filmov

tv

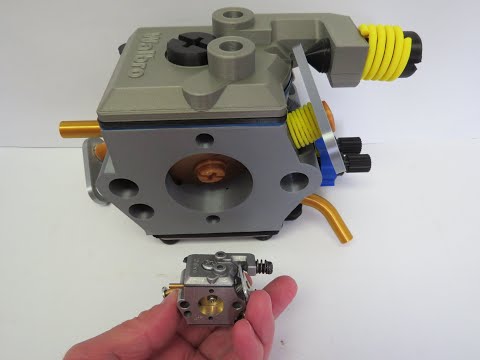

2-Stroke Carburetor Diaphragms Different Colours. This is why!

Показать описание

CHAINSAW CARBURETOR DIAPHRAGM: Different Colors Explained!

The video you mentioned highlights an important aspect of 2-stroke carburetor maintenance, specifically the different types of diaphragms used in these carburetors and how they can affect the performance of chainsaws and other 2-stroke engines. Let's delve deeper into the topic:

Rubberized Carburetor Diaphragm (Black):

Structure and Function: This diaphragm is black and known for its flexibility. It is highly efficient at pumping gasoline fuel through the carburetor.

Ethanol Sensitivity: Vulnerable to ethanol in gasoline, so it may degrade quickly when exposed to fuel with high ethanol content.

Mix Handling: Suitable for heavier fuel-to-oil mixes, like 20:1, due to its ability to move viscous mixtures.

Storage Sensitivity: Prone to deterioration if left unused for extended periods.

Acetate Carburetor Diaphragm (Various Colors):

Structure and Function: These diaphragms are available in various colors (e.g., black, blue, green) and have a shiny plastic appearance.

Cold Climate Usage: Believed to perform better in colder climates but may require more carburetor adjustments for optimal performance.

Pumping Efficiency: Less efficient at pumping gasoline fuel through the carburetor due to their harder, less flexible material.

Recommended Mix: Works better with weaker, less viscous 2-stroke oil to fuel mixtures, such as 50:1.

Ethanol Resistance: Excellent resistance to ethanol in gasoline and offers good durability.

Teflon Carburetor Diaphragm (Teflon Fiber/Glass):

Structure and Function: Made from Teflon fibers or fiberglass, these diaphragms are more flexible than Acetate diaphragms but slightly less flexible than Rubberized ones.

Pumping Efficiency: Offers a better flow volume through the carburetor compared to Acetate diaphragms.

Ethanol Resistance: Resistant to ethanol in fuel and capable of pumping heavy fuel mixes.

Quality Considerations: Diaphragm quality can vary; high-quality Teflon diaphragms tend to perform better and last longer.

Overall, the choice of diaphragm type depends on factors like the specific 2-stroke engine, the fuel-to-oil mix used, and the operating conditions. Chainsaw owners and technicians need to consider these factors when selecting the appropriate diaphragm for their carburetors. Additionally, it's important to note that the quality of aftermarket diaphragms may differ from those of well-known brands like Walbro, which can impact performance and durability.

Proper diaphragm selection and maintenance are essential to ensure that 2-stroke engines, including chainsaws, operate efficiently and reliably. Regular inspection, cleaning, and replacement of diaphragms, as needed, are crucial steps in maintaining the performance and longevity of these engines. It's important to consult the manufacturer's recommendations for your specific equipment and to follow best practices for carburetor maintenance to ensure safe and reliable operation.

v=74p9FLmIkkw&t=47s

Thank you for watching and I hope you gain something from this video.

Craig ( Owner and Creator of The Repair Specialist Channel)

#2StrokeCarburetorMaintenance

#DiaphragmTypes

#ChainsawPerformance

#EngineEfficiency

#CarburetorDiaphragms

#FuelMixRatio

#EthanolResistance

#ChainsawMaintenance

#CarburetorCare

#TeflonDiaphragm

#AcetateDiaphragm

#RubberizedDiaphragm

#EngineProtection

#FuelEfficiency

#CarburetorAdjustments

#FuelSystemCleaning

#EngineDurability

#2StrokeEngines

#ChainsawTips

#ProperMaintenance

The video you mentioned highlights an important aspect of 2-stroke carburetor maintenance, specifically the different types of diaphragms used in these carburetors and how they can affect the performance of chainsaws and other 2-stroke engines. Let's delve deeper into the topic:

Rubberized Carburetor Diaphragm (Black):

Structure and Function: This diaphragm is black and known for its flexibility. It is highly efficient at pumping gasoline fuel through the carburetor.

