filmov

tv

How does In-Wheel Motor Technology Work? | Four Motor Drive & Torque Vectoring

Показать описание

How does In-Wheel Motor Technology Work? | Four Motor Drive & Torque Vectoring

Video Credits (Please check out these channels also):

What are In-Wheel Motors?

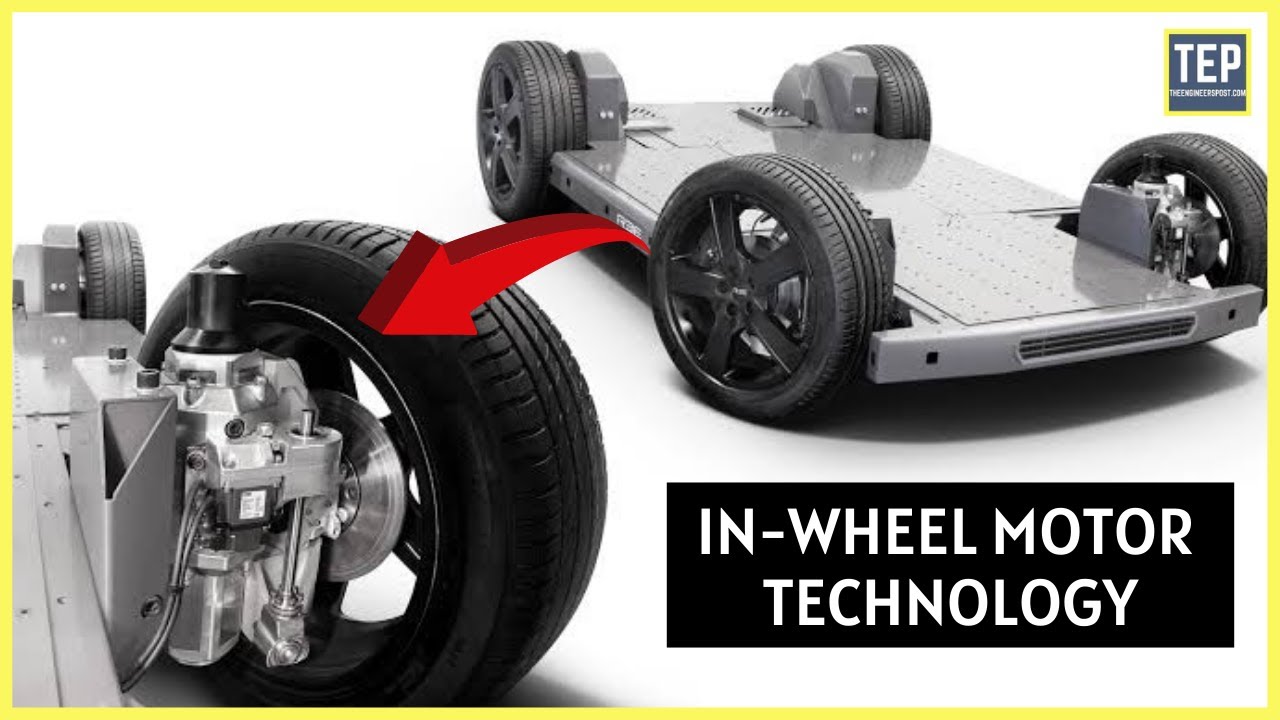

The basic principle behind a vehicle equipped with in-wheel electric motors is simple. The internal combustion engine normally found under the hood is simply not necessary. It's replaced with at least two motors located in the hub of the wheels. These wheels contain not only braking components but also all of the functionality formerly performed by the engine, transmission, clutch, suspension, and other parts.

In recent years, we’ve seen some vehicle developers moving towards powertrain configurations where the motor is mounted inside the wheel: an in-wheel motor system. And sure, these so-called hub motors or in-wheel motors come with certain benefits, but they also create some challenges.

How do In-Wheel Motors (IWM) Work?

The electric motor is installed inside the wheel and provides power to it directly, without needing any transmission. The idea of installing the motor inside the wheel rim in an EV is the right choice; in this way, it can be ensured that the full output power of the motor is available at the wheel without any mechanical transmission losses.

The number of in-wheel motors a vehicle uses can be adjusted to meet the vehicle's requirements. For instance, in most cases, two motors will supply sufficient power; If the EV is equipped with two motors in the front wheel axle, and thus the vehicle is a front-wheel drive

or in the rear wheel axle, and the vehicle is a rear-drive. However, if you're talking about an all-wheel-drive (AWD) vehicle, either an off-road truck or a performance car, obviously, that would be required to be equipped with an electric motor at each wheel.

---- Time Stamp ---

00:00 - Introduction

00:39 - How does it work?

02:39 - Design of In-Wheel Motors(IWM)

04:09 - In-Wheel Motor(IWM) Power

04:24 - Does IWM provide enough torque?

05:30 - How is IWM different than other cars?

