filmov

tv

$430 Gadget Fixed for 50 cents with 3D Printing

Показать описание

THINGS I USED IN THIS VIDEO:

OTHER TOOLS I LIKE TO USE:

Note: The above shopping links are affiliate links, meaning that, at no additional cost to you, I may earn a commission if you click through and make a purchase.

TRACK LISTING:

Urban Conspiracy - Jules Gaia

Singularity - Lagua Vesa

Nemesis - Alec Slayne

12th Floor Party - Jules Gaia

The Rhythm Recipe - Jules Gaia

B.O.D. - Heyson

Slippin' Away - El Flaco Collective

Displaced - Robert Ruth

Merry Had a Little Christmas - Jobii

Blow - Duckmaw

Middle - Jones Meadow

Wood - Pableno

Ghosting - Christopher Moe Ditlevsen

Acid House - VELDA

See Em' Dancing - Jones Meadow

Cafe Bossa - Riverworm

Lit - Jones Meadow

#3Dprinting #functionalprint #technology

$430 Gadget Fixed for 50 cents with 3D Printing

Wood Saw Machine Tool #Gadget #Gadgets 😉SUBSCRIBE PLEASE!👇👇👇 #shorts

Is FIXD RIPPING you off? FIXD APP Q&A

Best OBD2 Scanner 2024 [don’t buy one before watching this]

Garmin Astro 430 Product Overview

This Scan Tool Destroyed My Car and I'm Mad as Hell

Here's Why the BlueDriver OBD2 is the Best Scan Tool in the World

If You Have $2,800, Buy This Car and Double Your Money

Hidden screen on cars #gadgets #cars

How-To. Creating a BMW Digital Key Plus for iPhone

50 NEXT LEVEL Camping Gear & Gadgets In 2024

7 Pens That Do More Than Write

This Antenna Increased My Radio's Range By A LOT!

Best Useful & Smart Gadgets for Daily uses ||iBall USB HUB|| #shorts #ytshorts #iball #usb

What No-one Tells You About ROOF BOXES (Why Roof Baskets are Better)

Setup/Pair BMW to Garage Door (2 Ways)

Mercedes Benz Key Fob Explanation How To DIY Learning Tutorials

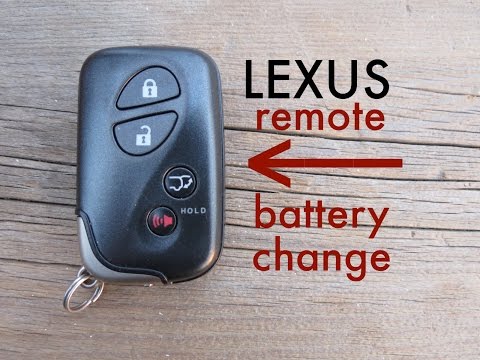

How to ● Lexus Key Fob Remote Keyless Battery Replace HS, ES, GS, LS, IS, GX, CT

SHOOTING 430 NERF DARTS AS FAST AS POSSIBLE #16 | Adventure Force V-Twin

Why Now is the BEST Time to Buy Yaesu

IROBOT ROOMBA NOT CHARGING! EASY FIX! 😎👍

how to use strapping tensioner & sealer tool

This EDC Gadget is worth it

Samsung Soundbar reset ARC not working fix

Комментарии

0:16:56

0:16:56

0:00:19

0:00:19

0:10:20

0:10:20

0:09:04

0:09:04

0:06:27

0:06:27

0:13:16

0:13:16

0:02:30

0:02:30

0:11:36

0:11:36

0:00:07

0:00:07

0:02:01

0:02:01

1:07:41

1:07:41

0:00:55

0:00:55

0:06:30

0:06:30

0:00:51

0:00:51

0:05:55

0:05:55

0:02:24

0:02:24

0:03:33

0:03:33

0:02:34

0:02:34

0:07:23

0:07:23

0:11:39

0:11:39

0:01:33

0:01:33

0:03:03

0:03:03

0:00:23

0:00:23

0:00:35

0:00:35