filmov

tv

How to Fix Heat Soak in a Carburetor

Показать описание

Heat soak in a carburetor is painfully annoying! What causes the problem, how do you fix it and what are some things to make sure it doesn't cause hot start problems. Doesn't matter if its a Holley, Edelbrock, Quick Fuel or a Quadrajet. This method works on any carburetor to keep the heat away!

#edelbrock #holley #carburetor

#edelbrock #holley #carburetor

How to Fix Heat Soak in a Carburetor

What is Starter Heat Soak, and how to fix it?

What Is Heat Soak?

QuickFix | Reduce Engine Heat Soak FREE MOD !! It's EASIER Than You Think!

Fixing Starter Heat Soak - DEI Ultra Shield MA

Jeep XJ Heat Soak Fix - Simple and Inexpensive Fix

What Does Heatsoak Feel Like? | 034Motorsport FAQ

SOLVED V6 Honda Accord Vapor Lock Heat Soak Fix | J Series Acura TL | Bundys Garage

Guide for Preventing Engine Heat Soak

Cure Heat Soak - Intake Block Off Plate

C3 Corvette Heat Soak Starter Problems Fixed Permanently! Swap Old Starter For A Gear Reduction Unit

WHAT IS HEAT SOAK? Why does the XJ have so many cooling issues?

Jeep TJ Heat Soak Fix

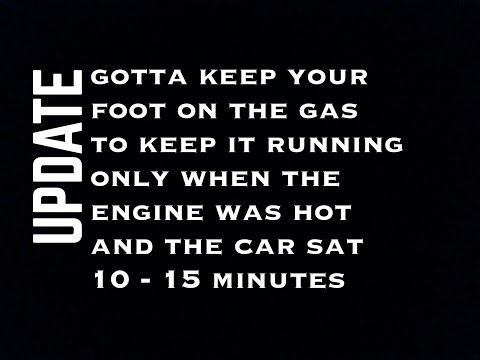

UPDATE:Heat Soak Problem Solved Honda Acura J Series V6 - Honda Accord Acura TL

Header Wrap | Heat Soak Starter issues

The Effects of Heat Soak, And How More Boost Can Hurt!

Starter Heat Soak Repair in 10 Minutes and Under 30 Bucks

Ways to FIX HEAT SOAK in a Jeep XJ! Fuel rail wrap & DIY XJ hood spacers!

Heat Soak, Is it real? Is the intake the problem?

C5 & C6 Corvette Heat Soak (How it Robs Power & how to STOP it!)

Jeep Wrangler TJ – Rough Idle/Vapor Lock (Heat Soak) CHEAP FIX

What can I do to further the prevention of Heat Soak on my B8 S4? | 034Motorsport FAQ

A New Way to Solve Heat Soak!

Stop injector Heat soak! Jeep 4.0, vapor lock and Fuel vaporization fix.DEI Fuel rail injector cover

Комментарии

0:06:49

0:06:49

0:17:29

0:17:29

0:05:07

0:05:07

0:03:46

0:03:46

0:08:14

0:08:14

0:08:11

0:08:11

0:00:49

0:00:49

0:05:18

0:05:18

0:09:38

0:09:38

0:09:13

0:09:13

0:06:39

0:06:39

0:08:47

0:08:47

0:09:48

0:09:48

0:05:36

0:05:36

0:11:43

0:11:43

0:12:33

0:12:33

0:06:10

0:06:10

0:12:07

0:12:07

0:10:25

0:10:25

0:11:04

0:11:04

0:12:14

0:12:14

0:02:33

0:02:33

0:09:55

0:09:55

0:11:48

0:11:48