06:14 - What is Torque Vectoring?

07:54 - Efficiency of In-Wheel Motors?

09:56 - Is this the future of EVs?

11:50 - Rivian R1T truck

13:10 - Advantages of IWM

13:53 - Disadvantages of IWM

#inwheelmotor #torquevectoring

Disclaimer:

This video is just for educational purposes only. We are not in the auto repair business nor publish automotive service manuals. This video is not reviewed or authorized by any vehicle manufacturer. This video is intended only as general guidance. Every system is slightly different, so refer to the owner’s manual of your vehicle for any specific information about your model. Remember that only proper service and repair procedures will ensure your car's safe and reliable operation.

Copyright Disclaimer:

Copyright Disclaimer under section 107 of the Copyright Act 1976, allowance is made for “fair use” for purposes such as criticism, comment, news reporting, teaching, scholarship, education, and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. Non-profit, educational, or personal use tips the balance favor of fair use.

Visit our Website for more articles:-

If you find this video useful, please share it with your friends, and If you have any questions, leave a comment we’ll respond.

Thanks for watching, and subscribe for more.

Video Credits (Please check out these channels also):

What are In-Wheel Motors?

The basic principle behind a vehicle equipped with in-wheel electric motors is simple. The internal combustion engine normally found under the hood is simply not necessary. It's replaced with at least two motors located in the hub of the wheels. These wheels contain not only braking components but also all of the functionality formerly performed by the engine, transmission, clutch, suspension, and other parts.

In recent years, we’ve seen some vehicle developers moving towards powertrain configurations where the motor is mounted inside the wheel: an in-wheel motor system. And sure, these so-called hub motors or in-wheel motors come with certain benefits, but they also create some challenges.

How do In-Wheel Motors (IWM) Work?

The electric motor is installed inside the wheel and provides power to it directly, without needing any transmission. The idea of installing the motor inside the wheel rim in an EV is the right choice; in this way, it can be ensured that the full output power of the motor is available at the wheel without any mechanical transmission losses.

The number of in-wheel motors a vehicle uses can be adjusted to meet the vehicle's requirements. For instance, in most cases, two motors will supply sufficient power; If the EV is equipped with two motors in the front wheel axle, and thus the vehicle is a front-wheel drive

or in the rear wheel axle, and the vehicle is a rear-drive. However, if you're talking about an all-wheel-drive (AWD) vehicle, either an off-road truck or a performance car, obviously, that would be required to be equipped with an electric motor at each wheel.

---- Time Stamp ---

00:00 - Introduction

00:39 - How does it work?

02:39 - Design of In-Wheel Motors(IWM)

04:09 - In-Wheel Motor(IWM) Power

04:24 - Does IWM provide enough torque?

05:30 - How is IWM different than other cars?

06:14 - What is Torque Vectoring?

07:54 - Efficiency of In-Wheel Motors?

09:56 - Is this the future of EVs?

11:50 - Rivian R1T truck

13:10 - Advantages of IWM

13:53 - Disadvantages of IWM

#inwheelmotor #torquevectoring

Disclaimer:

This video is just for educational purposes only. We are not in the auto repair business nor publish automotive service manuals. This video is not reviewed or authorized by any vehicle manufacturer. This video is intended only as general guidance. Every system is slightly different, so refer to the owner’s manual of your vehicle for any specific information about your model. Remember that only proper service and repair procedures will ensure your car's safe and reliable operation.

Copyright Disclaimer:

Copyright Disclaimer under section 107 of the Copyright Act 1976, allowance is made for “fair use” for purposes such as criticism, comment, news reporting, teaching, scholarship, education, and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. Non-profit, educational, or personal use tips the balance favor of fair use.

Visit our Website for more articles:-

If you find this video useful, please share it with your friends, and If you have any questions, leave a comment we’ll respond.

Thanks for watching, and subscribe for more.

Комментарии

0:15:11

0:15:11

0:08:38

0:08:38

![[MOBIS TECH] Versatile](https://i.ytimg.com/vi/rwKZq3VQsx4/hqdefault.jpg) 0:01:09

0:01:09

0:06:59

0:06:59

0:07:30

0:07:30

0:05:07

0:05:07

0:13:01

0:13:01

0:01:11

0:01:11

0:06:25

0:06:25

0:00:24

0:00:24

0:01:06

0:01:06

0:02:23

0:02:23

0:15:52

0:15:52

0:19:41

0:19:41

0:01:24

0:01:24

0:17:43

0:17:43

0:12:08

0:12:08

0:10:03

0:10:03

0:12:03

0:12:03

0:00:33

0:00:33

![[MOBIS TECH] e-Corner](https://i.ytimg.com/vi/hsMebu7OFwQ/hqdefault.jpg) 0:00:53

0:00:53

0:01:03

0:01:03

0:04:40

0:04:40

0:03:49

0:03:49