filmov

tv

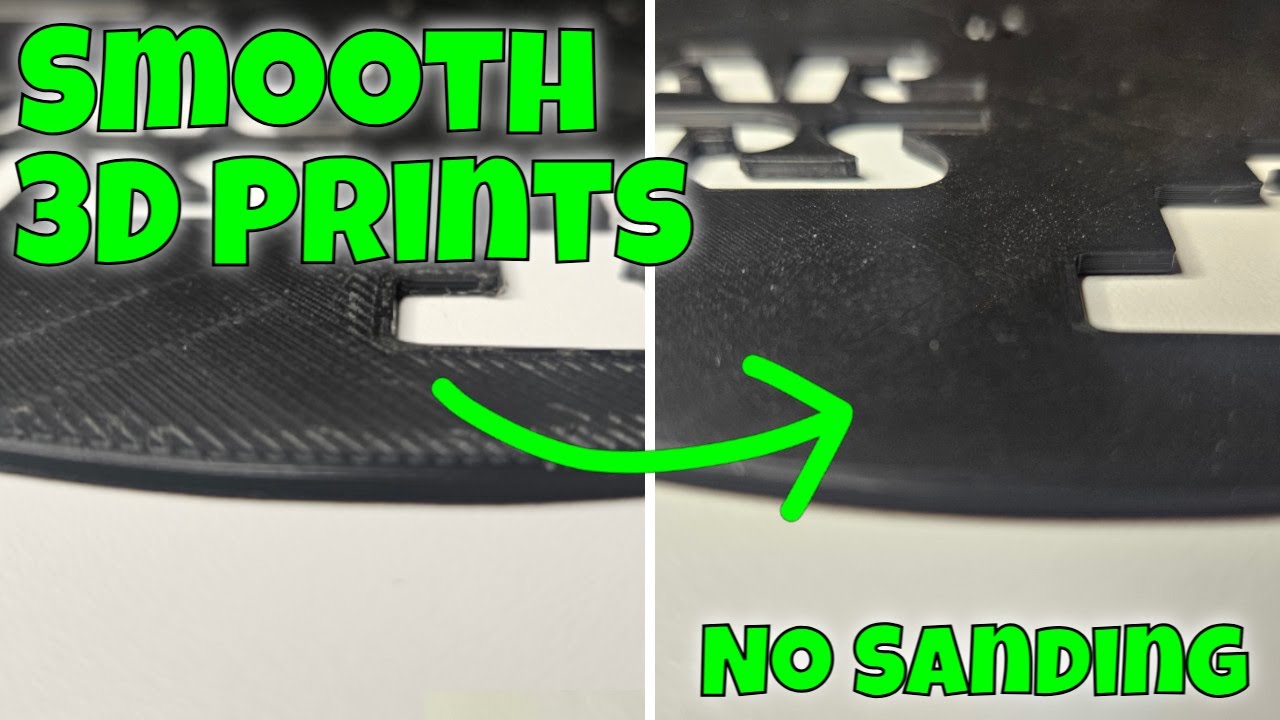

How To Get A Smooth Top Layer | No Sanding | 3D Printing Tips & Tricks

Показать описание

In this video I show you the slicer settings to use to get a smooth top layer right off the 3D printer. No sanding or painting necessary. This tutorial video shows you the steps I used to get a great finish on a 3D printed Star Wars clock.

After watching this tutorial click on the link below to download and print the free Star Wars STL that I used in this video:

Don't forget to like, comment, and subscribe for more 3D printing tips and Star Wars 3D prints!

#3DPrinting #3dprintingtips #3dprintinglife

00:00 Introduction

00:33 1st 3D print - default settings

00:49 2nd 3D print - upside down

01:20 3rd 3D print - ironing

02:09 4th 3D print - New print nozzle

02:49 5th and final 3D print

03:48 Additional 3D printing tip

After watching this tutorial click on the link below to download and print the free Star Wars STL that I used in this video:

Don't forget to like, comment, and subscribe for more 3D printing tips and Star Wars 3D prints!

#3DPrinting #3dprintingtips #3dprintinglife

00:00 Introduction

00:33 1st 3D print - default settings

00:49 2nd 3D print - upside down

01:20 3rd 3D print - ironing

02:09 4th 3D print - New print nozzle

02:49 5th and final 3D print

03:48 Additional 3D printing tip

natural ways to have a smooth and shiny hair 🌷🧸 healthy hair tips

How to get silky smooth hair at home #shorts #silkyhair #smoothhairs #youtubeshorts

How To Dance Smooth and Clean | STEEZY.CO

How To Have A Smooth, Soothing, Calming, Relaxing Voice - 6 Good Voice Tips For Speaking

How to get a BUTTERY SMOOTH golf swing!

Cake Hack: How to Get a Smooth Buttercream Finish

Bad skin habits to avoid #aesthetic #cute #korean #skincare #glowup #beautytips #beauty #beautiful

How To Get Acrylic Close and Smooth To Cuticle🔎

How to get smooth and shiny days in just few days ✨️

HOW TO EASILY GET SOFT, HEALTHY HANDS AT HOME, WRINKLE-FREE SMOOTH HANDS.

How to make your video smooth in capcut //easy//tutorial//

How To Get ULTRA Smooth FPS in Fortnite - FPS Tips and Tricks

How to get SMOOTH MUDWORK!

How to Get Smooth, Beautiful Skin

How to Get Soft, Smooth & Youthful Hands - DIY Moisturising Hand Treatment

How to get silky smooth hair in one wash | hair wash tips | how to wash hair #longhair #shorts #hair

How to Keep Your Skin Soft, Smooth, and Healthy! Dr. Mandell

🔥Silky Shiny Hair At Home/shampoo for smooth and silky hair #haircare #silkyhair #ytshorts #shorts...

SILKY SMOOTH HAIR IN JUST 1 USE 😱 | Hair growth challenge | home remedies | egg hair growth mask

10 Natural Home Remedies for Silky Smooth Feet

How to get silky smooth skin| Get rid of strawberry skin, chicken skin| keratosis pilaris

How to Make Your Frizzy Hair Silky Smooth

Body Brightening Hacks | Get SMOOTH, EVEN TONED & GLASS Skin On Your Body!

How to Get Smooth Skin

Комментарии

0:08:12

0:08:12

0:00:16

0:00:16

0:04:12

0:04:12

0:04:16

0:04:16

0:03:25

0:03:25

0:02:07

0:02:07

0:00:22

0:00:22

0:01:00

0:01:00

0:02:07

0:02:07

0:08:02

0:08:02

0:00:30

0:00:30

0:08:03

0:08:03

0:04:45

0:04:45

0:01:53

0:01:53

0:01:35

0:01:35

0:00:40

0:00:40

0:00:34

0:00:34

0:00:21

0:00:21

0:00:18

0:00:18

0:08:27

0:08:27

0:08:45

0:08:45

0:03:19

0:03:19

0:02:47

0:02:47

0:01:42

0:01:42