filmov

tv

How the 2-Stroke Engine & Carburetor Work Together!

Показать описание

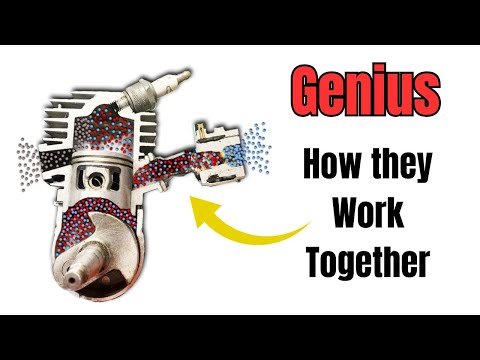

An Enlightening Explanation of how the Engine & Carb work as One. FOR GREATER KNOWLEDGE

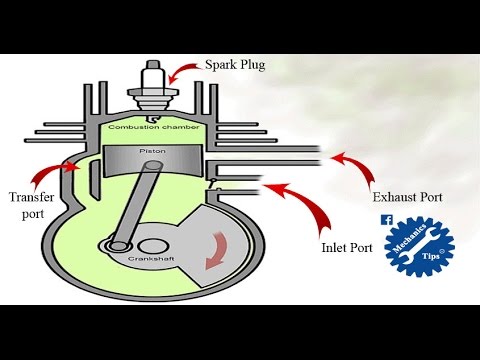

- So let's begin: An internal combustion engine known as a two-stroke engine runs on a special cycle that requires two piston strokes (up and down) to complete one cycle of operation. Due to its simplicity and lightweight attributes, this design is frequently employed in smaller power equipment like chainsaws, motorbikes, and outboard boat engines. A two-stroke engine operates as follows:

The piston begins its downward movement during the intake stroke when it is at the top of the cylinder, close to the spark plug. It uncovers ports or apertures near the cylinder bottom that are connected to the crankcase (lower part of the engine) as it descends. In the cylinder, the piston's downward action partially evacuates the space.

Air-Fuel Mixture Intake: As the piston descends, a mixture of air and fuel (typically premixed) is taken into the cylinder from the carburetor or the fuel injection system. Then, through the open ports, this mixture is drawn into the crankcase.

Compression Stroke (Upward Movement): After the piston completes its downward stroke, it turns around and ascends the cylinder in the opposite direction. The air-fuel combination pumped into the crankcase during the intake stroke is compressed as it rises. Near the apex of the stroke, the spark plug ignites this compressed mixture.

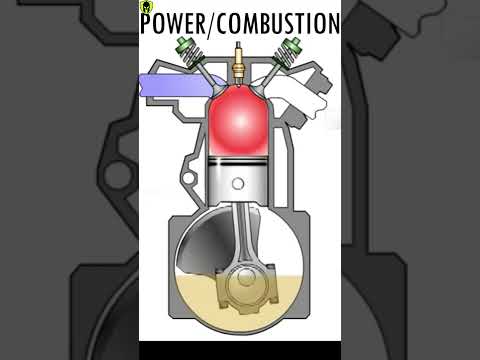

Power Stroke: As the compressed combination burns, a high-pressure, expanding gas is created. Mechanical work is produced as a result of the expanding gas pushing the piston down the cylinder. This is the engine's power stroke.

Exhaust Stroke (Upward Movement): The piston resumes its upward motion after the power stroke. Near the top of the cylinder, it reveals exhaust openings as it rises. Through these exhaust ports, the expanding gas from the power stroke is discharged into the exhaust system.

The cycle is repeated, and the engine keeps running as a result. At the end of the exhaust stroke, when the piston has reached the top of the cylinder, the intake ports are once more exposed, and the cycle repeats. A power stroke occurs after every two piston strokes (one full up-and-down movement) in a two-stroke engine.

Two-stroke engines are notable for their simplicity and light weight, making them appropriate for applications where compactness and strong power-to-weight ratios are crucial. However, in comparison to four-stroke engines, which have an independent intake and exhaust stroke, they also frequently use less gasoline and sometimes emit more pollution. Additionally, two-stroke engines frequently need their fuel and oil mixed together in order to lubricate the moving parts.

This principle works for most types of Chainsaw saws, and the following also helps with Chainsaw maintenance. So, whether you are using a Stihl Chainsaw, Husquvarna Chainsaw, basically, all types of Petrol Chainsaw are valid for this principle, as well as many types of or a 2 Stroke Engine. The Electric Chainsaw, of course, escapes this whole principle!

