filmov

tv

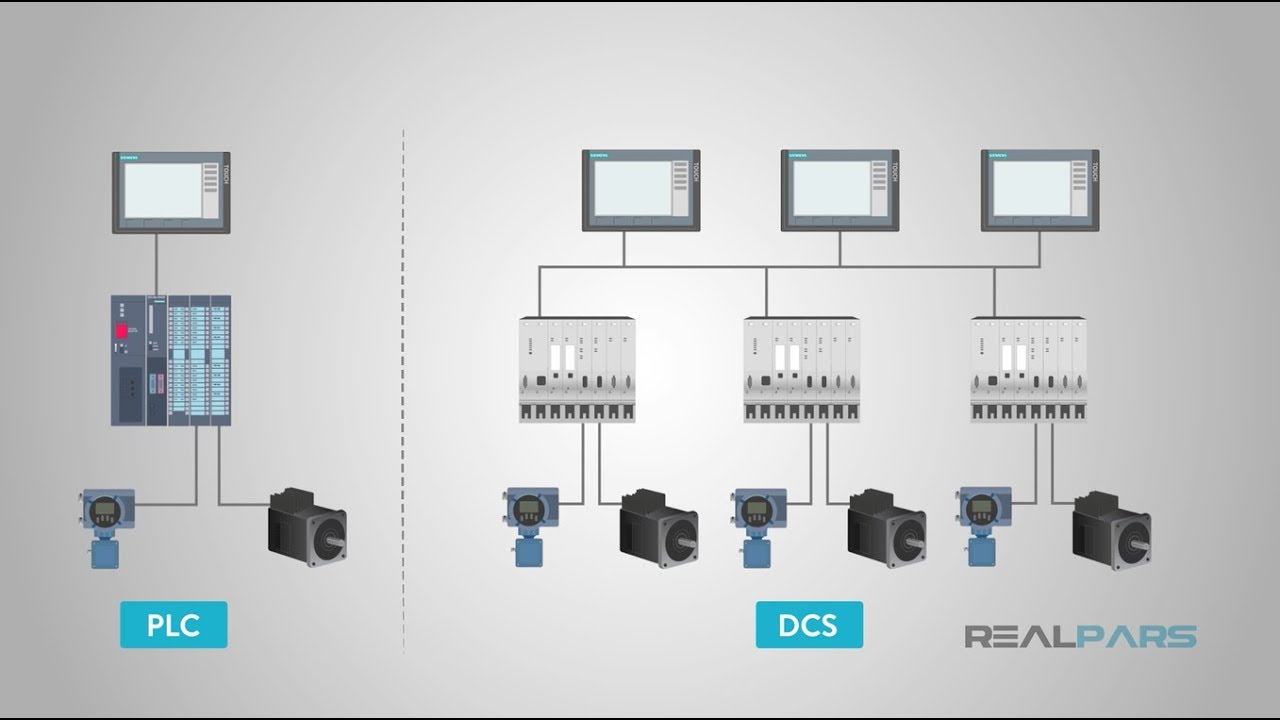

What is the Difference Between PLC and DCS?

Показать описание

==========================

In a nutshell, a PLC or programmable logic controller is a ruggedized computer used for automating processes.

A DCS or distributed control system is similar to a PLC in that is has rugged computer controllers however the DCS contains multiple autonomous controllers that are distributed throughout a system, also used for automating processes.

As you can tell, there are likely advantages and disadvantages in both systems. The take away is that with today’s technologies, either system can control an entire plant. Which system is chosen will likely take the advantages and disadvantages into account as well as system costs.

In summation, the DCS has autonomous controllers dispersed throughout the entire plant. If a controller fails, the entire plant doesn’t necessarily get impacted. It also has the onboard monitoring and control that saves development time. A single PLC is a single point of failure. You surely wouldn’t want to control an entire plant with a single PLC, however; a connected PLC system can have nearly the same security and robustness as a DCS.

==========================

Missed our most recent videos? Watch them here:

=============================

To stay up to date with our last videos and more lessons, make sure to subscribe to this YouTube channel:

=============================

=============================

#RealPars #PLC #DCS

Комментарии

0:00:45

0:00:45

0:00:59

0:00:59

0:08:11

0:08:11

0:01:02

0:01:02

0:11:55

0:11:55

0:11:16

0:11:16

0:06:09

0:06:09

0:24:11

0:24:11

0:06:34

0:06:34

0:04:11

0:04:11

0:05:15

0:05:15

0:05:12

0:05:12

0:04:46

0:04:46

0:01:45

0:01:45

0:05:55

0:05:55

0:07:02

0:07:02

0:10:43

0:10:43

0:01:17

0:01:17

0:11:26

0:11:26

0:05:14

0:05:14

0:06:46

0:06:46

0:09:17

0:09:17

0:03:14

0:03:14

0:13:38

0:13:38