filmov

tv

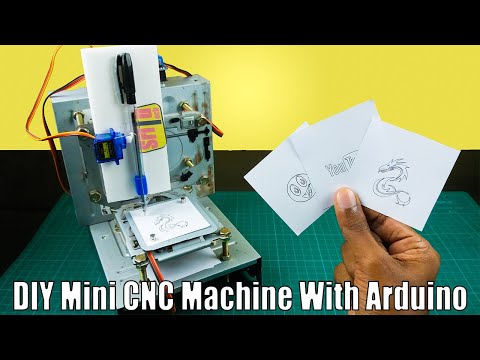

DIY Arduino CNC Machine with GRBL Shield - Setup Tutorial!

Показать описание

This video shows how to set up an Arduino, Stepper motors, and a GRBL Shield to create an inexpensive but powerful DIY CNC system!

Products used in the video:

The GRBL Shield is a great way to use G-Code to create an Arduino-based CNC machine, but setting up the software and wiring the hardware can be confusing! This video walks through every step of the process!

This video is a "foundation" video for two CNC machines we are about to do a DIY build-series of videos one: one is a DIY CNC gantry sorting machine, the other is a DIY CNC Pneumatic Engraving

machine!

GRBL Links:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Reach us / CNC Info:

Products used in the video:

The GRBL Shield is a great way to use G-Code to create an Arduino-based CNC machine, but setting up the software and wiring the hardware can be confusing! This video walks through every step of the process!

This video is a "foundation" video for two CNC machines we are about to do a DIY build-series of videos one: one is a DIY CNC gantry sorting machine, the other is a DIY CNC Pneumatic Engraving

machine!

GRBL Links:

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Reach us / CNC Info:

DIY Arduino CNC Machine with GRBL Shield - Setup Tutorial!

Mini CNC machines DIY under $50 by Arduino

Arduino CNC Shield V3 + DRV8825 - ZoneMaker

How to build a large CNC router controlled by Arduino GRBL and Universal G-Code Sender UGS

DIY CNC router | Arduino + GRBL + NEMA23

DIY Mini CNC Engraving Machine | Arduino based CNC Router machine

Making a DIY CNC machine with limited tools

DIY Dremel CNC #3 electronics, software and firmware (Arduino, aluminium profiles, 3D printed parts)

CNC Laser Engraver LONGER Ray5 20W - 4 #shorts #short #bernardotutoriales #arduino #cncmachine #diy

CNC Mill for under $100

GRBL vs Mach3: Which is better? CNCSourced

DIY Arduino GRBL CNC Plasma cutting out Harry sign

5 axis cnc woodworking machine cnc router

CNC shield V3 - Shield for Arduino

GRBL with Arduino CNC Shield – Complete Guide

Arduino CNC Shield Tutorial - Control Stepper Motors using CNC Shield V3.0

DIY Arduino Controlled CNC Mini Mill - Overview

Arduino CNC Machine Parts in 100$

How I built the Simplest CNC Machine with minimum parts possible | DIY Laser Engraver

Arduino CNC Embroidery Machine

Custom made GRBL CNC Shield + Nema 23 Stepper Motor + TB6600

DIY mini Arduino CNC drawing machine

DIY Arduino based CNC machine

Stepper Motors and Arduino - The Ultimate Guide

Комментарии

0:12:50

0:12:50

0:00:46

0:00:46

0:04:33

0:04:33

0:12:21

0:12:21

0:16:51

0:16:51

0:18:11

0:18:11

0:14:47

0:14:47

0:08:07

0:08:07

0:00:59

0:00:59

0:18:05

0:18:05

0:06:26

0:06:26

0:00:21

0:00:21

0:00:17

0:00:17

0:00:17

0:00:17

0:31:36

0:31:36

0:04:39

0:04:39

0:01:57

0:01:57

0:03:07

0:03:07

0:17:06

0:17:06

0:00:30

0:00:30

0:06:34

0:06:34

0:00:32

0:00:32

0:00:32

0:00:32

0:29:57

0:29:57