filmov

tv

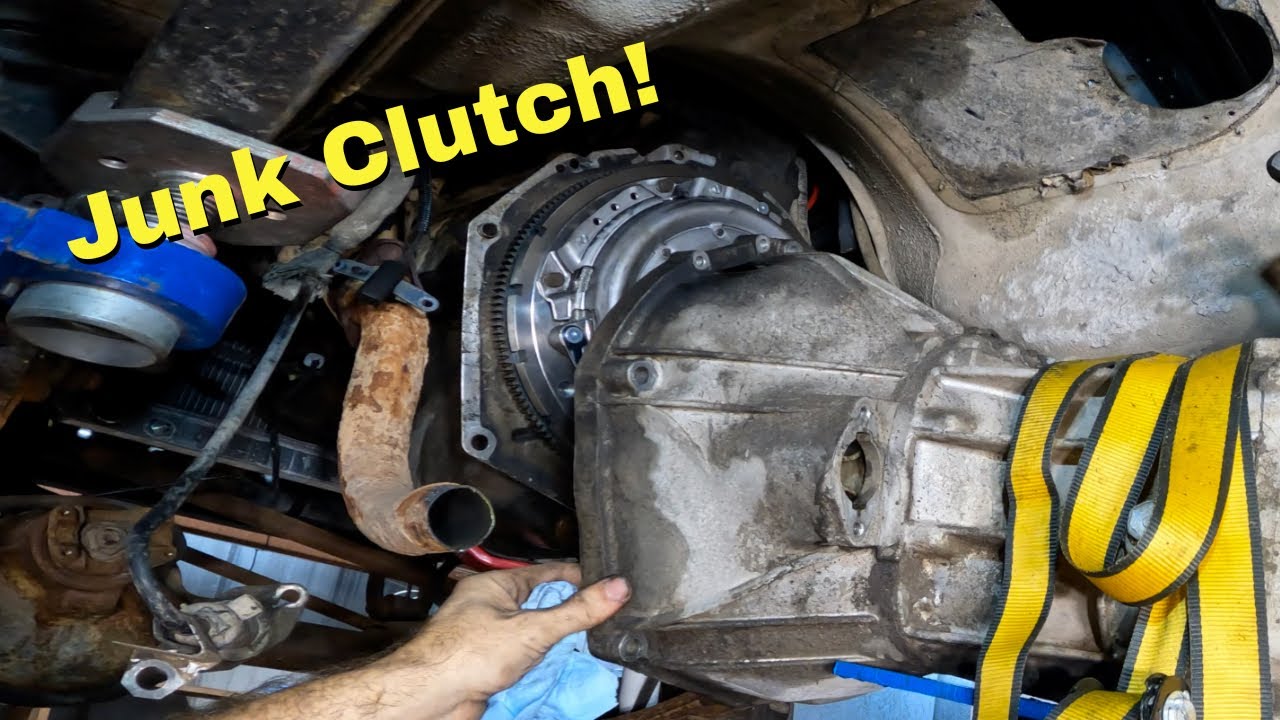

Smallest Shaft Ever! FRIED Flywheel! | Project JEEP! 1995 Wrangler YJ

Показать описание

Part 3: Old Jeeps Die HARD! Thermostatic Switch and Water Pump! 95 Wrangler 4.0

Customer States: Engine barely runs and has a severe lack of power. It also has the occasional no start or long cranking before it starts. So far I've found vacuum leaks, clogged ports, antifreeze leaks from the water pump and the electric fan is damaged. I had the fuel pump, filter, spark plugs, ignition wires, and a distributor cap and rotor. It also has a new coolant temp sensor, O2 sensor, MAP, intake temp, IAC and throttle position sensor replaced. The ECM / PCM has been replaced too. See part one.

Follow on Twitter: @RainmanRay4Real

Patreon is a "Tip Jar" I don't post much there, daily YT uploads are all that I can manage for now

Amazon List, must have for any toolbox!

My Camera Gear:

As an Amazon Associate I earn from qualifying purchases. #commissionsearned.

Also, I personally use or have used the products featured in my links and only recommended them if I feel they are of good quality.

”Intro Music by Karl Casey @ White Bat Audio”

Thanks to Jesse for making the intro and graphic for us to enjoy!!!

“All the videos, songs, images, and graphics used in the video belong to their respective owners and I or this channel does not claim any right over them.

Copyright Disclaimer under section 107 of the Copyright Act of 1976, allowance is made for “fair use” for purposes such as criticism, comment, news reporting, teaching, scholarship, education and research. Fair use is a use permitted by copyright statute that might otherwise be infringing.”

Customer States: Engine barely runs and has a severe lack of power. It also has the occasional no start or long cranking before it starts. So far I've found vacuum leaks, clogged ports, antifreeze leaks from the water pump and the electric fan is damaged. I had the fuel pump, filter, spark plugs, ignition wires, and a distributor cap and rotor. It also has a new coolant temp sensor, O2 sensor, MAP, intake temp, IAC and throttle position sensor replaced. The ECM / PCM has been replaced too. See part one.

Follow on Twitter: @RainmanRay4Real

Patreon is a "Tip Jar" I don't post much there, daily YT uploads are all that I can manage for now

Amazon List, must have for any toolbox!

My Camera Gear:

As an Amazon Associate I earn from qualifying purchases. #commissionsearned.

Also, I personally use or have used the products featured in my links and only recommended them if I feel they are of good quality.

”Intro Music by Karl Casey @ White Bat Audio”

Thanks to Jesse for making the intro and graphic for us to enjoy!!!

“All the videos, songs, images, and graphics used in the video belong to their respective owners and I or this channel does not claim any right over them.

Copyright Disclaimer under section 107 of the Copyright Act of 1976, allowance is made for “fair use” for purposes such as criticism, comment, news reporting, teaching, scholarship, education and research. Fair use is a use permitted by copyright statute that might otherwise be infringing.”

Комментарии

0:52:45

0:52:45

0:00:27

0:00:27

0:00:28

0:00:28

0:01:01

0:01:01

0:10:49

0:10:49

0:00:26

0:00:26

0:00:19

0:00:19

0:00:15

0:00:15

0:00:30

0:00:30

0:01:00

0:01:00

0:00:17

0:00:17

0:00:14

0:00:14

0:11:03

0:11:03

0:11:19

0:11:19

0:00:43

0:00:43

0:00:17

0:00:17

0:01:01

0:01:01

0:00:17

0:00:17

0:13:27

0:13:27

0:01:00

0:01:00

0:00:21

0:00:21

0:00:17

0:00:17

0:10:43

0:10:43

0:01:00

0:01:00