filmov

tv

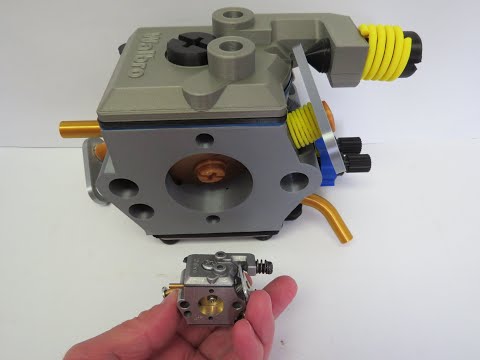

CHAINSAW CARBURETOR DIAPHRAGM: 'Fuel Pump Diaphragm' Causing BOG, Won't Start!

Показать описание

Mastery of the Chainsaw Carburetor: Unveiling the Mysteries of the Pump, Bogging Down

Very few people know this, but there is a very special Pump inside your Chainsaw Carburetor, and any malfunction of the pump and can cause a whole host of problems (bog, incorrect running and starting issues, to name just some). Powered by the fuel pump diaphragm, this pump is the heart of the 2 stroke chainsaw carburetor. The diaphragm, in turn, is powered by the 2 Stroke Engine.

Removing the fuel pump cap on the 2 stroke carburetor will expose the Fuel Pump Diaphragm. So lets now see how all of this works. Fuel is sucked through into the fuel inlet pipe where it's drawn down internally towards the carburettor body. When it gets there, the first thing it meets is the one way valve flap that it part of the Fuel Pump Diaphragm. The fuel passes this one-way valve and continues to be drawn down a second hole that is the entrance to the fuel pump chamber/reservoir, all situated underneath the Fuel Pump Diaphragm. So the pump, above, moves up and down due to alternating positive and negative pressures from the impulse line generated by the up and down movement of the piston during engine running.

Each time the negative suction pressure from the upward travel of the piston draws the fuel pump diaphragm up (via the pulse line, attached to a special connector on the fuel pump cap above the fuel pump), it sucks fuel in, underneath it, from the fuel tank. When the piston travels downwards, this sends the positive pushing pressure, via the impulse line, to the top of the diaphragm, which then pushes it downwards. This pushes the fuel out from underneath it. Upon doing so, the fuel can only go one way because of the valve flap system built into the fuel pump diaphragm. The flap that the fuel came through when the diaphragm rose up

This principle works for most types of Chainsaw saws, and the following also helps with Chainsaw maintenance. So, whether you are using a Stihl Chainsaw, Husquvarna Chainsaw, basically, all types of Petrol Chainsaw are valid for this principle, as well as many types of or a 2 Stroke Engine. The Electric Chainsaw, of course, escapes this whole principle!

v=74p9FLmIkkw&t=47s

I hope you find this video useful, and I really hope you enjoy it.

Many thanks indeed

Craig Kirkman (Owner and Creator of The Repair Specialist Channel and its Copyrighted diagrammatic content)

#ChainsawFuelPump

#ChainsawCarburetor

#FuelPumpDiaphragm

#EnginePerformance

#ChainsawMaintenance

#ChainsawProblems

#ChainsawEngine

#TwoStrokeCarb

#FuelSystem

#FuelPumpPrinciple

#EngineDiagnosis

#ChainsawTips

#ChainsawRepair

#EngineComponents

#FuelFlow

#2StrokeEngine

#ChainsawKnowledge

#CarburetorFunction

#ChainsawMechanic

#PetrolChainsaw

Very few people know this, but there is a very special Pump inside your Chainsaw Carburetor, and any malfunction of the pump and can cause a whole host of problems (bog, incorrect running and starting issues, to name just some). Powered by the fuel pump diaphragm, this pump is the heart of the 2 stroke chainsaw carburetor. The diaphragm, in turn, is powered by the 2 Stroke Engine.

Removing the fuel pump cap on the 2 stroke carburetor will expose the Fuel Pump Diaphragm. So lets now see how all of this works. Fuel is sucked through into the fuel inlet pipe where it's drawn down internally towards the carburettor body. When it gets there, the first thing it meets is the one way valve flap that it part of the Fuel Pump Diaphragm. The fuel passes this one-way valve and continues to be drawn down a second hole that is the entrance to the fuel pump chamber/reservoir, all situated underneath the Fuel Pump Diaphragm. So the pump, above, moves up and down due to alternating positive and negative pressures from the impulse line generated by the up and down movement of the piston during engine running.

Each time the negative suction pressure from the upward travel of the piston draws the fuel pump diaphragm up (via the pulse line, attached to a special connector on the fuel pump cap above the fuel pump), it sucks fuel in, underneath it, from the fuel tank. When the piston travels downwards, this sends the positive pushing pressure, via the impulse line, to the top of the diaphragm, which then pushes it downwards. This pushes the fuel out from underneath it. Upon doing so, the fuel can only go one way because of the valve flap system built into the fuel pump diaphragm. The flap that the fuel came through when the diaphragm rose up

This principle works for most types of Chainsaw saws, and the following also helps with Chainsaw maintenance. So, whether you are using a Stihl Chainsaw, Husquvarna Chainsaw, basically, all types of Petrol Chainsaw are valid for this principle, as well as many types of or a 2 Stroke Engine. The Electric Chainsaw, of course, escapes this whole principle!

v=74p9FLmIkkw&t=47s

I hope you find this video useful, and I really hope you enjoy it.

Many thanks indeed

Craig Kirkman (Owner and Creator of The Repair Specialist Channel and its Copyrighted diagrammatic content)

#ChainsawFuelPump

#ChainsawCarburetor

#FuelPumpDiaphragm

#EnginePerformance

#ChainsawMaintenance

#ChainsawProblems

#ChainsawEngine

#TwoStrokeCarb

#FuelSystem

#FuelPumpPrinciple

#EngineDiagnosis

#ChainsawTips

#ChainsawRepair

#EngineComponents

#FuelFlow

#2StrokeEngine

#ChainsawKnowledge

#CarburetorFunction

#ChainsawMechanic

#PetrolChainsaw

Комментарии

0:09:36

0:09:36

0:09:48

0:09:48

0:01:14

0:01:14

0:03:58

0:03:58

0:21:45

0:21:45

0:00:59

0:00:59

0:08:43

0:08:43

0:04:44

0:04:44

0:04:58

0:04:58

0:14:16

0:14:16

0:00:43

0:00:43

0:17:04

0:17:04

0:08:19

0:08:19

0:27:31

0:27:31

0:21:52

0:21:52

0:21:19

0:21:19

0:12:33

0:12:33

0:08:31

0:08:31

0:00:51

0:00:51

0:15:47

0:15:47

0:06:35

0:06:35

0:19:22

0:19:22

0:00:34

0:00:34

0:03:29

0:03:29