filmov

tv

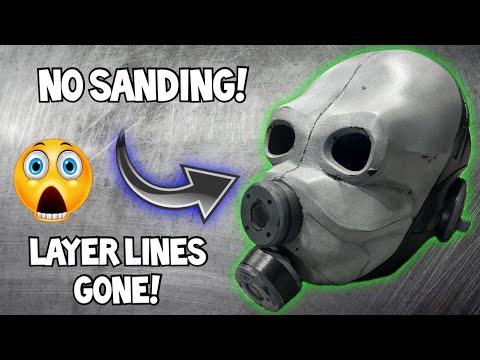

Can you smooth out 3D Prints with Beeswax?

Показать описание

This has got to be one of the crazier ways to smooth your 3D Prints but lets see if applying Beeswax Paste actually works!

Thanks to Elegoo for Sponsoring today's video!

Files from todays video

Coffee Bean Scoop by Klingy23

Original Concept by u/Azazel_Tsubuzaki

Make your own Resin 3D Printing Timelapses with Resinlapse ➜

Some links on this page are affiliate links that help out the channel.

________________________________________________

_______________________________________________

________________________________________________

________________________________________________

Thanks for watching!

#3DPrinting #Beeswax #smoothing

Thanks to Elegoo for Sponsoring today's video!

Files from todays video

Coffee Bean Scoop by Klingy23

Original Concept by u/Azazel_Tsubuzaki

Make your own Resin 3D Printing Timelapses with Resinlapse ➜

Some links on this page are affiliate links that help out the channel.

________________________________________________

_______________________________________________

________________________________________________

________________________________________________

Thanks for watching!

#3DPrinting #Beeswax #smoothing

Can you smooth out 3D Prints with Beeswax?

How to get SMOOTH 3D Prints with Acetone

The BEST Way to Smooth 3d Prints

How to Smooth 3D Prints Properly

Smooth PLA | No Sanding

How I Smooth My 3D Prints for Cosplay

How I get SMOOTH 3D Prints | EASY Slicer Settings You've Been Wanting!

Smooth Your 3D Prints FAST with UV Resin!

Smoothing 3D prints without having to sand | Remove layer lines in 3D prints my zero sanding method

How to Smooth and Prep a PLA 3D-Printed Helmet for Painting

Make Layer Lines Disappear in Seconds | The Best Way to Smooth 3D Prints

So Smooth... Ironing Settings in Cura for Perfect Top Layers - 3D Printer Pro Tips

Does Smoothing 3D Prints Improve Performance and Can You Smooth PLA?

How To Get A Smooth Top Layer | No Sanding | 3D Printing Tips & Tricks

The BEST Way to Smooth PLA Scale Models 3D Prints

XTC-3D Review / Walkthrough / Tutorial by Smooth-on that will smooth out your 3D prints

The FASTEST Way To SMOOTH 3D Prints

Smooth pla 3d prints by shaving them. Don't sand your pla, shave it.

Clean and Smooth Photoscans in Blender

How to Smooth 3D Prints - Using Power Tools to Sand PLA!

HOW TO: Smooth 3D Printed PLA Parts

How to smooth your 3D prints TUTORIAL (HD)

How to Smooth 3D Printed Parts the Easy Way

Making The Wolverine Cowl - My Fastest Way To Smooth Out A PLA Print N’stuff

Комментарии

0:13:11

0:13:11

0:01:18

0:01:18

0:06:19

0:06:19

0:10:13

0:10:13

0:02:50

0:02:50

0:06:05

0:06:05

0:19:59

0:19:59

0:06:37

0:06:37

0:12:11

0:12:11

0:04:46

0:04:46

0:02:56

0:02:56

0:06:06

0:06:06

0:11:00

0:11:00

0:05:02

0:05:02

0:10:44

0:10:44

0:11:39

0:11:39

0:02:26

0:02:26

0:07:58

0:07:58

0:01:49

0:01:49

0:09:37

0:09:37

0:08:03

0:08:03

0:10:55

0:10:55

0:05:46

0:05:46

0:15:34

0:15:34