filmov

tv

Stainless Steel for Beginning Knife Makers

Показать описание

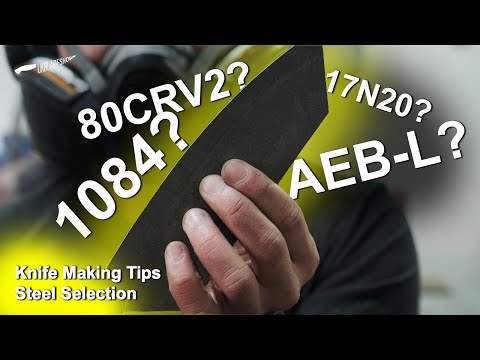

Walter Sorrells answers viewer questions on Knife Maker's Friday Five #61. Questions include good stainless steels for knife making beginners, whether Walter still uses the same forge he started his career with, and whether Tormach CNC machines can be used to mill cutlery steels.

FOLLOW ME ON SOCIAL:

Instagram: walterstactix

Twitter: @WalterSorrells

WANT TO BUY ONE OF MY BLADES?

FOLLOW ME ON SOCIAL:

Instagram: walterstactix

Twitter: @WalterSorrells

WANT TO BUY ONE OF MY BLADES?

Stainless Steel for Beginning Knife Makers

BLADESMITHING | Which Steel To Use For Knife Making | Beginner Tips

How To Heat Treat A Knife | The 4 Steps You NEED To Know

Top Ten Knifemaking Tools for the Beginner

Knife Making: Stainless Steel Hunting Knife

Carbon or Stainless Steel? A Buyers Guide For Japanese Knives

Don’t waste your money on a knife set… three knives for every kitchen

The Biggest Beginner Knife Sharpening Mistake

Why 98% of knife makers pick the wrong steel according to a metallurgist

Steel for making knives Australia: The best steel for beginners!!

Whetstone Sharpening Mistakes that Most Beginners Make

How to Heat Treat Stainless Steel for Knife Making

How To Make A Knife Without Heat Treating | The Easiest Knife To Make For a Beginner

Knife Making 101: I make a Knife with basic tools pt. 1

How To Make a Knife From a Beginners Perspective

Guide to Tool Steel for Knife Makers

Beginners Guide To Real Knife Sharpening

Cutlery | Meet the Ninja™ Foodi™ NeverDull® Premium Stainless Knife System

Is the Babish Knife Still Worth the Hype 🔪🔪 #shorts

Gordon Ramsay's Kitchen Kit | What You Need To Be A Better Chef

How To Sharpen Dull Knives

Is the Babish Knife Worth the Hype 🔪 #shorts

What thickness of steel should I use for knife making

Who knew non-stick came with toxic chemicals 🧪 #shorts #stainlesssteel #nonstick #chemical

Комментарии

0:19:09

0:19:09

0:14:50

0:14:50

0:12:13

0:12:13

0:12:13

0:12:13

0:11:45

0:11:45

0:13:05

0:13:05

0:15:35

0:15:35

0:05:53

0:05:53

0:11:07

0:11:07

0:11:15

0:11:15

0:08:25

0:08:25

0:12:23

0:12:23

0:10:04

0:10:04

0:17:10

0:17:10

0:09:34

0:09:34

0:16:21

0:16:21

0:07:52

0:07:52

0:00:29

0:00:29

0:00:49

0:00:49

0:07:02

0:07:02

0:05:58

0:05:58

0:00:52

0:00:52

0:05:55

0:05:55

0:00:47

0:00:47