filmov

tv

Rust Removal via Electrolysis with Terrence James

Показать описание

Electrolysis Rust Removal Tutorial

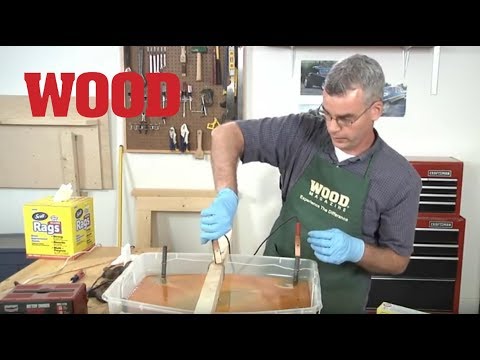

Removing Rust with Electrolysis - WOOD magazine

How to Clean the Rust with Electrolysis? Step by Step Tutorial

The Power of Electrolysis | How To Transform Rusty Tools!

Rust Removal via Electrolysis with Terrence James

Rust Removal by Electrolysis: Use in the Restoration of Machinery

How to make an electrolysis tank - The basics

How to Remove Rust with Electrolysis

Is Electrolysis better than Evapo-Rust? Let's find out!

Removing Rust In a Fuel Tank With Electrolysis - How To

RUST REMOVAL ELECTROLYSIS Old Tools #788 tubalcain

Is Electrolysis Better Than Acid For Removing Rust? Let's find out!

Best Cast Iron Rust Removal Method Using Electrolysis - GardenFork

How to Remove Rust with Electricity - Electrolysis Rust Removal - Restoration Tutorial

Electrolysis Rust Removal for Beginners

Rust Removal with DIY Electrolysis Tank.

Rust removal by electrolysis

Electrolysis - Rust removal! One day build!

Electrolysis Rust Removal | Fastest Way To Clean Rust

Electrolysis rust removal unit

Rust Removal Experiments: Electrolysis

Rust Removal - Electrolysis vs. Vinegar #309 Pt 1 tubalcain

Electrolysis Rust Removal

Improved Electrolysis For Removing Rust From Metal Detecting Finds

Комментарии

0:04:55

0:04:55

0:07:59

0:07:59

0:09:02

0:09:02

0:16:40

0:16:40

0:37:24

0:37:24

0:27:09

0:27:09

0:00:35

0:00:35

0:06:51

0:06:51

0:07:38

0:07:38

0:16:37

0:16:37

0:14:25

0:14:25

0:04:43

0:04:43

0:09:53

0:09:53

0:06:39

0:06:39

0:10:01

0:10:01

0:12:10

0:12:10

0:00:10

0:00:10

0:23:56

0:23:56

0:04:17

0:04:17

0:10:21

0:10:21

0:14:20

0:14:20

0:15:12

0:15:12

0:00:22

0:00:22

0:10:32

0:10:32