filmov

tv

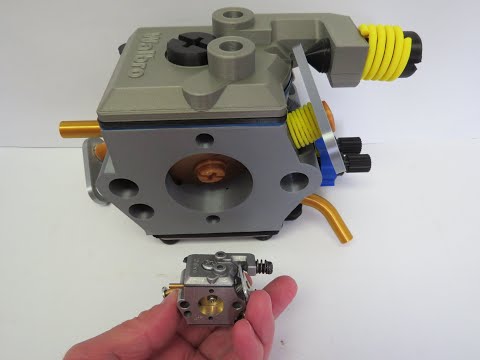

Two Stroke Chainsaw Carburetor 'Impulse/Pulse Line (How it Works!) (by Craig Kirkman)

Показать описание

* VISUALLY EXPLAINED

An issue often overlooked when a 2 stroke engine fails, such as when a Chainsaw Won't Start, is the Pulse Line. Exclusive to the two stroke engine, the Pulse Line is responsible for carrying air pressures from the engine into the carburetor and operate the fuel pump diaphragm.

If the pulse line is damaged (leaking) then the vital pressure cannot be carried to the fuel pump diaphragm resulting in the pump not working. The obvious effects of which is that no fuel can the carburetor's main jet to supply the engine. This results in engine failure.

The impulse line in a chainsaw engine plays a crucial role in the proper functioning of the carburetor. Its primary function is to create pressure pulses that help operate the fuel pump diaphragm within the carburetor. Here's how it works:

Pressure Pulses: The impulse line is connected to the engine's crankcase. As the engine runs, it generates pressure pulses in the crankcase due to the movement of the piston. These pressure pulses are then transmitted through the impulse line.

Activating the Fuel Pump Diaphragm: The pressure pulses from the impulse line create alternating vacuum and pressure conditions within the carburetor. This movement is harnessed to activate the fuel pump diaphragm, which, in turn, pumps fuel from the carburetor's fuel bowl into the intake air stream in precise quantities.

Problems that can occur if the impulse line is damaged or malfunctioning:

Loss of Fuel Delivery: If the impulse line is cracked, broken, or disconnected, it will fail to generate the necessary pressure pulses. As a result, the fuel pump diaphragm won't function correctly, leading to insufficient or erratic fuel delivery to the engine. This can result in poor engine performance, stalling, or difficulty in starting.

Lean Running: When the impulse line is damaged, it may create a constant vacuum or pressure, disrupting the fuel-air mixture's balance. This can cause the engine to run too lean, leading to overheating and potential damage to internal engine components.

Hesitation and Acceleration Issues: A damaged impulse line can result in hesitation and poor throttle response. The engine may not respond promptly when you accelerate, affecting overall performance and cutting efficiency.

Engine Damage: Prolonged operation with a faulty impulse line can lead to severe engine damage, including piston scoring and overheating, due to the incorrect fuel-air mixture.

In summary, the impulse line is a critical component in a chainsaw engine, as it ensures the precise delivery of fuel to the carburetor. Damage to this line can lead to a variety of problems, ultimately affecting the chainsaw's performance and potentially causing engine damage if left unaddressed. Regular inspection and maintenance of the impulse line are essential to keep the chainsaw running smoothly.

There is a lot more to this topic than what I have explained but I have covered the basics here.

In my experience, some of the symptoms of pulse line damaged/leakage can be:

-the engine will not start,

-engine will start but not run correctly (loss of power, over revving, under revving, uneven running, carburettor will not adjust correctly, and many more)

-engine will BOG down

This principle works for most types of Chainsaw saws, and the following also helps with Chainsaw maintenance. So, whether you are using a Stihl Chainsaw, Husquvarna Chainsaw, basically, all types of Petrol Chainsaw are valid for this principle, as well as many types of or a 2 Stroke Engine. The Electric Chainsaw, of course, escapes this whole principle!

Many thanks indeed

#ChainsawImpulseLine

#ChainsawCarburetor

#ChainsawFuelDelivery

#SmallEngineMaintenance

#ChainsawPerformance

#EnginePressurePulses

#ImpulseLineRepair

#FuelDeliverySystem

#ChainsawDiagnosis

#ChainsawTroubleshooting

#EngineRepairTips

#MaintainYourChainsaw

#ChainsawEngineProblems

#FuelSystemMaintenance

#ChainsawSafety

#SmallEngineKnowledge

#ChainsawMaintenanceGuide

#ImpulseLineFunction

#EnginePerformance

#DIYChainsawMaintenance

An issue often overlooked when a 2 stroke engine fails, such as when a Chainsaw Won't Start, is the Pulse Line. Exclusive to the two stroke engine, the Pulse Line is responsible for carrying air pressures from the engine into the carburetor and operate the fuel pump diaphragm.

