:50

0:10:50

0:04:56

0:04:56

0:08:57

0:08:57

0:12:52

0:12:52

0:08:26

0:08:26

0:12:23

0:12:23

0:06:58

0:06:58

0:00:23

0:00:23

0:11:41

0:11:41

0:01:01

0:01:01

0:14:28

0:14:28

0:01:08

0:01:08

0:00:57

0:00:57

0:01:25

0:01:25