filmov

tv

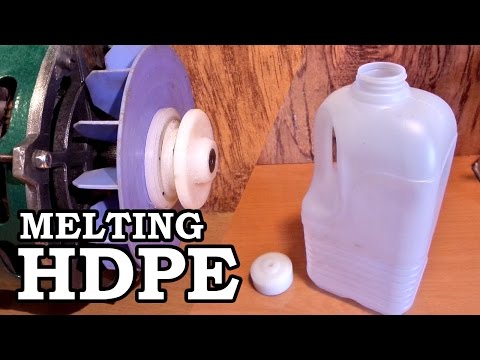

Making Plastic Rod Stock - Melting HDPE Milk Jugs

Показать описание

In this video I melt HDPE milk jugs to get a block of plastic from which I need to make a pulley for an electric motor. Because I had no decent plywood and HDPE is easily available and great pulley material.

==========

SAFETY:

Don't do anything you see me do. Stay SAFE!

Here's some things I do to make this safer, but do your own research. I ain't no chemist or doctor.

- I only use HDPE, other plastics might give nastier fumes.

- I don't try to guess if something is HDPE or not, I only use the things clearly marked.

- I only use translucent HDPE, clear or colored one might have nasty aditives.

- There are two types of HDPE, the one blown like the jugs and the one molded, like caps and buckets and such.

- I only use HDPE from milk jugs, the one made in molds might have aditives to make it flow better.

- I Keep it the right temperature and work in a well ventilated room.

- I only do this rarely, constant exposure to fumes has risks.

You... should not do this!

==========

SAFETY:

Don't do anything you see me do. Stay SAFE!

Here's some things I do to make this safer, but do your own research. I ain't no chemist or doctor.

- I only use HDPE, other plastics might give nastier fumes.

- I don't try to guess if something is HDPE or not, I only use the things clearly marked.

- I only use translucent HDPE, clear or colored one might have nasty aditives.

- There are two types of HDPE, the one blown like the jugs and the one molded, like caps and buckets and such.

- I only use HDPE from milk jugs, the one made in molds might have aditives to make it flow better.

- I Keep it the right temperature and work in a well ventilated room.

- I only do this rarely, constant exposure to fumes has risks.

You... should not do this!

Комментарии

0:04:14

0:04:14

0:00:20

0:00:20

0:00:08

0:00:08

0:00:57

0:00:57

0:00:15

0:00:15

0:00:16

0:00:16

0:00:34

0:00:34

0:00:10

0:00:10

0:01:19

0:01:19

0:00:12

0:00:12

0:01:26

0:01:26

0:02:23

0:02:23

0:00:16

0:00:16

0:00:10

0:00:10

0:08:02

0:08:02

0:00:15

0:00:15

0:00:42

0:00:42

0:00:30

0:00:30

0:00:12

0:00:12

0:04:58

0:04:58

0:00:42

0:00:42

0:00:07

0:00:07

0:00:42

0:00:42

0:00:25

0:00:25