filmov

tv

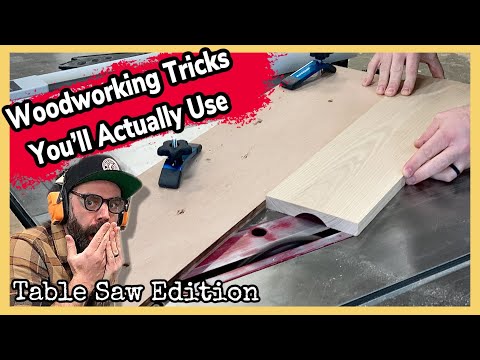

A Table Saw Trick So Crazy, It's Genius!

Показать описание

Table saw too small to break down large sheet goods? You don't have to have an expensive track saw or a DIY circular saw guide. Just use this trick to break down your materials.

HELPFUL RELATED VIDEO:

TOOLS SPECIFIC TO THIS VIDEO:

YOU CAN SAVE 10% ON STARBOND CA GLUES AND ACCELERATOR!

SAVE 10% ON OLIGHT FLASHLIGHTS, TACTICAL LIGHTS AND HEADLAMPS!

MY HAND TOOLS, POWER TOOLS, CAMERA GEAR AND MORE:

If you appreciate this content and would like to help give back FREE OF CHARGE, simply give this video a “thumbs up”, leave a positive comment, subscribe to Inspire Woodcraft’s YouTube channel and SHARE THIS VIDEO with someone who you think would enjoy it. Some of the links that we’ve provided above are affiliate links. That means that when you make purchases through those links, we earn a small commission of the sale at no additional cost to you. While we do use affiliate links where we can, we only endorse products or services that we believe in. That commission is a big part of our income, which also goes back into making more videos, so by using the links you help support what we do and for that we are very grateful.

HELPFUL RELATED VIDEO:

TOOLS SPECIFIC TO THIS VIDEO:

YOU CAN SAVE 10% ON STARBOND CA GLUES AND ACCELERATOR!

SAVE 10% ON OLIGHT FLASHLIGHTS, TACTICAL LIGHTS AND HEADLAMPS!

MY HAND TOOLS, POWER TOOLS, CAMERA GEAR AND MORE:

If you appreciate this content and would like to help give back FREE OF CHARGE, simply give this video a “thumbs up”, leave a positive comment, subscribe to Inspire Woodcraft’s YouTube channel and SHARE THIS VIDEO with someone who you think would enjoy it. Some of the links that we’ve provided above are affiliate links. That means that when you make purchases through those links, we earn a small commission of the sale at no additional cost to you. While we do use affiliate links where we can, we only endorse products or services that we believe in. That commission is a big part of our income, which also goes back into making more videos, so by using the links you help support what we do and for that we are very grateful.

Комментарии

0:07:49

0:07:49

0:03:29

0:03:29

0:14:11

0:14:11

0:07:15

0:07:15

0:03:34

0:03:34

0:11:05

0:11:05

0:04:01

0:04:01

0:21:04

0:21:04

0:06:10

0:06:10

0:01:45

0:01:45

0:07:49

0:07:49

0:05:12

0:05:12

0:13:18

0:13:18

0:04:37

0:04:37

0:11:18

0:11:18

0:06:05

0:06:05

0:00:13

0:00:13

0:12:13

0:12:13

0:16:58

0:16:58

0:09:20

0:09:20

0:00:53

0:00:53

0:05:15

0:05:15

0:04:42

0:04:42

0:08:41

0:08:41