filmov

tv

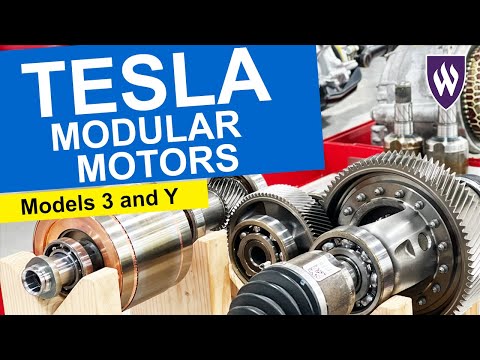

Tesla Model 3 and Y Modular Motors

Показать описание

Check out the modular components and design of the electric motors on the Tesla Models 3 and Y. See how many parts are common and interchangeable.

Corrections:

1. I swapped the definition of a Hunting gear set with a Non-Hunting gear set.

TIMELINE:

0:00 Introduction

0:27 The rear motor of the Model 3 and Y

1:08 The input shaft with 31 teeth (Prime Number)

2:00 the input shaft SKF bearings for a rotor speed of 18,447 at 262 km/h (163 mph)

2:40 The countershaft and gear with 81 teeth (Factors 3, 3, 3, 3)

3:00 The input shaft to the countershaft gear ratio of 81/31 = 2.6129:1

3:10 The countershaft pinion gear with 24 teeth (Factors 2, 2, 2, 3)

3:15 The ring gear and differential case with 83 teeth (Prime Number)

4:30 The countershaft to ring gear ratio of 83/24 = 3.4583:1

4:43 The overall gear ratio = (81/31) x (83/24) = 9.0363:1

5:03 The published gear ratio is incorrect. This is a Hunting Gearset

5:48 The CV half-shafts connect to the differential side gears

6:46 MUST SEE: two cool Permanent Magnet rotor demonstrations

8:05 The modular design of the motor shafts and rotors

8:25 MUST SEE: Watch as a rear motor is changed into a front motor

10:32 The differences in the modular motors

11:35 See what a permanent magnet does to the Induction Rotor

11:55 An aluminum core front induction rotor on the Model Y

12:13 There are at least three different rotors for the Models 3 and Y

13:54 See the rear motor inverter and where it attaches to the rear housing

14:45 The matching part numbers of the rear inverter and the stator (A matched set)

15:15 The three different power and torque levels of the Model 3 and Model Y

16:15 MUST SEE: See the front motor inverter attached to the rear housing!

17:37 the common bolt pattern and opening for the stator housings

18:30 The oil-cooled stator and ATF-9 fluid

18:47 The interchangeable transmission heat exchanger

19:13 The interchangeable variable speed electric oil pump

20:25 The interchangeable spin-on oil filter

21:06 What is not interchangeable between models

21:20 The rear drive-unit is mounted parallel with the ground

22:20 The front drive-unit is mounted upside down and on an angle

23:05 The matching part numbers of the front inverter and the stator (A matched set)

26:58 Video summary and donation opportunity

I have nothing to prove this, but while looking at used Model 3 motors for sale on eBay, I gathered the following information. There are three different part numbers for the combined rear motor inverters and stators. Stators can have different milli-ohm resistance values and still appear identical.

* 1120970-00-D (24 SiC IGBT modules Based RWD model 3)

* 1120980-00-C, D, F (24 SiC MOSFET modules Performance AWD model 3)

* 1120990-00-F (18 SiC MOSFET modules Non-Performance AWD model 3)

ABOUT US

Weber State University (WSU) Davis Campus - Automotive Technology Department - Advanced Vehicles Lab. A technical description and operational demonstration of the Tesla Model S Rear Drive Unit (RDU) and Fear Drive Unit (FDU).

ADDITIONAL TRAINING FOR YOU

DONATE TO OUR DEPARTMENT

QUESTIONS FOR TEACHERS

1.

Corrections:

1. I swapped the definition of a Hunting gear set with a Non-Hunting gear set.

TIMELINE:

0:00 Introduction

0:27 The rear motor of the Model 3 and Y

1:08 The input shaft with 31 teeth (Prime Number)

2:00 the input shaft SKF bearings for a rotor speed of 18,447 at 262 km/h (163 mph)

2:40 The countershaft and gear with 81 teeth (Factors 3, 3, 3, 3)

3:00 The input shaft to the countershaft gear ratio of 81/31 = 2.6129:1

3:10 The countershaft pinion gear with 24 teeth (Factors 2, 2, 2, 3)

3:15 The ring gear and differential case with 83 teeth (Prime Number)

4:30 The countershaft to ring gear ratio of 83/24 = 3.4583:1

4:43 The overall gear ratio = (81/31) x (83/24) = 9.0363:1

5:03 The published gear ratio is incorrect. This is a Hunting Gearset

5:48 The CV half-shafts connect to the differential side gears

6:46 MUST SEE: two cool Permanent Magnet rotor demonstrations

8:05 The modular design of the motor shafts and rotors

8:25 MUST SEE: Watch as a rear motor is changed into a front motor

10:32 The differences in the modular motors

11:35 See what a permanent magnet does to the Induction Rotor

11:55 An aluminum core front induction rotor on the Model Y

12:13 There are at least three different rotors for the Models 3 and Y

13:54 See the rear motor inverter and where it attaches to the rear housing

14:45 The matching part numbers of the rear inverter and the stator (A matched set)

15:15 The three different power and torque levels of the Model 3 and Model Y

16:15 MUST SEE: See the front motor inverter attached to the rear housing!

17:37 the common bolt pattern and opening for the stator housings

18:30 The oil-cooled stator and ATF-9 fluid

18:47 The interchangeable transmission heat exchanger

19:13 The interchangeable variable speed electric oil pump

20:25 The interchangeable spin-on oil filter

21:06 What is not interchangeable between models

21:20 The rear drive-unit is mounted parallel with the ground

22:20 The front drive-unit is mounted upside down and on an angle

23:05 The matching part numbers of the front inverter and the stator (A matched set)

26:58 Video summary and donation opportunity

I have nothing to prove this, but while looking at used Model 3 motors for sale on eBay, I gathered the following information. There are three different part numbers for the combined rear motor inverters and stators. Stators can have different milli-ohm resistance values and still appear identical.

* 1120970-00-D (24 SiC IGBT modules Based RWD model 3)

* 1120980-00-C, D, F (24 SiC MOSFET modules Performance AWD model 3)

* 1120990-00-F (18 SiC MOSFET modules Non-Performance AWD model 3)

ABOUT US

Weber State University (WSU) Davis Campus - Automotive Technology Department - Advanced Vehicles Lab. A technical description and operational demonstration of the Tesla Model S Rear Drive Unit (RDU) and Fear Drive Unit (FDU).

ADDITIONAL TRAINING FOR YOU

DONATE TO OUR DEPARTMENT

QUESTIONS FOR TEACHERS

1.

Комментарии

0:09:34

0:09:34

0:09:56

0:09:56

0:21:24

0:21:24

0:09:45

0:09:45

0:14:29

0:14:29

0:21:32

0:21:32

0:04:55

0:04:55

0:43:23

0:43:23

0:00:48

0:00:48

0:06:28

0:06:28

0:06:41

0:06:41

0:21:32

0:21:32

0:16:18

0:16:18

0:12:33

0:12:33

0:10:15

0:10:15

0:10:02

0:10:02

0:13:55

0:13:55

0:23:37

0:23:37

0:19:08

0:19:08

0:27:57

0:27:57

0:12:25

0:12:25

0:09:40

0:09:40

0:10:20

0:10:20

0:12:49

0:12:49