If the pulse line is damaged (leaking) then the vital pressure cannot be carried to the fuel pump diaphragm resulting in the pump not working. The obvious effects of which is that no fuel can the carburetor's main jet to supply the engine. This results in engine failure.

The impulse line in a chainsaw engine plays a crucial role in the proper functioning of the carburetor. Its primary function is to create pressure pulses that help operate the fuel pump diaphragm within the carburetor. Here's how it works:

Pressure Pulses: The impulse line is connected to the engine's crankcase. As the engine runs, it generates pressure pulses in the crankcase due to the movement of the piston. These pressure pulses are then transmitted through the impulse line.

Activating the Fuel Pump Diaphragm: The pressure pulses from the impulse line create alternating vacuum and pressure conditions within the carburetor. This movement is harnessed to activate the fuel pump diaphragm, which, in turn, pumps fuel from the carburetor's fuel bowl into the intake air stream in precise quantities.

Problems that can occur if the impulse line is damaged or malfunctioning:

Loss of Fuel Delivery: If the impulse line is cracked, broken, or disconnected, it will fail to generate the necessary pressure pulses. As a result, the fuel pump diaphragm won't function correctly, leading to insufficient or erratic fuel delivery to the engine. This can result in poor engine performance, stalling, or difficulty in starting.

Lean Running: When the impulse line is damaged, it may create a constant vacuum or pressure, disrupting the fuel-air mixture's balance. This can cause the engine to run too lean, leading to overheating and potential damage to internal engine components.

Hesitation and Acceleration Issues: A damaged impulse line can result in hesitation and poor throttle response. The engine may not respond promptly when you accelerate, affecting overall performance and cutting efficiency.

Engine Damage: Prolonged operation with a faulty impulse line can lead to severe engine damage, including piston scoring and overheating, due to the incorrect fuel-air mixture.

In summary, the impulse line is a critical component in a chainsaw engine, as it ensures the precise delivery of fuel to the carburetor. Damage to this line can lead to a variety of problems, ultimately affecting the chainsaw's performance and potentially causing engine damage if left unaddressed. Regular inspection and maintenance of the impulse line are essential to keep the chainsaw running smoothly.

There is a lot more to this topic than what I have explained but I have covered the basics here.

In my experience, some of the symptoms of pulse line damaged/leakage can be:

-the engine will not start,

-engine will start but not run correctly (loss of power, over revving, under revving, uneven running, carburettor will not adjust correctly, and many more)

-engine will BOG down

This principle works for most types of Chainsaw saws, and the following also helps with Chainsaw maintenance. So, whether you are using a Stihl Chainsaw, Husquvarna Chainsaw, basically, all types of Petrol Chainsaw are valid for this principle, as well as many types of or a 2 Stroke Engine. The Electric Chainsaw, of course, escapes this whole principle!

Many thanks indeed

#ChainsawImpulseLine

#ChainsawCarburetor

#ChainsawFuelDelivery

#SmallEngineMaintenance

#ChainsawPerformance

#EnginePressurePulses

#ImpulseLineRepair

#FuelDeliverySystem

#ChainsawDiagnosis

#ChainsawTroubleshooting

#EngineRepairTips

#MaintainYourChainsaw

#ChainsawEngineProblems

#FuelSystemMaintenance

#ChainsawSafety

#SmallEngineKnowledge

#ChainsawMaintenanceGuide

#ImpulseLineFunction

#EnginePerformance

#DIYChainsawMaintenance

Комментарии

0:04:44

0:04:44

0:02:59

0:02:59

0:00:36

0:00:36

0:06:08

0:06:08

0:13:35

0:13:35

0:00:59

0:00:59

0:03:58

0:03:58

0:09:36

0:09:36

0:00:57

0:00:57

0:00:34

0:00:34

0:00:59

0:00:59

0:04:58

0:04:58

0:00:11

0:00:11

0:21:45

0:21:45

0:13:54

0:13:54

0:05:29

0:05:29

0:17:54

0:17:54

0:00:19

0:00:19

0:06:03

0:06:03

0:10:37

0:10:37

0:05:23

0:05:23

0:11:19

0:11:19

0:00:46

0:00:46

0:20:25

0:20:25