filmov

tv

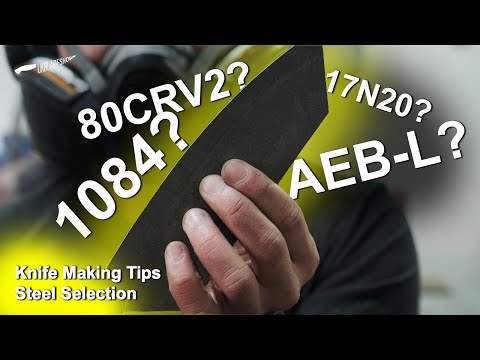

Why 98% of knife makers pick the wrong steel according to a metallurgist

Показать описание

Which is the right steel for a handmade knife? Is it 80CRV2 carbon steel or is it AEBL stainless steel? In this knife making video, Graham Clarke of Clarke Knives talks to us about knowing the difference between carbon steel, stainless steel and powder metallurgy (powder-met) steels. We talk about AEB-L stainless, 17N20, 80CRV2 carbon steel, 1084 carbon steel, and many other vanadium-type of steels.

EXTRA THANK YOU to our sponsors for making this videos happen! Kindly click the link below to check out what they specialise in!

#beststeelforknifemaking #80crv2 #1084 #aeb-l #aebl #carbonsteel #stainlesssteel #carbonsteelknife #stainlesssteelknife

EXTRA THANK YOU to our sponsors for making this videos happen! Kindly click the link below to check out what they specialise in!

#beststeelforknifemaking #80crv2 #1084 #aeb-l #aebl #carbonsteel #stainlesssteel #carbonsteelknife #stainlesssteelknife

Why 98% of knife makers pick the wrong steel according to a metallurgist

This knife was SO hard to deploy

Why 90% of knife makers use the WRONG grinding belts

Military folding knife K 98. How to make a back lock folding knife. @TimeReseT.

DON’T BUY THIS if you're a hobbyist knife maker!

Most Expensive Knife

Making a Mauser C 96 switchblade.Military folding knife. @TimeReseT.

I wish I knew THIS before I started knife making

DO NOT Make a Knife Out Of a File Till You Watch This Video-A Simple Guide To Files And Knife Making

Can You Make A Knife From Home Depot Steel?

Knife Making - Heat treating an OG Hunter. 1084 steel.

The Ultimate Knife-Making Guide: Watch Now! #DIY

Knife Making: Top 10 Things I Wish I Knew When I Started - Pt 1

Stainless Steel for Beginning Knife Makers

How to mustard etch a knife

3 reasons your knife is distorted (and WHY many makers get it WRONG)

Making an 8' Chef Knife from 80CrV2 Steel | Knife Making #shorts

Master the Art of Knife Making: Inside a Forging Class

old one For the views #damascus #patternweld #knife #forgedinfire @JasonKnightMS @AlecSteele

Knife before hardening

Forging a full tang #knife from a Rockwell USA leaf spring. See my Instagram for extended version!

AEB-L Stainless Chef As Forged #knife #bladesmithing #knifemaking #chefknife #handcrafted

#knifemaking. Plate quenching 440c stainless steel chef’s knife. #workfromhome #forging #bladesmith...

Handmade Damascus Folding Knife

Комментарии

0:11:07

0:11:07

0:00:16

0:00:16

0:11:03

0:11:03

0:19:47

0:19:47

0:07:21

0:07:21

0:00:27

0:00:27

0:17:56

0:17:56

0:17:10

0:17:10

0:11:51

0:11:51

0:02:45

0:02:45

0:00:11

0:00:11

0:00:15

0:00:15

0:08:46

0:08:46

0:19:09

0:19:09

0:00:35

0:00:35

0:12:44

0:12:44

0:00:57

0:00:57

0:00:34

0:00:34

0:00:16

0:00:16

0:00:16

0:00:16

0:00:16

0:00:16

0:00:16

0:00:16

0:00:10

0:00:10

0:00:17

0:00:17