filmov

tv

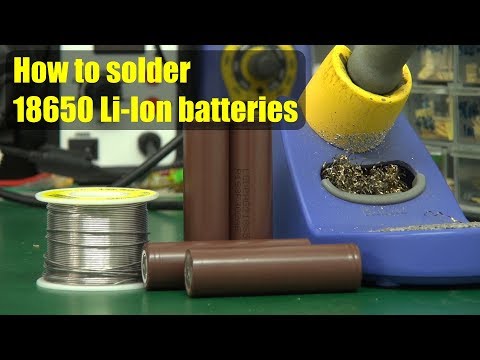

SOLDERING 18650 BATTERY - SAFER & MORE CAREFUL

Показать описание

DISCLAIMER: I am not responsible for any injury and/or damage from anyone watching this video.

Please follow my instructions at your own risk.

Soldering 18650 can be dangerous because lithium-ion batteries are not heat tolerant and they can explode or combust by fire.

How to solder 18650 batteries safer and more careful:

Step 1: Make surface rough using sand paper or utility knife.

Step 2: Add blob of solder to each surface first

Step 3: Combine and melt both solder blobs together quickly

Please be careful using this technique, the key is to NEVER heat-up the battery too much.

Thank you for watching. Please LIKE and SUBSCRIBE

#solder18650 #solderbattery #18650battery

Please follow my instructions at your own risk.

Soldering 18650 can be dangerous because lithium-ion batteries are not heat tolerant and they can explode or combust by fire.

How to solder 18650 batteries safer and more careful:

Step 1: Make surface rough using sand paper or utility knife.

Step 2: Add blob of solder to each surface first

Step 3: Combine and melt both solder blobs together quickly

Please be careful using this technique, the key is to NEVER heat-up the battery too much.

Thank you for watching. Please LIKE and SUBSCRIBE

#solder18650 #solderbattery #18650battery

SOLDERING 18650 BATTERY - SAFER & MORE CAREFUL

Can you solder 18650 batteries? Q&A#3

Danger of soldering Li-ion batteries

How to solder 18650 Li-Ion batteries

How to solder 18650 Li-ion batteries to make a custom-made battery pack (Ebike)

Beginner’s guide to building safe 18650 batteries

how to solder 18650 perfectly every time

HOW TO SOLDER 18650 BATTERIES - SOLDERING CELLS WITH TABBING WIRES⚡️

How to solder 18650 Li-Ion batteries

The Best Way to Remove Nickel Tabs on Battery 18650 Cells

Does soldering 18650 cells kill them??

LG 18650 Li-Ion Cell Teardown and Explanation LGEAS31865 2200mAh

How to apply solder on to 18650 lithium ion cells. Relaxing solder work.

No Soldering Needed: Connect Wires to Lithium-Ion Batteries Easily #diy #tech #lifehacks

How To Solder 18650 Battery Cells Correctly Without Spot Welding Tools

How to Spot Weld Nickel Strips onto 18650s - DH30 Portable Spot Welder

DIY Battery Spot Welder - Demonstration & Explanation

All you need to know about 18650 batteries

How to quickly solder 18650 Li-ion batteries with a soldering iron

Electric Danger of Lithium Ion 18650 - Battery Fires Exposed - Possible DIY Solution

How to solder 18650 cells (TS-100, fuses, busbars)

Generation 2 18650 soldering, 120 VAC power supply

Soldering 18650 Batteries: How Hard Can It Be?

How to solder li-ion battery without overheating | Soldering tips. #soldering #diy #solderingtips

Комментарии

0:09:54

0:09:54

0:05:47

0:05:47

0:00:36

0:00:36

0:00:20

0:00:20

0:13:03

0:13:03

0:19:38

0:19:38

0:01:24

0:01:24

0:04:47

0:04:47

0:14:19

0:14:19

0:00:29

0:00:29

0:04:32

0:04:32

0:01:44

0:01:44

0:07:22

0:07:22

0:00:48

0:00:48

0:10:43

0:10:43

0:08:31

0:08:31

0:07:40

0:07:40

0:05:29

0:05:29

0:08:39

0:08:39

0:12:49

0:12:49

0:02:37

0:02:37

0:00:42

0:00:42

0:00:51

0:00:51

0:00:22

0:00:22