filmov

tv

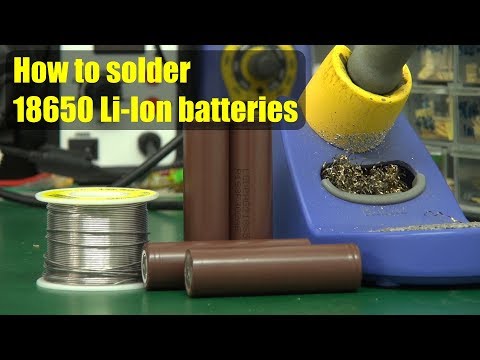

How to solder 18650 Li-ion batteries to make a custom-made battery pack (Ebike)

Показать описание

How to solder 18650 Li-Ion batteries

How to quickly solder 18650 Li-Ion Batteries with a soldering iron

How to solder 18650 Li-Ion batteries

how to solder 18650 perfectly every time

How to solder 18650 Li-Ion batteries

How to solder 18650 Li-ion batteries to make a custom-made battery pack (Ebike)

Best Soldering 18650 Lithium Cell Tutorial - NO Welding, Just Solder!

How To Soldering Lithium Battery

[2020] How to Solder 18650, AA, 9v, or ANY Other Battery (To Make Battery Packs) | Safe & Quick

How to solder li-ion battery without overheating

How to Solder 18650 Li-Ion Batteries Safely without Overheating

Lithium-ion Battery Soldering Tricks

How to solder 18650 Li-ion Batteries

SOLDERING 18650 BATTERY - SAFER & MORE CAREFUL

3 Easy Steps to Solder 18650 Battery

Spot Welding 18650 Cell

The quickest method to solder 18650 cells

Does soldering 18650 cells kill them??

How to solder lithium batteries#shorts

Soldering 18650 Batteries (DO IT RIGHT)

How To Solder 18650 Battery Cells Correctly Without Spot Welding Tools

Lithium Cell Soldering How To Solder 18650 Li-Ion Battery

How to solder 18650 Li-Ion batteries

18650 lithium battery flux paste welding solder paste vs rosin welding #soldering #shorts

Комментарии

0:00:20

0:00:20

0:01:55

0:01:55

0:14:19

0:14:19

0:01:24

0:01:24

0:07:40

0:07:40

0:13:03

0:13:03

0:02:55

0:02:55

0:00:36

0:00:36

![[2020] How to](https://i.ytimg.com/vi/Zx7d5yJdWp0/hqdefault.jpg) 0:03:08

0:03:08

0:00:22

0:00:22

0:00:58

0:00:58

0:01:00

0:01:00

0:00:16

0:00:16

0:09:54

0:09:54

0:01:39

0:01:39

0:00:13

0:00:13

0:01:23

0:01:23

0:04:32

0:04:32

0:00:34

0:00:34

0:06:46

0:06:46

0:10:43

0:10:43

0:00:29

0:00:29

0:00:19

0:00:19

0:00:23

0:00:23