filmov

tv

How a Two Stroke Carburetor Works

Показать описание

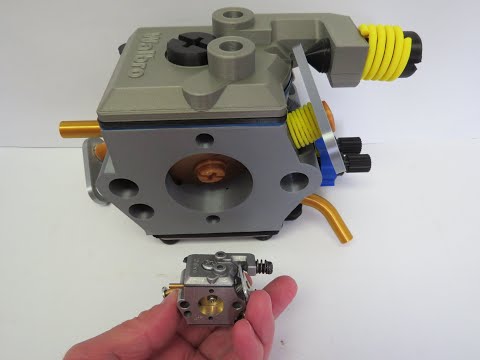

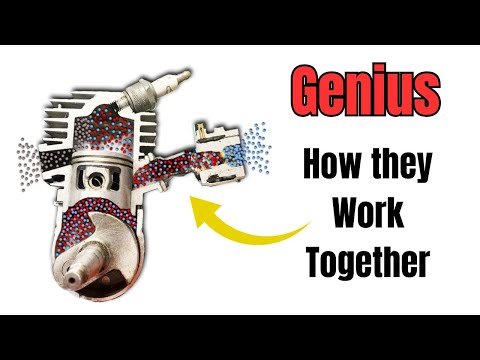

A small two-stroke chainsaw carburetor is a crucial component responsible for delivering the right mixture of air and fuel to the engine for efficient combustion. Let's delve into the various parts and how they work together:

Fuel Pump Diaphragm: The fuel pump diaphragm is frequently the first part of the fuel circuit of a carburetor. It works by using pressure variations caused by engine pulses. A vacuum is created in the crankcase as the engine operates. By flexing the fuel pump diaphragm as a result of the vacuum action, fuel is drawn from the fuel tank into the carburetor and into the metering chamber.

Impulse Line: The engine's carburetor is connected to the crankcase by the impulse line. It transports crankcase pressure pulses to the carburetor. The fuel pump diaphragm uses these pressure pulses to help pump fuel into the metering chamber.

Metering Diaphragm: An essential component of the carburetor is the metering diaphragm. By reacting to variations in air pressure, it controls the amount of gasoline that is injected into the engine. The metering diaphragm flexes as a result of air flowing through the carburetor when the engine is running. By altering the fuel flow through the carburetor's jets, this movement can change the air-fuel ratio to suit a range of engine loads and speeds.

Screen Filter: The screen filter is positioned inside the carburetor's fuel inlet. By keeping dirt and debris out, the carburetor's internal parts are kept clear of blockage. For a carburetor to function properly, the filter must be clean.

The high-speed screw and the low-speed screw are the two adjustable screws that are commonly present in small two-stroke chainsaw carburetors. The air-fuel mixture can be adjusted with these screws at both high and low engine speeds. These screws can be turned clockwise or anticlockwise to lean out the mixture or enrich it.

Fuel Holes: The carburetor's body's fuel holes and jets regulate the fuel's passage through the device. To guarantee the proper air-fuel ratio under varied engine running situations, these holes are properly sized and positioned.

The metering diaphragm reacts to changes in pressure as the engine runs and air is pulled through the carburetor, adjusting the fuel flow as necessary. In order to maintain a constant flow of gasoline, the fuel pump's impulse line, pressure pulses from the crankcase and diaphragm all work together. For optimum engine efficiency, the adjuster screws provide you the opportunity to fine-tune the mixture. The correct air-fuel ratio is delivered to the engine by these parts collectively, enabling the chainsaw to run smoothly and effectively.

I hope you gain something from this video

Thank you

Craig Kirkman (Owner and Creator of The Repair Specialist Channel)

#ChainawCarburetor

#FuelPumpDiaphragm

#ImpulseLine

#MeteringDiaphragm

#ScreenFilter

#CarburetorComponents

#CarburetorParts

#AdjusterScrews

#FuelHoles

#TwoStrokeEngine

#EngineCombustion

#CarburetorTuning

#SmallEngineMaintenance

#AirFuelMixture

#CarburetorFunction

#FuelDelivery

#EnginePerformance

#CarburetorTechnology

#EfficientCombustion

#EngineEfficiency

Комментарии

0:21:45

0:21:45

0:09:22

0:09:22

0:19:22

0:19:22

0:09:21

0:09:21

0:27:31

0:27:31

0:03:58

0:03:58

0:14:16

0:14:16

0:09:48

0:09:48

0:01:53

0:01:53

0:10:18

0:10:18

0:04:36

0:04:36

0:08:31

0:08:31

0:10:58

0:10:58

0:00:25

0:00:25

0:08:03

0:08:03

0:07:52

0:07:52

0:09:04

0:09:04

0:15:47

0:15:47

0:05:56

0:05:56

0:04:35

0:04:35

0:04:44

0:04:44

0:06:52

0:06:52

0:14:33

0:14:33

0:06:35

0:06:35