filmov

tv

Tig Welding Cast Aluminum With Helium Mix

Показать описание

How to Tig Weld Cast Aluminum

Aluminum Welding - Tips for Tig Welding Cast Aluminum parts

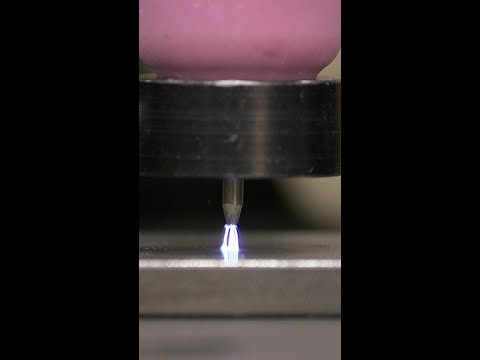

Tig Welding Cast Aluminum With Helium Mix

Tig Welding Cast Aluminum To 6061

TIG Cast Aluminum Repair Advice - TIG Welding

Tig Welding Cast Aluminum Outboard Jet Pump

TIG Welding Tips for Cast Aluminum | TIG Time

Tig Welding 60 Year Old Cast Aluminum With A Helium Mix

Tig welding Cast Aluminum To 6061

TFS: Cast Aluminum Weld Repair

7 Tips for TIG welding Aluminum

Tig Welding Old Cast Aluminum

Wait for the puddle | tig welding aluminum for beginners #tigwelding #aluminum

PAY ATTENTION TO THIS WHEN TIG WELDING ❌ #shorts

CAST ALUMINUM - A BASIC LESSON IN TIG WELDING IT

the DEFINITIVE GUIDE TO TIG WELDING BALANCE -How to TIG weld aluminum

Detailed Cast Aluminum Welding

ALUMINUM TIG TRICK #tig #welding #lifehacks

AC Balance Unleashed: Maximizing TIG Welding Performance on PrimeWeld TIG225

Cast Aluminum Weld Repair - Dremel Touchup - TIG Welding

TIG welding cast aluminum winch housing

Cast Aluminum, Cleaning Action, & 4047 Filler

TIG WELDING CAST ALUMINUM: How hard could it be?

Beginner TIG welders NEED to know this...

Комментарии

0:09:35

0:09:35

0:08:46

0:08:46

0:00:30

0:00:30

0:00:25

0:00:25

0:10:32

0:10:32

0:13:19

0:13:19

0:06:31

0:06:31

0:00:26

0:00:26

0:00:28

0:00:28

0:12:52

0:12:52

0:05:22

0:05:22

0:11:43

0:11:43

0:00:12

0:00:12

0:00:41

0:00:41

0:06:47

0:06:47

0:11:24

0:11:24

0:22:27

0:22:27

0:00:55

0:00:55

0:05:14

0:05:14

0:00:23

0:00:23

0:06:42

0:06:42

0:04:48

0:04:48

0:08:53

0:08:53

0:00:18

0:00:18