filmov

tv

How to Remove Solder | Soldering

Показать описание

-

-

Sometimes when you're soldering, you may need to remove a component from the board to rework the board. And for that, we need different tools that will help us with that job.

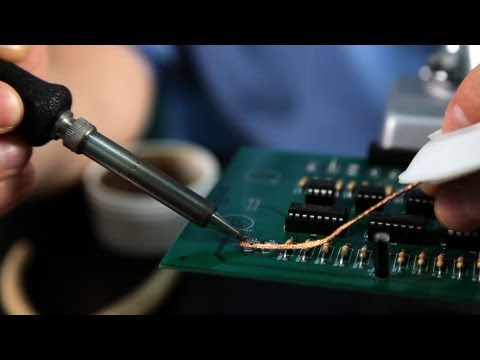

First, we need to decide what kind of component we have to work with. We have service mount components, such as this capacitor. Service mount components have no hole that passes through the board, and so we need to work on the surface using a solder wick. To use a solder wick, we first start by trimming the end flush with a wire cutter. Solder wick comes with pre-applied small amount of solder flux, but it's often helpful to have a little bit more.

Clean our tip. Now, we apply the solder wick between the part that we want to use the iron. We place our iron on top of the wick so that the wick is heated. As you can see, the solder flows into the wick. This removes the solder from one of the pads and now we're ready to use the other pad. And we can, once we remove the solder on that side, we'll be ready to remove the device.

Another type of component that's common to work with is the through-hole device. Through-hole devices have terminals that pass through both sides of the board, and so the solder also passes through that hole as well.

To remove the solder from the through-hole, we need access to both sides of the board. Both sides. And what we use is a solder sucker. A solder sucker is, basically, a vacuum tool with a plunger that provides a vacuum that we can use to suck the solder inside through the tip.

So we'll work with the tool using my left hand on the back side of the board. We'll place the tip over the pin of the part that we're looking to remove and we'll heat from the other side. Once the solder is melted, press the trigger and the solder is gone.

-

Sometimes when you're soldering, you may need to remove a component from the board to rework the board. And for that, we need different tools that will help us with that job.

First, we need to decide what kind of component we have to work with. We have service mount components, such as this capacitor. Service mount components have no hole that passes through the board, and so we need to work on the surface using a solder wick. To use a solder wick, we first start by trimming the end flush with a wire cutter. Solder wick comes with pre-applied small amount of solder flux, but it's often helpful to have a little bit more.

Clean our tip. Now, we apply the solder wick between the part that we want to use the iron. We place our iron on top of the wick so that the wick is heated. As you can see, the solder flows into the wick. This removes the solder from one of the pads and now we're ready to use the other pad. And we can, once we remove the solder on that side, we'll be ready to remove the device.

Another type of component that's common to work with is the through-hole device. Through-hole devices have terminals that pass through both sides of the board, and so the solder also passes through that hole as well.

To remove the solder from the through-hole, we need access to both sides of the board. Both sides. And what we use is a solder sucker. A solder sucker is, basically, a vacuum tool with a plunger that provides a vacuum that we can use to suck the solder inside through the tip.

So we'll work with the tool using my left hand on the back side of the board. We'll place the tip over the pin of the part that we're looking to remove and we'll heat from the other side. Once the solder is melted, press the trigger and the solder is gone.

Комментарии

0:02:19

0:02:19

0:03:20

0:03:20

0:04:55

0:04:55

0:04:00

0:04:00

0:01:23

0:01:23

0:03:38

0:03:38

0:05:08

0:05:08

0:09:38

0:09:38

0:05:06

0:05:06

0:25:10

0:25:10

0:05:40

0:05:40

0:24:04

0:24:04

0:04:06

0:04:06

0:02:09

0:02:09

0:06:13

0:06:13

0:01:15

0:01:15

0:26:37

0:26:37

0:00:47

0:00:47

0:16:11

0:16:11

0:00:39

0:00:39

0:03:46

0:03:46

0:02:39

0:02:39

0:00:54

0:00:54

0:01:10

0:01:10