filmov

tv

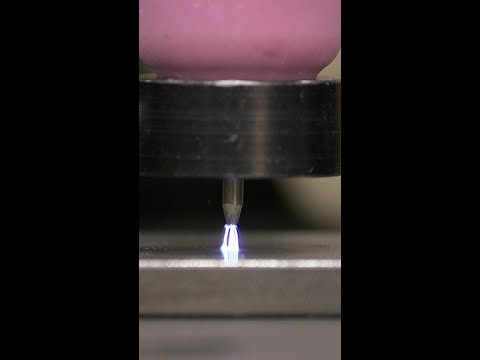

TIG Welding Tips for Cast Aluminum | TIG Time

Показать описание

#welddotcom

TIG Welding Tips for Cast Aluminum: an employee from a neighboring shop brought us a weld repair off his YZF 250 dirt bike. The repair is on a cast aluminum rear brake caliper mount that was broken during a day of riding.

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

TIG Welding Tips for Cast Aluminum: an employee from a neighboring shop brought us a weld repair off his YZF 250 dirt bike. The repair is on a cast aluminum rear brake caliper mount that was broken during a day of riding.

You can join our groups and forums, ask technical questions, answer questions in the community, look for jobs and more!

Don't miss new episodes of our podcast, please subscribe and leave us a review!

Now available on these platforms:

Brands that Support the Channel:

ALWAYS USE CAUTION WHEN UTILIZING ANY DISPLAYED TOOLS, EQUIPMENT, TECHNIQUES OR PROCESSES. IF EVER IN DOUBT, CONSULT A LICENSED PROFESSIONAL. ANY RELIANCE ON THE PRESENTED INFORMATION IS STRICTLY AT THE VIEWERS OWN RISK. EACH VIEWER EXPRESSLY AND VOLUNTARILY ASSUMES ANY AND ALL RISKS INCLUDING, BUT NOT LIMITED TO, DEATH, DISABILITY, AND/OR SERIOUS PHYSICAL INJURY RELATED TO THE USAGE OF ANY TOOLS, EQUIPMENT OR TECHNIQUES OR PROCESSES IN THE PRESENTED CONTENT. IN THE EVENT OF AN INJURY IMMEDIATELY SEEK MEDICAL ATTENTION.

Комментарии

0:06:31

0:06:31

0:08:46

0:08:46

0:05:22

0:05:22

0:13:56

0:13:56

0:21:48

0:21:48

0:08:08

0:08:08

0:00:18

0:00:18

0:12:11

0:12:11

0:10:01

0:10:01

0:00:41

0:00:41

0:19:41

0:19:41

0:00:13

0:00:13

0:07:26

0:07:26

0:00:12

0:00:12

0:05:14

0:05:14

0:00:55

0:00:55

0:07:19

0:07:19

0:00:25

0:00:25

0:09:35

0:09:35

0:13:19

0:13:19

0:11:24

0:11:24

0:12:40

0:12:40

0:21:10

0:21:10

0:00:59

0:00:59