filmov

tv

How To Properly Apply Threadlocker

Показать описание

We have noticed the bolts failing on some of the machines we have built (such as the CNC and Plastic Injection Machine), and after further investigation we found the issue to be in the way we applied the Loctite Threadlocker.

We made a quick video to demonstrate how to properly apply the thread locking fluid (thread locker) to threads in order to save you the trouble of failing screws in your builds.

Ways To Support Our Channel:

We built a CNC Machine

We built a Wire EDM

We built an EDM Sinker

We built a Plastic Injection Machine

We built an Anodizing Setup

We built CNC Router

#Loctite #Machine #Bolts #Nuts #DIY #CNC #tools #homemachineshop #shop #mechanical

We made a quick video to demonstrate how to properly apply the thread locking fluid (thread locker) to threads in order to save you the trouble of failing screws in your builds.

Ways To Support Our Channel:

We built a CNC Machine

We built a Wire EDM

We built an EDM Sinker

We built a Plastic Injection Machine

We built an Anodizing Setup

We built CNC Router

#Loctite #Machine #Bolts #Nuts #DIY #CNC #tools #homemachineshop #shop #mechanical

How To Properly Apply Threadlocker

In the Lab with LOCTITE® - Proper Use of Threadlocker

How to Use Loctite for Beginners

In the Lab with LOCTITE® - Proper Use of Threadlocker with Blind Holes

How To Apply Loctite | Balisong Maintenance Tips

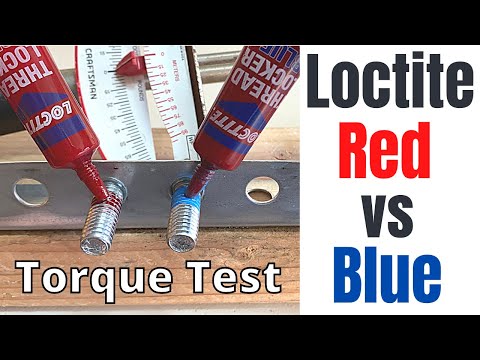

The Honest TRUTH - How Much Stronger is Loctite Red than Loctite Blue?

How to PROPERLY Use Threadlocker 😮 #shorts

How to Properly Use Threadlocker (Semi or Permanent)

How to Disassemble & Remove Loctite Red High Strength Threadlocker

PTFE Tape or Loctite 55 | How to use PTFE tape and Loctite 55

Which 'Red' Threadlocker is Best? Let's find out!

Everything You Need to Know About Loctite

Threadlocker Removal

Thread locking | nut locking

Thread locker on blind holes - how to do it properly

Which loctite do I need? How to choose the correct Threadlocker Loctite Permatex IT MATTERS!

Best Damaged Thread Repair? Let’s Settle This! Heli Coil, TIME-SERT, E-Z LOK, JB Weld, HHIP, Loctite...

How to use PTFE tape - Ultimate Handyman DIY tips

Grease, Lubricant, Threadlock, Fibregrip: What & Where Should You Use It?

Should Anti-Seize Be Applied On Spark Plug Threads?

STRIPPED THREADS? THIS MECHANICS TRICK / HACK WILL SAVE YOU TIME, MONEY, AND LOTS OF FRUSTRATION

How & Where To Use Grease, Lubricant & Threadlock On Your Mountain Bike – The Complete Guide...

How & Where To Use Grease, Fiber Grip, Threadlock + Anti Seize On Your Bike

#short Loctite is not only the leader in threadlocking technology, but they created it!

Комментарии

0:01:05

0:01:05

0:03:36

0:03:36

0:01:23

0:01:23

0:03:09

0:03:09

0:03:29

0:03:29

0:03:05

0:03:05

0:01:01

0:01:01

0:01:51

0:01:51

0:01:16

0:01:16

0:07:39

0:07:39

0:09:24

0:09:24

0:09:11

0:09:11

0:08:55

0:08:55

0:10:45

0:10:45

0:00:48

0:00:48

0:09:30

0:09:30

0:14:51

0:14:51

0:02:10

0:02:10

0:12:41

0:12:41

0:03:25

0:03:25

0:03:17

0:03:17

0:12:13

0:12:13

0:06:25

0:06:25

0:01:00

0:01:00