filmov

tv

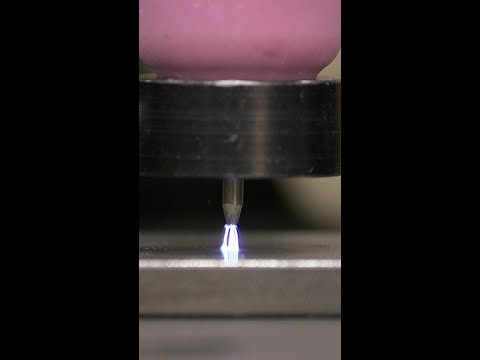

the DEFINITIVE GUIDE TO TIG WELDING BALANCE -How to TIG weld aluminum

Показать описание

One of the MOST CONFUSING things that I couldn't understand when I first started to learn TIG welding was the subject of BALANCE. So LETS MAKE THIS SIMPLE and break this down for some people getting into TIG welding. This is a subject I'm STILL experimenting with and learning about, so grab a coffee and come hang for this one, this is gonna be AWESOME🔥

CHECK OUT MY FAVOURITE WELDING GLOVES HERE

🔥🔥🔥🔥BADASS Defiant Metal Welding gloves 🔥🔥🔥🔥

🔥🔥🔥Heatwave Eye Protection🔥🔥🔥

🔥🔥🔥USE CODE ARCTIG10 FOR A DISCOUNT AT CHECKOUT!🔥🔥🔥

💛💛💛CanaWeld Tig Welding Machines💛💛💛

💚💚💚💚Everlast Tig Welders💚💚💚💚

💎💎💎My favourite Tig Welding Cups💎💎💎

CHECK OUT MY FAVOURITE WELDING GLOVES HERE

🔥🔥🔥🔥BADASS Defiant Metal Welding gloves 🔥🔥🔥🔥

🔥🔥🔥Heatwave Eye Protection🔥🔥🔥

🔥🔥🔥USE CODE ARCTIG10 FOR A DISCOUNT AT CHECKOUT!🔥🔥🔥

💛💛💛CanaWeld Tig Welding Machines💛💛💛

💚💚💚💚Everlast Tig Welders💚💚💚💚

💎💎💎My favourite Tig Welding Cups💎💎💎

the DEFINITIVE GUIDE TO TIG WELDING BALANCE -How to TIG weld aluminum

THE DEFINITIVE GUIDE HOW TO TIG WELD STAINLESS STEEL

4 Tips To Make YOU a BETTER TIG Welder

the FIRST thing you should learn tig welding

BEGINNER'S GUIDE How-To TIG Weld & Welding Basics

How do I start to learn Tig Welding?

Beginner's Guide To TIG Welding Aluminum - Pro Tips & Tricks!

a WARNING to all beginner tig welders.

Leo & Tig 🐯 Episode 23 Compilation ⭐️ | Super Toons - Kids Shows & Cartoons

Beginner TIG welders NEED to know this...

Ultimate Guide for Setting Up Your TIG Welding Machine

Learning how to TIG weld made easy

ULTIMATE TIG WELDING GUIDE!

Learn TIG Welding: A Beginner's Guide

What is the best 1st TIG rig 🤯

AC Balance Unleashed: Maximizing TIG Welding Performance on PrimeWeld TIG225

TFS: TIG Setup Simplified with LOTS of Detail

Gas Lens Kit, Tig Welding #tigwelding #car #eastwood

Beginner’s Guide to TIG Welding! Basics of TIG welding with the TIG 200 AC/DC Welder - Eastwood

SAVE YOUR TUNGSTEN Tig welding aluminum

TIG Tungsten Selection Guide: Which tungsten should I use?

the 3 BEST SETTINGS to start tig welding

Steel Tig Welding - The Complete Guide #shorts #tigwelding #steelwelding

Your Very First TIG Welds with EXTREME Detail

Комментарии

0:11:24

0:11:24

0:13:51

0:13:51

0:07:26

0:07:26

0:03:20

0:03:20

0:33:13

0:33:13

0:11:52

0:11:52

0:08:30

0:08:30

0:10:57

0:10:57

0:52:56

0:52:56

0:00:18

0:00:18

0:20:30

0:20:30

0:21:10

0:21:10

0:27:41

0:27:41

0:16:23

0:16:23

0:00:16

0:00:16

0:05:14

0:05:14

0:22:08

0:22:08

0:00:56

0:00:56

0:27:06

0:27:06

0:04:55

0:04:55

0:10:25

0:10:25

0:12:11

0:12:11

0:00:13

0:00:13

0:43:36

0:43:36