filmov

tv

How to Interpret DCS and PLC Symbols on a P&ID

Показать описание

=============================

▶ Check out the full blog post over at

=============================

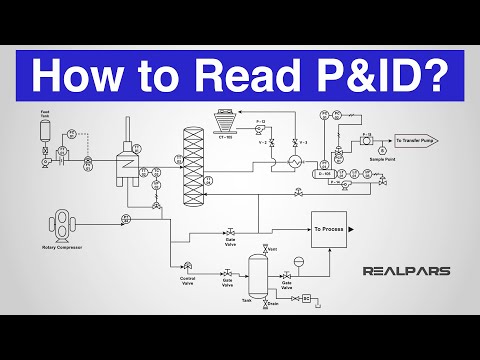

In this video, we’re going to talk about how to correctly interpret PLC and DCS symbols on a P&ID.

Anybody such as Instrumentation & Control Engineers, technicians, and maintenance personnel working on industrial plant control systems depend heavily on P&ID’s.

A P&ID is like a road map telling us what the instruments and devices are, where they are located, and how they interact with the rest of the plant.

Original symbols and terminology for P&ID’s were created long before the introduction of PLC’s and DCS’s in-plant control.

Before computers came along, process control loops were stand-alone. In other words, each process had its own individual controller.

Control rooms were massive and had sprawling control panels with lots of controllers and other devices such as strip chart recorders and switches.

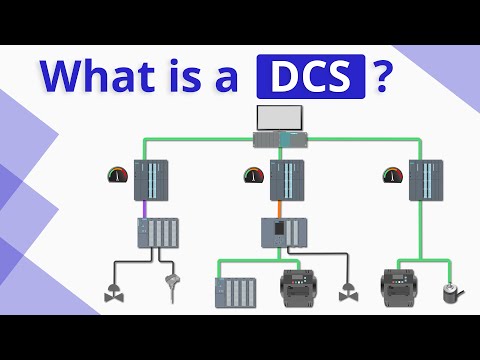

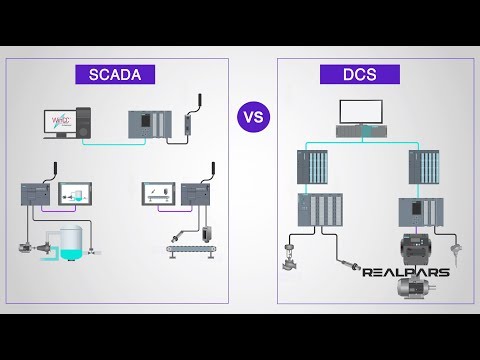

Today’s industrial processes are controlled by computerized systems using virtual controllers found in PLC’s and DCS’s.

New control rooms are filled with HMI’s and keyboards connected to a DCS or a PLC system. All of this computerization required that new P&ID symbols had to be developed.

If you recall, stand-alone instruments are indicated on a P&ID by a circle with a tag number.

The horizontal bar across the middle of the circle indicates the physical instrument resides in a primary location accessible to an operator on the main control panel.

If we take that same symbol and draw a box around it, it now means that it is no longer a physical instrument. It is now part of a shared display and shared control in a DCS.

PLC symbols don’t show up on P&ID’s nearly as often as DCS symbols. But, when they do show up, they are drawn as a diamond inside a box.

All you have to know is that the symbol represents a software instruction to perform some function in the plant.

=============================

=============================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

#P_and_ID #PLC #RealPars

Комментарии

0:06:15

0:06:15

0:09:02

0:09:02

0:08:29

0:08:29

0:02:45

0:02:45

0:05:45

0:05:45

0:09:16

0:09:16

0:11:44

0:11:44

0:13:20

0:13:20

0:11:12

0:11:12

0:11:48

0:11:48

0:04:54

0:04:54

0:10:45

0:10:45

0:09:25

0:09:25

0:11:23

0:11:23

0:17:34

0:17:34

0:05:55

0:05:55

0:13:53

0:13:53

0:00:25

0:00:25

0:01:53

0:01:53

0:06:06

0:06:06

0:06:54

0:06:54

0:07:13

0:07:13

0:00:53

0:00:53

0:00:26

0:00:26