I really hope you enjoy. Craig

Many thanks

#TwoStrokeEngine

#InternalCombustion

#EngineCycle

#PowerEquipment

#MechanicalEngineering

#TwoStrokeTechnology

#EngineBasics

#SmallEngine

#EngineOperation

#EngineCycleExplained

#TwoStrokePower

#AirFuelMixture

#CompressionStroke

#PowerStroke

#ExhaustStroke

#TwoStrokeDesign

#TwoStrokeAdvantages

#EngineMaintenance

#PowerGeneration

#EngineEfficiency

The creation of information in this description was helped by ChatGPT

- So let's begin: An internal combustion engine known as a two-stroke engine runs on a special cycle that requires two piston strokes (up and down) to complete one cycle of operation. Due to its simplicity and lightweight attributes, this design is frequently employed in smaller power equipment like chainsaws, motorbikes, and outboard boat engines. A two-stroke engine operates as follows:

The piston begins its downward movement during the intake stroke when it is at the top of the cylinder, close to the spark plug. It uncovers ports or apertures near the cylinder bottom that are connected to the crankcase (lower part of the engine) as it descends. In the cylinder, the piston's downward action partially evacuates the space.

Air-Fuel Mixture Intake: As the piston descends, a mixture of air and fuel (typically premixed) is taken into the cylinder from the carburetor or the fuel injection system. Then, through the open ports, this mixture is drawn into the crankcase.

Compression Stroke (Upward Movement): After the piston completes its downward stroke, it turns around and ascends the cylinder in the opposite direction. The air-fuel combination pumped into the crankcase during the intake stroke is compressed as it rises. Near the apex of the stroke, the spark plug ignites this compressed mixture.

Power Stroke: As the compressed combination burns, a high-pressure, expanding gas is created. Mechanical work is produced as a result of the expanding gas pushing the piston down the cylinder. This is the engine's power stroke.

Exhaust Stroke (Upward Movement): The piston resumes its upward motion after the power stroke. Near the top of the cylinder, it reveals exhaust openings as it rises. Through these exhaust ports, the expanding gas from the power stroke is discharged into the exhaust system.

The cycle is repeated, and the engine keeps running as a result. At the end of the exhaust stroke, when the piston has reached the top of the cylinder, the intake ports are once more exposed, and the cycle repeats. A power stroke occurs after every two piston strokes (one full up-and-down movement) in a two-stroke engine.

Two-stroke engines are notable for their simplicity and light weight, making them appropriate for applications where compactness and strong power-to-weight ratios are crucial. However, in comparison to four-stroke engines, which have an independent intake and exhaust stroke, they also frequently use less gasoline and sometimes emit more pollution. Additionally, two-stroke engines frequently need their fuel and oil mixed together in order to lubricate the moving parts.

This principle works for most types of Chainsaw saws, and the following also helps with Chainsaw maintenance. So, whether you are using a Stihl Chainsaw, Husquvarna Chainsaw, basically, all types of Petrol Chainsaw are valid for this principle, as well as many types of or a 2 Stroke Engine. The Electric Chainsaw, of course, escapes this whole principle!

I really hope you enjoy. Craig

Many thanks

#TwoStrokeEngine

#InternalCombustion

#EngineCycle

#PowerEquipment

#MechanicalEngineering

#TwoStrokeTechnology

#EngineBasics

#SmallEngine

#EngineOperation

#EngineCycleExplained

#TwoStrokePower

#AirFuelMixture

#CompressionStroke

#PowerStroke

#ExhaustStroke

#TwoStrokeDesign

#TwoStrokeAdvantages

#EngineMaintenance

#PowerGeneration

#EngineEfficiency

The creation of information in this description was helped by ChatGPT

Комментарии

0:02:12

0:02:12

0:00:21

0:00:21

0:12:01

0:12:01

0:03:27

0:03:27

0:05:05

0:05:05

0:04:59

0:04:59

0:09:57

0:09:57

0:04:26

0:04:26

0:01:03

0:01:03

0:04:38

0:04:38

0:27:22

0:27:22

0:09:22

0:09:22

0:00:23

0:00:23

0:13:25

0:13:25

0:02:02

0:02:02

0:12:22

0:12:22

0:19:51

0:19:51

0:07:19

0:07:19

0:01:01

0:01:01

0:00:57

0:00:57

![[HINDI] How 2](https://i.ytimg.com/vi/Kk8B-jLx_8M/hqdefault.jpg) 0:03:53

0:03:53

0:04:44

0:04:44

0:02:27

0:02:27

0:03:43

0:03:43