filmov

tv

6 common things you might be doing wrong with your table saw

Показать описание

Avoid these common tablesaw mistakes to get better, safer cuts.

----------------

MAILING ADDRESS:

WWMM

448 Ignacio Blvd. #237

Novato CA 94949

----------------

Woodworking for Mere Mortals® is a registered trademark of ZRAM Media, LLC.

#woodworking #tablesaw

----------------

MAILING ADDRESS:

WWMM

448 Ignacio Blvd. #237

Novato CA 94949

----------------

Woodworking for Mere Mortals® is a registered trademark of ZRAM Media, LLC.

#woodworking #tablesaw

6 common things you might be doing wrong with your table saw

6 Common Things Anxiety Make You Say

6 Common Things Anxiety Make You Say

6 Common Mental Mistakes Making You Miserable

29 Minecraft Things You (Might) Do Wrong Every Day

If Your Body Can Do That, You're One in a Million

Your iPhone Has a Secret Button + 4 Tips to Use iPhone Like a Pro

6 Common Things That Can Harm Your Dog

MINIMALISM | 50 Common things you JUST DON'T NEED (Save money, less clutter)

10 Fun Kiddy Riddles That Stump Most Adults

12 Riddles to Check if You Can Escape from Dangers

If You See Square Waves, Get Out of the Water!

20 Facts You Didn't Know 5 Minutes Ago

12 Ways to Protect Your Home While You’re Away

10 Signs You’re Way More Intelligent Than You Realize

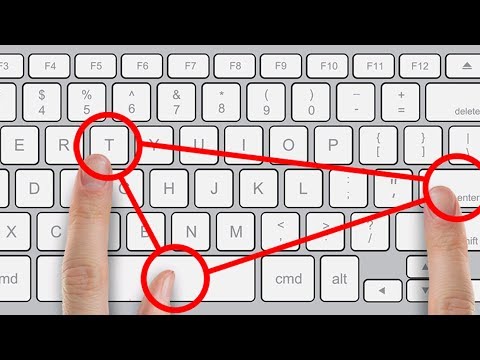

32 Secret Combinations on Your Keyboard

How Good Are Your Eyes? Cool and Quick Test

10 Questions That'll Reveal Who You Really Are

7 Swimming Rules That Will Save Your Life

15 Ways You Are Hurting Your Guinea Pig Without Realizing

6 Common Things People Forget To Put In Their Budgets | 2020 | Budgeting for Beginners

What to Do If You're in Fire Tornado Path Suddenly

10 Background Details You Never Noticed 👀 SpongeBob

11 Fun DIY School Supplies! Back to School DIY Ideas and Life Hacks

Комментарии

0:06:05

0:06:05

0:04:41

0:04:41

0:02:02

0:02:02

0:19:16

0:19:16

0:12:12

0:12:12

0:08:16

0:08:16

0:08:59

0:08:59

0:04:44

0:04:44

0:26:29

0:26:29

0:11:41

0:11:41

0:11:35

0:11:35

0:09:31

0:09:31

0:25:16

0:25:16

0:07:50

0:07:50

0:10:47

0:10:47

0:08:17

0:08:17

0:08:17

0:08:17

0:10:27

0:10:27

0:08:37

0:08:37

0:10:34

0:10:34

0:06:59

0:06:59

0:08:20

0:08:20

0:09:17

0:09:17

0:10:47

0:10:47