Ethanol Sensitivity: Vulnerable to ethanol in gasoline, so it may degrade quickly when exposed to fuel with high ethanol content.

Mix Handling: Suitable for heavier fuel-to-oil mixes, like 20:1, due to its ability to move viscous mixtures.

Storage Sensitivity: Prone to deterioration if left unused for extended periods.

Acetate Carburetor Diaphragm (Various Colors):

Structure and Function: These diaphragms are available in various colors (e.g., black, blue, green) and have a shiny plastic appearance.

Cold Climate Usage: Believed to perform better in colder climates but may require more carburetor adjustments for optimal performance.

Pumping Efficiency: Less efficient at pumping gasoline fuel through the carburetor due to their harder, less flexible material.

Recommended Mix: Works better with weaker, less viscous 2-stroke oil to fuel mixtures, such as 50:1.

Ethanol Resistance: Excellent resistance to ethanol in gasoline and offers good durability.

Teflon Carburetor Diaphragm (Teflon Fiber/Glass):

Structure and Function: Made from Teflon fibers or fiberglass, these diaphragms are more flexible than Acetate diaphragms but slightly less flexible than Rubberized ones.

Pumping Efficiency: Offers a better flow volume through the carburetor compared to Acetate diaphragms.

Ethanol Resistance: Resistant to ethanol in fuel and capable of pumping heavy fuel mixes.

Quality Considerations: Diaphragm quality can vary; high-quality Teflon diaphragms tend to perform better and last longer.

Overall, the choice of diaphragm type depends on factors like the specific 2-stroke engine, the fuel-to-oil mix used, and the operating conditions. Chainsaw owners and technicians need to consider these factors when selecting the appropriate diaphragm for their carburetors. Additionally, it's important to note that the quality of aftermarket diaphragms may differ from those of well-known brands like Walbro, which can impact performance and durability.

Proper diaphragm selection and maintenance are essential to ensure that 2-stroke engines, including chainsaws, operate efficiently and reliably. Regular inspection, cleaning, and replacement of diaphragms, as needed, are crucial steps in maintaining the performance and longevity of these engines. It's important to consult the manufacturer's recommendations for your specific equipment and to follow best practices for carburetor maintenance to ensure safe and reliable operation.

v=74p9FLmIkkw&t=47s

Thank you for watching and I hope you gain something from this video.

Craig ( Owner and Creator of The Repair Specialist Channel)

#2StrokeCarburetorMaintenance

#DiaphragmTypes

#ChainsawPerformance

#EngineEfficiency

#CarburetorDiaphragms

#FuelMixRatio

#EthanolResistance

#ChainsawMaintenance

#CarburetorCare

#TeflonDiaphragm

#AcetateDiaphragm

#RubberizedDiaphragm

#EngineProtection

#FuelEfficiency

#CarburetorAdjustments

#FuelSystemCleaning

#EngineDurability

#2StrokeEngines

#ChainsawTips

#ProperMaintenance

Комментарии

0:09:48

0:09:48

0:00:59

0:00:59

0:08:43

0:08:43

0:01:14

0:01:14

0:03:58

0:03:58

0:00:45

0:00:45

0:00:58

0:00:58

0:19:22

0:19:22

0:09:36

0:09:36

0:21:45

0:21:45

0:09:21

0:09:21

0:04:54

0:04:54

0:27:31

0:27:31

0:00:15

0:00:15

0:10:18

0:10:18

0:00:51

0:00:51

0:21:19

0:21:19

0:03:29

0:03:29

0:03:03

0:03:03

0:04:36

0:04:36

0:00:58

0:00:58

0:06:35

0:06:35

0:05:43

0:05:43

0:00:28

0:00:28