filmov

tv

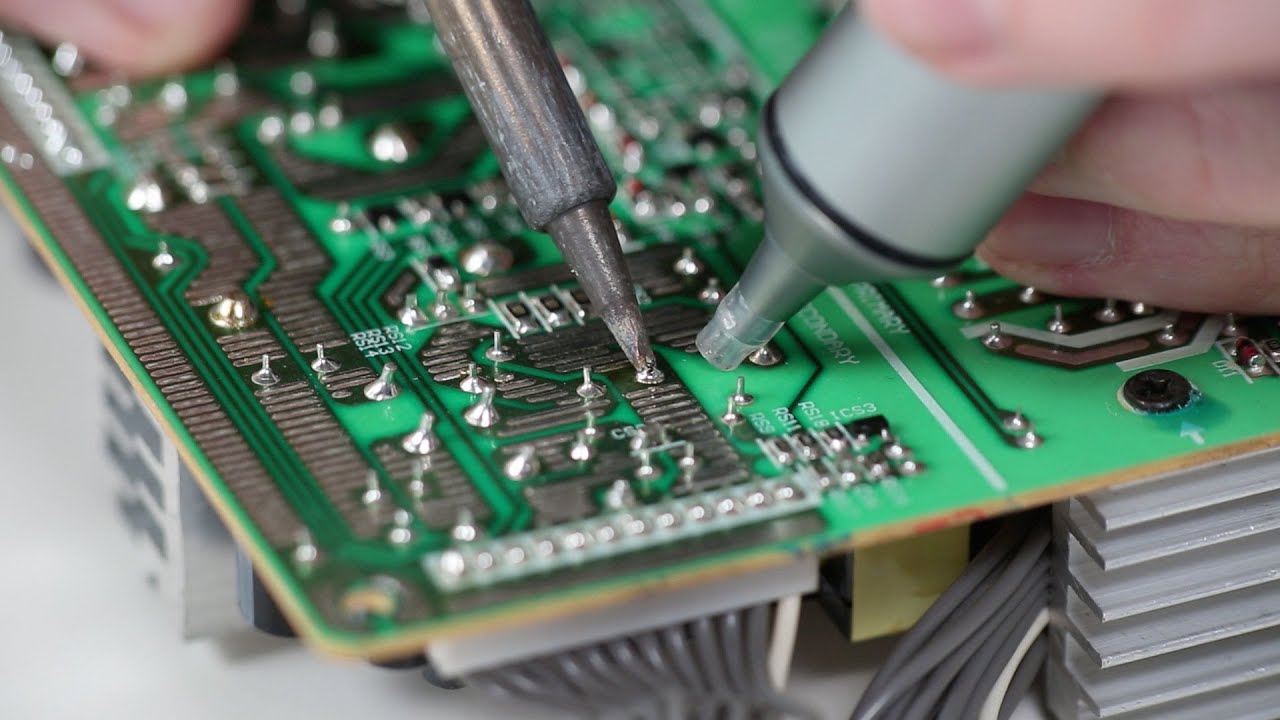

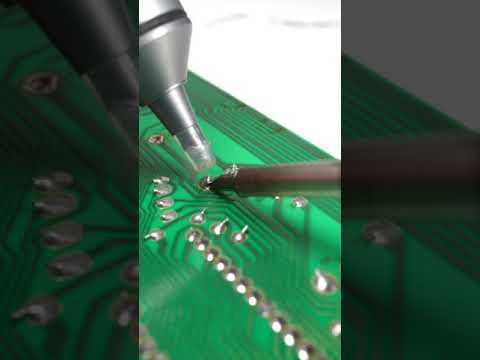

Collin’s Lab: Desoldering

Показать описание

Learning to remove a sturdy connection is almost as important as knowing how to make it in the first place. Electronics repairs, modifications, hacking, and salvage all necessitate one important skill - desoldering. Join Collin as he explains the basics of the electronic maker's undo button.

-----------------------------------------

-----------------------------------------

-----------------------------------------

-----------------------------------------

Collin’s Lab: Desoldering

Desoldering Pump - Collin's Lab Notes #adafruit #collinslabnotes

Soldering Iron Tips - Collin’s Lab Notes #adafruit #collinslabnotes

Collin's Lab: Soldering

Solder Wick - Collin's Lab Notes #adafruit #collinslabnotes #soldering

Soldering Iron Temps - Collin’s Lab Notes #adafruit #collinslabnotes

Drag Soldering - Collin’s Lab Notes #adafruit #collinslabnotes

Lead vs Lead Free Solder - Collin’s Lab Notes #adafruit #collinslabnotes

PCB Solder Jumpers - Collin’s Lab Notes #adafruit #collinslabnotes

Collin's Lab: Electronics Tools

SMD Storage - Collin’s Lab Notes #adafruit #collinslabnotes

Kapton Tape - Collin’s Lab Notes #adafruit #collinslabnotes

Collin's Lab - Surface Mount Soldering

Linear vs. Switching Power - Collin’s Lab Notes #adafruit #collinslabnotes

Wet vs Brass Sponge Tip Cleaning - Collin’s Lab Notes #adafruit #collinslabnotes

Perfboard Edge Connectors - Collin’s Lab Notes #adafruit #collinslabnotes

Digital Tweezers - Collin’s Lab Notes #adafruit #collinslabnotes

Collin's Lab: Hand Tools

Swiss Machine Pin Headers - Collin’s Lab Notes #adafruit #collinslabnotes

ACER LAPTOP SOLDERING MISTAKE #asmr #laptoprepair #F1LAB @F1LAB

how to desolder smd QFN IC

PCB Print Preview – Collin’s Lab Notes #adafruit #collinslabnotes

Solder Those Headers - Collin’s Lab Notes #adafruit #collinslabnotes

AiXun nano lead-free solder paste | new product release

Комментарии

0:03:38

0:03:38

0:00:58

0:00:58

0:00:58

0:00:58

0:05:09

0:05:09

0:01:00

0:01:00

0:00:59

0:00:59

0:00:58

0:00:58

0:00:56

0:00:56

0:01:00

0:01:00

0:09:27

0:09:27

0:00:58

0:00:58

0:01:00

0:01:00

0:08:09

0:08:09

0:01:00

0:01:00

0:01:00

0:01:00

0:00:42

0:00:42

0:00:59

0:00:59

0:05:40

0:05:40

0:00:59

0:00:59

0:00:34

0:00:34

0:00:48

0:00:48

0:01:00

0:01:00

0:00:58

0:00:58

0:00:30

0:00:30